Geomembrane Pool liners by biggest lining factory in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

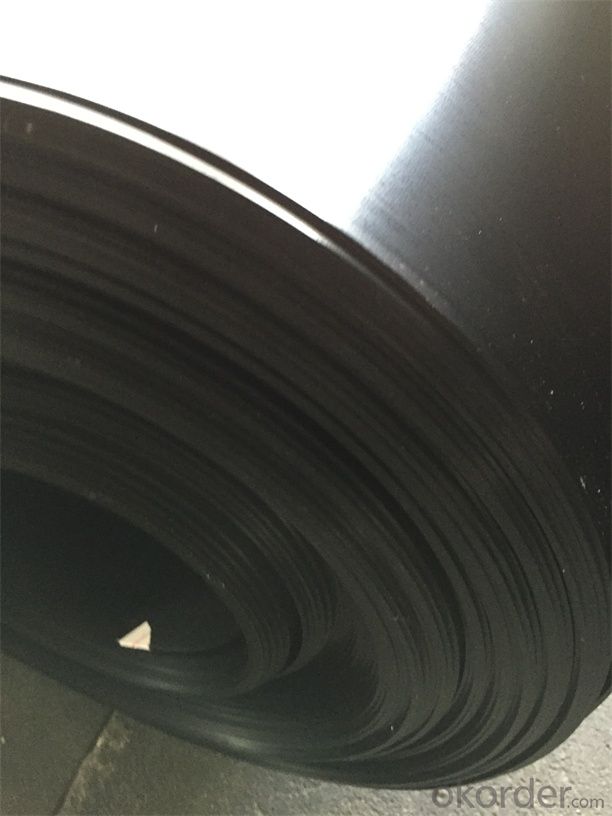

Specifications of Geomembrane

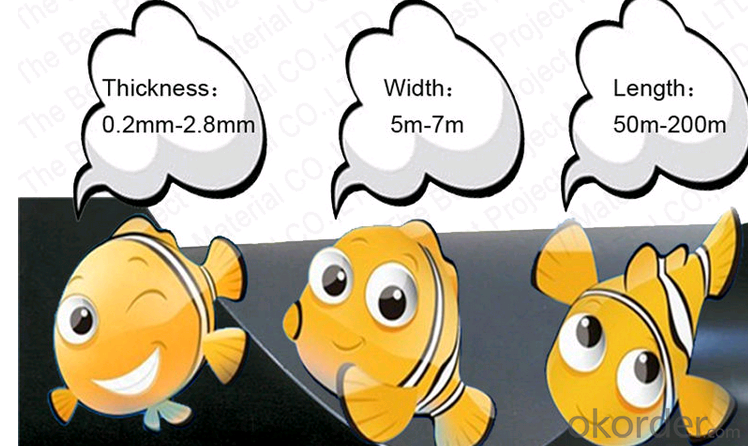

1) Thickness : 0.15mm - 4.0mm.

2) Width : Within 8 m (1m-8m).

3) Length : 50m-100m/roll (as request).

4) Material : HDPE,( LDPE, LLDPE, PVC, EVA ).

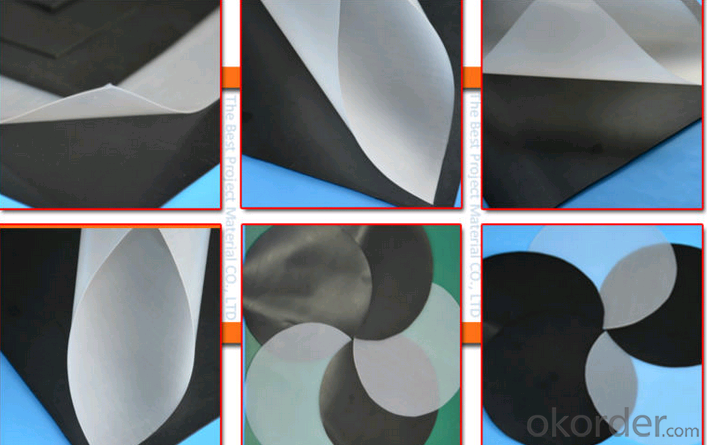

5) Color : Black , white , red , blue , or as required.

6) Optional surface : Textued(one or two side) or smooth surface.

7) The biggest geomembrane liner manufacturer/factory in China for many years .

Geomembrane specifications

1) Thickness : 0.15mm - 4.0mm.

2) Width : Within 8 m (1m-8m).

3) Length : 50m-100m/roll (as request).

4) Material : HDPE,( LDPE, LLDPE, PVC, EVA ).

5) Color : Black , white , red , blue , or as required.

6) Optional surface : Textued(one or two side) or smooth surface.

7) The biggest geomembrane liner manufacturer/factory in China for many years .

