Glass Storage Jar HD105

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

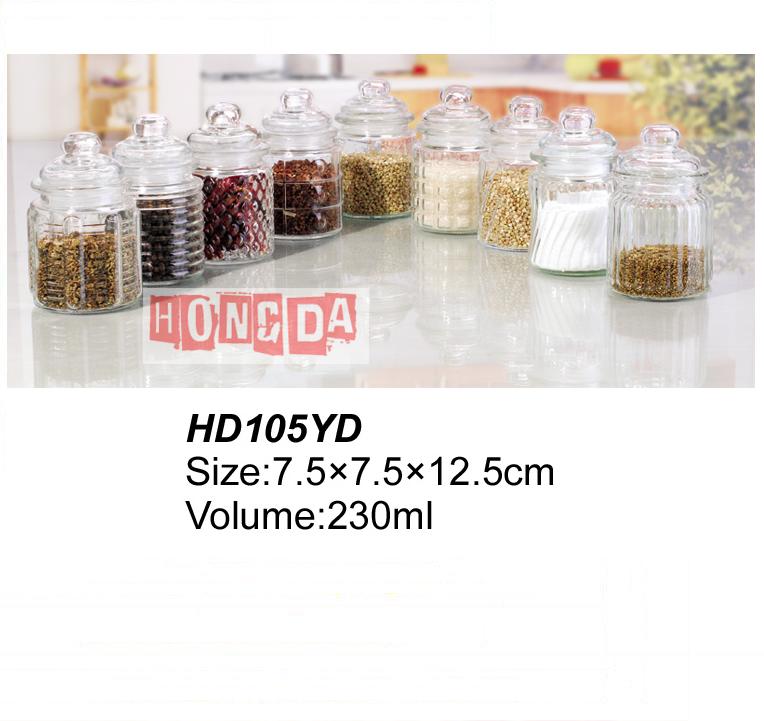

This product is a pressing cover, using food grade rubber sealing ring is to prevent moisture, insects and other advantages, using high quality raw materials, green environmental protection, convenient cleaning. Lines clear, beautiful and generous. There is a high ornamental value.

(Filler belonging to display products, not in the sales range)

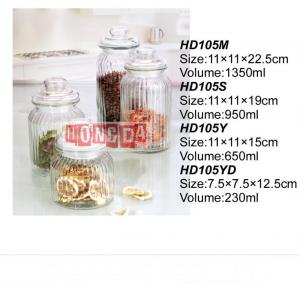

HD105M Size:11x11x22.5cm Volume:1350ml

HD105S Size:11x11x19cm Volume:950ml

HD105Y Size:11x11x15cm Volume:650ml

HD105YD Size:7.5x7.5x12.5cm Volume:230ml

- Q:What are the raw materials for making glass?

- Sandstone fused glass has a bright luster, and has a good transparency, acid resistance and mechanical strength.

- Q:How do you make the glass, please? What is the raw material?

- You can melt the sand and then try to remove the magazine and turn it into glass.

- Q:There are several appearances of the quality defects of ordinary flat glass

- The wave bar, also called the water line, is the most vulnerable and the most serious defect in the appearance defects of glass. It can cause optical distortion of glass and cause visual fatigue or visual illusion of the observer. There are many reasons for the wave reinforcement, mainly due to the backward production process and chemical composition and excessive impurity content.

- Q:What material does PCB have?

- There are many kinds of copper clad laminates. According to different material can be divided into paper substrate, glass cloth substrate and synthetic fiber board; according to the different binder resin is divided into phenolic, epoxy, polyester and polytetrafluoroethylene; use can be divided into general and special type.

- Q:Method for cutting thick glass

- Cutting glass with abrasivesThe original A. plus sand saw diameter 95300 ~ 400mm, 1 ~ 2ram thick brass, iron plate made of circular plate, rotated, injection abrasive (silicon carbide, corundum, corundum and so on) and the slurry water mixed, with some of the side of the glass to the saw cutting force.B. with ordinary abrasive cutting compared with ordinary wheel, diamond grinding wheel, it is difficult to cut thin products, cutting losses, grinding wheel wear, wheel but cheap, especially in dry cutting, it is common to the advantages of grinding wheel cutting.C. wire cutting with multiple jointless wire (wire or piano wire = O.05 ~ 0.2mm), can also cut about 100 sheets. The edge of the abrasive material is added to the workpiece with a certain amount of pressure, and the edge is milled and cut. Because of the grinding surface cutting, the margin is very small, you can get high-precision cutting.D. abrasive jet machining method and principle of the same blast form, but the use of abrasive powder (average particle diameter of 27 m, with a tiny belly) jet nozzle (spraying gas as carbon dioxide, nitrogen and compressed air), shot edge pores, edge cut glass plate. The impact of the abrasive is so small that it will not damage the glass. This method can process thin glass plates.

- Q:What is the difference between acrylic board, lotus board, organic board and PVC board?

- Organic boards are called organic plates, PS boards, PS organic boards, PS boards, light panels, light box boards, GPPS boards, benzene boards, color boards, etc. some places are simply called organic glass. People have different opinions. In fact, organic boards are different from organic glass.

- Q:Why are most of the chemical instruments made from glass?

- Of course, the glass is colorless and transparent is also very important, the front of some people said that the glass is cheap, I would like to deny, in fact, this glass is not often in general glass, high temperature, the cost is much higher than that

- Q:Which is the best solar water heater tube?

- The surface of the vacuum heat collecting tube is smooth and clean, the pipe body has no spots, no air lines, no scratches and no film forming. (this phenomenon will affect the collection efficiency and beauty).

- Q:What materials do we need to make glass septic tanks?

- Glass reinforced septic tanks require glass fiber and unsaturated polyester resin as the main raw materials:

- Q:What is acrylic material?

- Acrylic properties;1. excellent transparencyColorless transparent plexiglass plate, light transmittance of more than 92%2. excellent weather resistanceAdaptability to the natural environment is very strong, even for a long time in sunlight, wind and rain will not change its performance, anti-aging properties, and can also feel comfortable in the outdoor use.3. good processabilityThe utility model is suitable for mechanical processing and easy thermal forming, and the acrylic plate can be dyed, and the surface can be painted, silk screen or vacuum coating.4. excellent comprehensive performanceAcrylic plate has many varieties, rich colors and excellent comprehensive properties. It provides diversified choices for the designers. The acrylic board can be dyed, and the surface can be painted, silk screen or vacuum coating.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Glass Storage Jar HD105

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords