Glazed Porcelain Floor Tile 600x600mm CMAX-TL6005

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

- Option:

- 600x600mm

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Brief Introduction

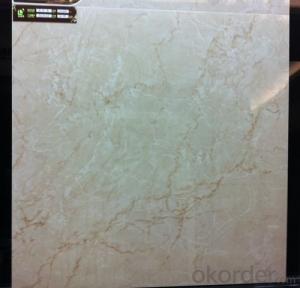

Glazed Porcelain Tile CMAX-TL6005 is one of the popular colors in the present market. Just like other series, it could be used for interior floor and wall for apartment, villa, as well as other public areas, due to its unique antique feel image and texture. The glazed porcelain floor tile is wildly used in Europe, North America and Middle East.

Product Features

Glazed Porcelain Floor Tile

Grade AAA available only

Mainly the basic size is 600*600mm, which could be cut into 30*60mm, 30*30mm, 15*60mm.

Standard export packing: Pater Carton+ Wooden Pallet

Fast production arrangement

Marketing support on samples, catalogues as well as carton designing

Professional sales team for the whole purchasing process.

Product Specification

Tile Type: Glazed Porcelain Floor Tile

Quality standard: GB/T4100-2006, ISO13006, ISO9001

Water Absorption Rate: 《0.5%

Breaking Strength: 》 1300 N

Rupture Modulus: 》40 MPa

Length and Width Tolerance: ±0.1%

Edge Straightness: ±0.5%

Slip Resistance: 》 0.5

Resistance to Staining: Class 3.

Packing Information (For 27.5 Tons heavy 20’Fcl)

For 600x600mm, 4pcs/Ctn, 40 Ctns/Pallet, 840 Ctns/20’Fcl, 1209.6m2/20’Fcl

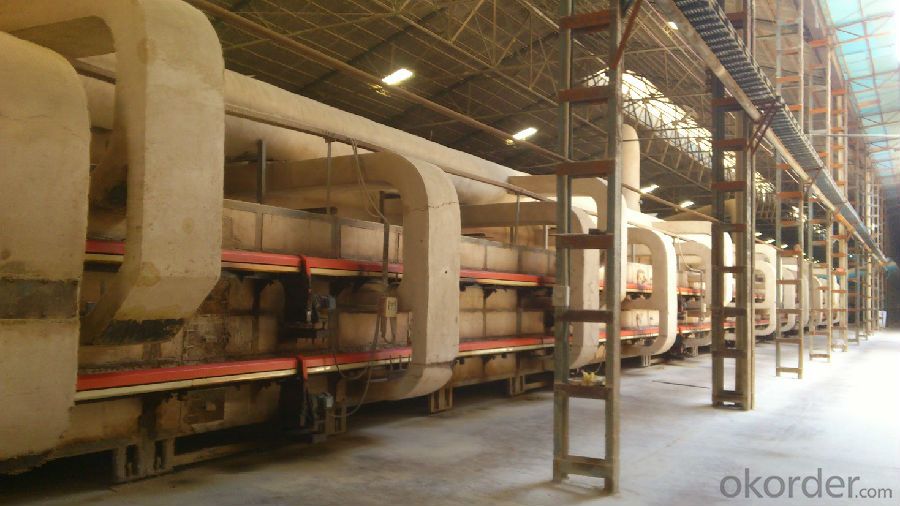

Production Line & Package

FAQ

1. For Glazed Porcelain Floor Tile, what is the difference from polished porcelain tile?

—— For Glazed Porcelain Floor Tile, there is a special glaze layer on the tile surface, which makes the surface feel matt or rough, while the surface of polished porcelain tile is glossy and smooth.

2. What is the delivery time after we paid the deposit?

—— Normally, we shall get all items ready for loading within 3 weeks after we get the deposit or the formal Letter of Credit. For orders which demand cutting job, it will take a longer time.

3. For the delivery term, could you go with CFR our port?

—— Yes, of course. We have very good relationship with those big shipping company, such as COSCO, MSC, HPL etc. We have a very professional logistic team to arrange the shipping issue well.

4. Could you company supply polished porcelain tile?

—— Yes. We could supply various kinds of polished porcelain tile, with size 60*60, 80*80, 100*100 and 60*120.

- Q:i am getting my kitchen done over in 2 weeks cost is not a factor i cant decide to do tiles or harwood flooring which is better for the kitchen. i have two kids 2 and 5

- I prefer ceramic tile in a kitchen simply because every hardwood floor I've ever had was slippery if liquid was spilled on it. There are issues with keeping the grout clean as someone pointed out, but good maintainence will take care of that. Another factor you'll want to consider is the look of everything else. If you are going with wood cabinets, hardwood floors might be too much. Or if you have a tile countertop and backsplash, tile flooring might be too much. Look at both and compare them to the other elements you have choosen for the kitchen, that will probably make the decision very easy. But either, ceramic tile or natural hardwood, both add a lot of value to your home and look beautiful.

- Q:my dad is does tile. He has quite a bit of leftover tile from various jobs. Is it possible that we can recycle tile?

- There are ARTISTS who use CERAMIC tile scraps.

- Q:I have a few ceramic tiles on my kitchen backs plash that do not match my new kitchen color. Can I paint them? If so, how? Thank you.

- Hi! Just saw this post on another forum: Painting tile will work IF... * It's very clean/dry/dull, and the grout is the same. * Soooo, sand the tile with a 220-sponge, remove all dust, and inspect/repair grout. Lightly wash other areas too let dry. * Prime all areas with BIN (shellac-based) primer from Zinsser.

- Q:My parents want to re-tile their bathroom. My dad says he can use regular tiles in the bathroom, bathroom being the floor and the open-shower walls(the only thing stopping the water spillage is plastic and fabric on a rail), but my mom says it needs bathroom tiles and bathroom grout for the job. Any help would definitely be appreciated!!!

- We put ceramic tile and grout in our bathrooms and kitchen. Never heard of bathroom tiles. The kids get the whole bathroom wet when they bathe and we haven't had any problems with it in over 10 years.

- Q:how do you clean up ceramic tiles? they dont seem to shine but look very dull whenever i clean it with water and soap. is there a product i can use to clean them and at the same time leave them shining?

- most all tile manufactures will tell u to clean tile with just a damp mob and warm water. it would really help if u had soft water.

- Q:i was pouring grout on my tile floor and it dryed too fast. how can i get rid of it?

- Sand it off. The upper layers should be fine but you'll have trouble the closer to the tile you get. You don't want to scratch that new tile. A quick tap from a chisel may release it from the tile surface but you runt the risk of cracking the tile. Good luck!

- Q:I am installing commercial tile and I have no idea what tool is used to cut this kind of tile, it easily breaks if its bent too hard. I need to cut curved areas on this tile and I have no idea what too to use. Please help! ;)

- If you are talking about vinyl tile you can use an hair drier to soften the tile so you can cut it without it crumbling. Use a curved tin snip or a utility knife to cut after softening. You should be able to lay it flat on the floor, soften it, scribe it with the utility knife, and then snap it. If you are talking about ceramic tile you should use a tile saw. You can rent one for about $60/day. You can buy one in Home Depot or Lowe's for about $90.

- Q:Only whole tiles are used. How many tiles are neither diagonal tiles nor edge tiles?

- If there are 121 tiles and both tiles and floor are square, this means there are 11 by 11 tile used on the floor (square root of 121 is 11) So if we exclude the edges, this means we have 9 by 9 tiles And there are 9 tiles on each diagonal but the one in the center is shared so we have total of 9+9-1=17 tiles on diagonals of this inner tiles with 9 by 9 So for 9 by 9 tiles we have 9x9=81 tiles and excluding 17 tiles on diagonals; the answer is 81-17=64 tiles.

- Q:We had a piping problem in out house and we need to find self stick tiles. We honestly cant find any good places to find these tiles. If anyone can give good suggestions on where to find some self stick tiles? I live in dearborn Michagan.

- Do you have a Lowes in your area?

- Q:Has anyone ever used the spray glaze you can use to paint ceramic tile? I have some ugly green tile on the walls in my bathroom, and I don‘t want to get into busting it out. I saw it used on HGTV, but I want to know if any REAL people have used it? If so, was it expensive? Easy to use? Did it run? I will take any other ideas anyone has for an inexpensive way to do something with this horrible green!

- I have never seen a really successful do it your self reglazing job. It looks ok when it is first applied but will not hold up to normal use. it scratches or peels. also for tile it does not look natural because the grout gets painted as well as the tile

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Glazed Porcelain Floor Tile 600x600mm CMAX-TL6005

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

- Option:

- 600x600mm

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products