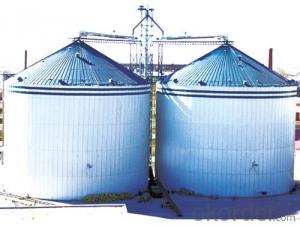

Germany Technology Cement Silo Cement Industry Equipment

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Germany Technology Cement Silo Cement Industry Equipment

Specification for Coment Silo Industry Equipment

A: For size below 200ton cement silo, we suggest to use bolt assembly or welding type silos.

B: For size over 200ton cement silo, we suggest to use our spiral folding type silo.

| Please Click It to Get More Information → | Size Below 50ton Cement Silo | ||

| Processing Method | Spiral Folding | Bolt Assembly | Welding |

| Materials | Hot Galvanized Steel Can Use Special Materials Required | Carbon Steel Can Use Special Materials Required | Carbon Steel |

| Capacity | 200-7000ton/silo | 50-200ton/silo | Below 50 ton |

| Bottom Type | Flat or Hopper | Hopper | Hopper |

| Foundation Type | Concrete or Steel Structure | Concrete or Steel Structure | Concrete,Steel Structure |

| Application | Cement Storage | Cement Storage | Cement Storage |

| Features | 1) Spiral Folding Treatment Silo has the Max Sealing 2) Big Storage Volume 3) Short Poject Period, Sea Delivery Cost Saving 4) High Solidity 5) Refer Following Advantages for the Detail Features | 1) Bolt Asssembly,Fast Delivery Time, Easy Assemble &Move in Future 2) Medium Quantity Storage 3) Short Poject Period 4) High Solidity 5) Economical | 1) Cheap Cost 2) Small Size Storage 3) Fast Delivery 4) Easy Assembly and Move in Future |

| Optional Auxilliary Systems | 1) Dedust System 2) Level Indicator 3) Loading and Unloading System 4) Cement Block Break Device 5) Explosive-Proof Double Direction Pressure Balance Valve | 1) Dedust System 2) Level Indicator 3) Loading and Unloading System 4) Cement Block Break Device | 1) Dedust System 2) Level Indicator 3) Loading and Unloading System 4) Cement Block Break Device |

| TALK TO US, LET US WORK OUT YOUR INTEGRAL PLAN | ||

Application of Our Lipp Cement Silo

1- Can store bulk cement for cement production factory

2- Can store cement used for concrete batching plant

3- Can store cement used for block productine line

4- Can store other mineral powders, coal slag, coal ash, gypsum, coal, special construction materials, rare earth metals etc.

5- Used in hydro-power industry

6- Other special area.

Spiral Folded Lipp Cement Silo Advantages

1- With Max Assured Safety Consideration Leant from Our Over 3000 Units Silo Experience.

2- Spiral Folding, Max Sealing Performance, Can Have Fumigation System and Store Liquids

3- Connection Part is 5 Times the Thickness of Steel Plate, with Reinforcing Ribs and Wind Rings, Thus Assure Higher Strength and Solidity

4- Spiral Folding Silo is Integral Whole Body and with Longer Life Span to 25-40 Years

5- Fast Assembling and Easy Maintenance, the Project Time is Much Shorter than Bolt Assembly Silo

WHY OUR LIPP CEMENT SILO IS SUPER FOR YOU?

1- One of the Earliest Integral Solution Provider of Cement Silo Storage System

2- With the Most Reliable Project Design Technology Team

3- We Work All Efforts Out to Guarantee the All-round Safety of Your Project.

4- We Have the Biggest Cost Advantage and Supervision of Raw Materials Quality as We are Located at the Galvanized Steel Production Base.

5- With all over 3000 units silo projects under good operation till now

6- Have Strategical Cooperation with COFCO, YIHAI CHERRY China National Reserve etc. and Have Participated Several International Bank Projects.

Picture:

- Q:How come the Amish folk never get together on weekends and throw up a skyscraper?

- Adverse massing .

- Q:I'm just curious, are there any? If there are, what job classification?Thanks.

- Actually, STRATCOM is headquartered at Offutt Air Force Base in Nebraska.

- Q:Grain is pouring out of a silo at a constant rate of 4 m^3/min. As it falls, the grain forms a conical pile that has a radius twice its height. How fast is the radius increasing when the radius is 7 m?I am not getting the answer at the back of the book: the answer is 8/49pi m/min. Thanks

- haha, you're lucky I was on this for another questions, so u get a quick reply. ok, so the radius is 7, so the height is 3.5. Calculate the volume of the cone. pi*r^2 *height. 49*pi*3.5. You get 171.5 pi is the volume. Divide 171.5 by 7 (the radius) and you get how many minutes it takes for the radius to grow one meter. (6.125 minutes). But you want how fast the radius is growing. So simple 1/6.125= 8/49m/min. I'll leave the transfering of the unit pi to you. Goodluck!

- Q:How can we use social media company to support existing mediums and marketing channels?

- Create a Facebook Fanpage, and offer something for liking the page Use stumble to bookmark your website and specific pages or specials you want to promote Use social media as much as you can. There are tons of sites now, and it's free advertising! Social bookmarking not only gets your name seen, it also helps your seo.

- Q:Are Pakistan's nukes in some warehouse or are they in silos ready to fire?

- Given the tensions between Pakistan and India, it's a good bet that they are in silos. Probably unfueled, but for the most part ready to fire. Like ours. If you are going to have tactical nukes, they need to be ready to be used.

- Q:How to actually get IN the Treasure Room, not how to get the jiggy

- Get at least 25 notes then find Jamjars silo, he will teach you how to fire eggs. With your new moove go to treasure chamber building and shoot eggs into mouths of 6 snake statues to open the door.

- Q:Anybody heard about Silos being emptied?

- Yes. many have been turned into homes.

- Q:I would like to know how to make a silo for ginger beer. Any idea? A site to refer? Thanksearn 10 points!

- i did search but nothing found sorry

- Q:grain that can be stored in the silo?

- V = (d/2)?πh, where V is volume, d is diameter, π is 3.14, and h is height. V = (16ft / 2)? × 3.14 × 39 ft V = 64 ft? × 122.46 ft V = 7,837.4 ft? ===========

- Q:I need the Goodbye challenge

- district: you can fall down the well

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Germany Technology Cement Silo Cement Industry Equipment

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords