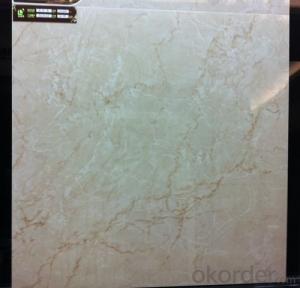

Glazed Floor Tile 300*300mm Item No. CMAXE3677

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1683 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Brief Introduction

Glazed Floor Tile 300*300mm, CMAXE3677 is one of the popular models of 300*300 mm glazed floor tile, which is wildly used for floor of kitchen and bathroom as well as balcony and bedroom. These tiles could create an antique feel of classic European life, just like living in the old times of nature and pastoral life.

Product Features

Glazed Floor Tile

Only Grade AAA available

Strict control on glazing, water absorption rate as well as color shade and straigtness

Competitive price

Standard export packing: Pater Carton+ Wooden Pallet

Fast delivery

OEM service could be offered

Product Specification

Tile Type: Dry-Pressed Tile, Silk Printing Glazed Surface

Quality standard: GB/T4100-2006, ISO13006, ISO9001

Water Absorption Rate: 3% -- 6%

Length and Width Tolerance: ±0.1%

Surface Smoothness: ±0.15%

Edge Straightness: ±0.15%

Packing Information (For 27.5 Tons heavy 20’Fcl)

11pcs/Ctn, 18.5kg/Ctn,1472Ctns/20’Fcl, 1457.28m2/20’Fcl

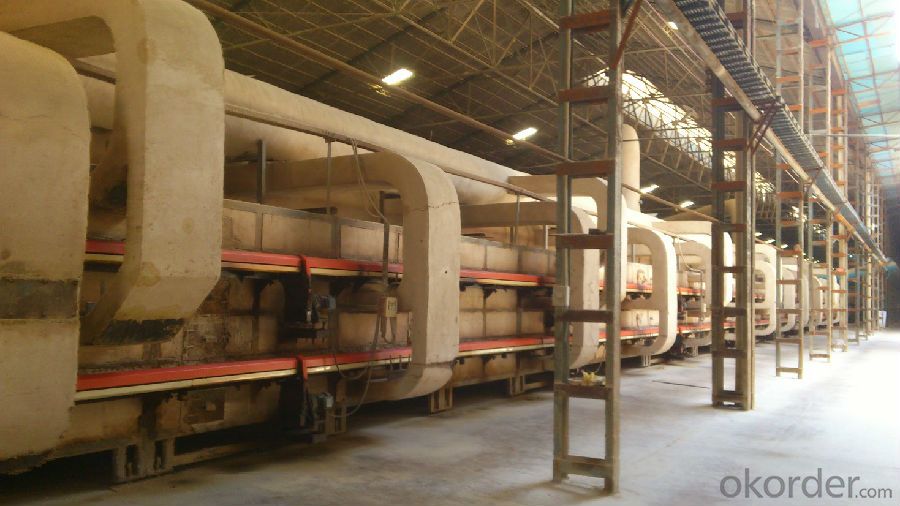

Production Line & Package

FAQ

1. Could you company supply polished porcelain tile?

—— Yes. We could supply various kinds of polished porcelain tile, with size 60*60, 80*80, 100*100 and 60*120.

2. What is the delivery time after we paid the deposit?

—— Normally we shall get all items ready for loading within 3 weeks after we get the deposit or the formal Letter of Credit?

- Q:I am tiling my bathroom and in the process of re-tiling the shower stall. I removed the old plastic liner there and now some of the glue remains on the greenboard. Also, some of the green part of the board is ripped of from when the glue came off with the old liner. Some of the paper is flakey in spots. I pulled off some of the loose pieces, but there is more. Now, I‘m an amateur. I was told to use some grout sealer to go over the greenboard. However, since there are flakey pieces of paper from the greenboard on there still, should I simply remove as much as I can before sealing and tiling? Will the seal glue these flakey pieces down and make them secure for tiling? What is your advice? Many thanks!

- First of all, remove the greenboard that was under the tile. Replace it with cement board-that's a MUCH better subbase for tile. The peeling you experienced with the board that's up will cause you problems down the road. If you can't remove the greenboard, then your best bet is to sheet over the greenboard with 1/4 cement board, available in the flooring department at Home Depot. You will need to transition the tile where it meets the drywall outside the shower. In no case do you want to apply tile to the damaged greenboard. It will not last.

- Q:Tao Shiya tile how, the quality of how?

- No matter what kind of tiles, its quality identification is nothing more than wear resistance, water absorption, hardness, color, size and other standards, so you can use the following method to determine its quality. Glazed tiles: with rubber hammer or fingers gently tapping the various positions of glazed tiles, such as the same sound, that there is no sandwich; if the sound is different, the internal may be mezzanine, unqualified. Polished tiles: the same quality of polished tiles, from the side to see the relatively thin brick quality, and good quality polishing polished brightness is relatively high. Whole body bricks: weigh the weight of the brick, the same size of the brick, the weight is better than the light. Good quality brick surface fine, smooth. Ultra-fine powder tiles; ultra-fine powder brick is a new series of tiles. Its distinctive feature is that each piece of pattern is different, but the whole is very coordinated, natural. There is a kind of imitation microfine brick on the market, rough look like a small powder brick, but careful observation will find that it is almost the same pattern every piece. Antique tiles: with nails on the surface of the brick draw, good quality brick will not leave traces. In general, the quality of the antique brick is better quality. Listen to the sound: hand tapping the tiles, if the sound crisp, sweet, then that ceramic porcelain high degree of porcelain, good quality; if the sound boring, cloud turbidity, it shows that the sintering degree is not enough, poor texture. In general, the slower the water, indicating that the greater the density of the floor tile, the better the quality; the other hand, the faster the water, indicating that the floor of the small density, the quality of the tiles on the back of the tiles, watching the water spread after the speed, Poor.

- Q:New handyman project involves putting ceramic tile on bathroom walls. Never tried this before. Any tips or suggestions? What about a web site with do it yourself directions?

- Most important get a decent tile cutter plan out your tiles so you have an equal cut at each end ,use tile spacers and good adhesive most of all like most DIY take your time

- Q:I need to know if flexbond is the best stuff to use for this type of job for a do it yourselfer. I have never worked with this stuff. I have only used regular thin set mortar in the past. Is it hard to work with?? And to lay the tiles this large do I have to butter the mortar on or can I just trowel it onto the plywood floor?Thanks, Fran

- Flexbond has the same consistency as other thin sets. So it isn't any harder to work with. As far as applying it to the back of the tiles and the floor, I typically don't. If you have high or low spots in the sub floor, use an appropriate floating material to feather those spots out before you lay any tile. You can use something as simple as a 4' level and just lay it on the floor moving it in every direction to look for high/low spots. That is the only reason to apply it to the back side, to fill low spots. Use a 1/2 notched trowel to spread the flexbond. The key is to not make it too soupy when you mix it. If you do, the thin set tends to drop some, typical to air out of a balloon (if that makes sense to you). That will be what makes tiles not adhere fully. You can tell this by tapping on the tile the next day. You will here the hollow sound. If you have that scenario, remove that tile and reset it before grouting. Here's a tip to make the grouting easier. Keep a bucket of water and sponge with you as you lay the tile. Wipe the excess flexbond off the tiles and from the spots between the tiles where the grout will be. If the flexbond is down 1/4 from the top of the tile, that's fine.

- Q:Just moved into a house with tile floors, I have fiber mopped, stick-vac‘d, wet mopped them and they still feel gritty on my bare feet. Anyone have any suggestions or will they always feel dirty?

- The tiles are probably anti slip so they will naturally feel a bit rough to your bare feet. Also, if the tiles are brand new then it will take a while for you to sweep and mop away the dust left from the tile glue and grouting. The best way I've found to remove this fine grit from tiles is, unfortunately, to get down on your hands and knees with a dish sponge and a bucket of hot soapy water and physically scrub them - at least twice, more likely 3 or 4 times.

- Q:Have a tiled half wall that I dont like, and as I neither know how to remove tiles or if how to drill through a tile can anyone help?

- A bit for drilling concrete works well , also they make a spade bit that can be used for tile or glass, If it is a thick tile i would use a bit and a drill with the sds chuck as it won't slip. You can get the bits at Home Depot of just about any hardware/lumber supply store. the drill with the sds chuck can be rented if you do not have one.this is if you are trying to anchor something into the tiled wall. If you want to remove the tile, you are better to pull the tile and drywall off at the same time , if you try removing the tile alone it will damage the drywall and you'll have to float the whole thing or remove it anyway. Good Luck !

- Q:ok, i tiled my kitchen with the sticky tiles (not expensive ceramic ones or anything like that) then sealed it with a clear tube of sealant. it is about 3 or 4 days later, and the floor looks like crap. the sealer left behind a nasty tar trail or something. While the tile looks glossy and beautiful the places i sealed are dull and def noticable. How do I get rid of the excess???? I've tried scraping, it just don't work. help me!!!!

- No one here can really help you without knowing the following: It depends upon exactly what material the tiles are made of that you installed yourself and what type of sealant that you used. Contact the place you bought the sticky tiles from, to start with. If that doesn't help you get the answer you need, contact the sealant company(info. should be on the tube, somewhere)

- Q:how do i do the measuring and lay out on a 10 foot by 6 foot floor when laying the tiles diagonally?

- A 10x6 room requires 60 square feet of tile to cover the floor. On a normal square to the walls pattern, I would order 10% more tile to cover waste. On a diagonal pattern, you will have more waste. I would order 15% to 20% more tile to cover waste. To set up to lay the tile, I start by picking the most obvious sight line in the room - maybe from the next room through the door and chalk a line perpendicular to the far wall along that sight line and parallel to the side wall. Then you chalk a line 45 degrees wall to wall through the center point of the center of the first line. This is your 45 degree pattern. Chalking a line wall to wall 90 degrees from the second chalk line through that same center point gives you your grid pattern to set your tile from. Ignore the first line - that was for reference only - line two and three are the lines you set your tile from. Set out tile dry with spacers to see if you like the effect. I will sometimes set out all of the whole tile possible in the room and walk around to see if it looks good. If it doesn't look right or you end up with too small pieces along the edges or in the doorways, you can move your initial start point and rechalk your lines.

- Q:I wanted to remove three lines of bathroom wall tiles without distrubing other surrounding tiles. These tiles were fixed on cement around 5 months back.. now we can see cracks on these tiles (different color)..

- hammer bust that tile in the middle of it. Remove pieces. Don't remove tile from edges or may damage neighboring tile.

- Q:We have an installer, whom seems to be doing it wrong. I can‘t find any website that explains how to install tile the way he is doing it. Can you tell me if this sounds correct?First he puts mortar on the bare cement floor, then put down versa-bond or a bonding agent.. and then he puts more mortar on the tile and then lays it down.. Does this sound right to you?Thanks

- Versa bond is a thin set brand name. It s a good thin set too.So I m not sure what you mean by a bonding agent. And putting it on the back of the tile is a method ( slow method) of setting and leveling tile. I would have to know the trowel sizes that he / she is using before passing a final judgement. I would use a bigger notched trowel on the floor and just a thin smooth coat on the tile back. Both methods will level tile and ensure a full coat of thin set for tile to bond well to the floor. Any questions you can e mail me through my avatar and check my qualifications there. GL

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Glazed Floor Tile 300*300mm Item No. CMAXE3677

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1683 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products