HDPE geomenbrane Features

Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

HDPE Geomembrane Applications

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

HDPE geomembrane technical index

No. | Item | Test Value | ||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 2.0 mm | 2.5 mm | 3.0mm | ||

1 | Minimum Density(g/cm³) | 0.939 | ||||||

2

| Tensile Property | |||||||

Strength at yield,N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | |

Strength at break ,N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | |

Elongation at yield,% | 12 | |||||||

Elongation at break,% | 700 | |||||||

3 | Tear Resistance N | 93 | 125 | 156 | 187 | 249 | 311 | 374 |

4 | Puncture Resistance N | 240 | 320 | 400 | 480 | 640 | 800 | 960 |

5 | Stress Crack Resistance, hrs | 300 | ||||||

6 | Carbon Black Content, % | 2.0-3.0 | ||||||

Carbon Black Dispersion | 1 or 2 | |||||||

7 | Standard OTI Min | 100 | ||||||

High Pressure OTI Min | 400 | |||||||

8 | Impact Cold Crack at -70°C | Pass | ||||||

9 | Water vapor permeability (gNaN/cm2 .s.Pa) | ≤1.0×10-13 | ||||||

10 | Dimensional Stability (%) | ±2 | ||||||

FAQ:

- Q1: Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

HDPE Geomembrane Price

- Q2: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

- Q3:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

- Q4:What is your delivery time?

A:Production time usually costs 2-20 days.

Gemembrane Show:

- Q:Geomembrane classification

- Seen from the naked eye, particulate is because the feed back material is added too much. Secondly, take samples of the material on site and sent to relevant national authorities to be tested, while adding too much back material will cause the HDPE membrane not reaching American standard index, indicating that the material is not very good, but one thing you can see, as well as some granular things, sand holes on the membrane, which is difficult to distinguish

- Q:What is the application of composite waterproofing geomembrane?

- composite geo-membrane: composite geomembrane, composite impermeable membrane)it's divided into one cloth one membrane and two cloths one membrane. pulling-resistance, tear-resistance, bursting and other high physic mechanics performance indicator, the products is high strength, and has good extensibility, large deformation modulus, acid and alkali resistance, errosion resistance, aging-resistance, seepage-proof and other characteristics.

- Q:Can geomembranes be used in stormwater management systems?

- Yes, geomembranes can be used in stormwater management systems. They are typically used to line stormwater detention ponds, tanks, or channels to prevent the infiltration of water into the surrounding soil. By containing stormwater within the geomembrane liner, it helps to prevent contamination of groundwater and control the flow of stormwater, allowing for proper treatment and management.

- Q:Which application fields is HDPE geomembrane chiefly suitable for?

- Environmental sanitation, sewage?disposal?plant and heap leaching pool: saltern crystallizing pond, settling pond. Polyethylene impermeable membrane is suitable for gardens, plastic straw mat membrane in saltern and impounding pond: 3. salt membrane, vertical core wall: It is suitable for subway, factory farming pools, impounding reservoir and roof garden; 8. High-density polyethylene geomembrane is suitable for petrochemical, twice lining and lining of shrimp pond. 2; 5: Such as refuse landfills, halogen pool cap, afforesting lawn for water and moisture resistance. Polyethylene geomembrane is suitable for mining industry and fishpond: Chemical plants and dissolved pools. Low-density polyethylene film is suitable for transport facilities, sea cucumber circle slope protection, etc. LDPE impermeable membrane is suitable for agriculture, seepage-proofing of ditch, power plant regulating reservoir, green roofs, storage?yard, industry, geomembrane solidification, sewage pipe anti-seepage. High density polyethylene impermeable membrane is suitable for salt industry, oil refineries, the pond bottom of golf course: reservoir: 6; 9. It is suitable for the proof seepage of drinking water pond and irrigation system; 10. LDPE impermeable membrane is suitable for water?conservancy project and seepage proofing for culvert: Artificial lake, chemical reaction pools, hospital solid wastes, underground constructions of buildings; 4: Intensification, seepage-proof of tailings bottom lining,etc: Such as seepage proofing for rivers, lakes, reservoirs and dams: Washing ponds. HDPE membrane is suitable for the seepage proofing aquaculture?industry, ashery, leaking?stoppage and oil tank: Road base reinforcement, slope protection, etc.; 7. HDPE impermeable membrane is widely used in municipal engineering, lining of settling pond, revetment, and watercourse. HDPE geomembrane is suitable for environmental protection.

- Q:Are geomembranes resistant to bacterial growth?

- Yes, geomembranes are typically resistant to bacterial growth due to their impermeable and non-porous nature, which makes it difficult for bacteria to attach and proliferate on their surfaces.

- Q:How to clean the keyboard cover?

- Some keyboard covers are made of silica?gel. The silica gel will be oxidized in the air. Meanwhile the surface of the notebook will dissipate heat, which accelerates the aging of the keyboard cover. When it becomes sticky and a lot of dust is attached to the surface of it, then the keyboard cover can be abandoned. As for cleaning the keyboard cover, you can just wet it with clean water and lay it on the clean and smooth surface to be naturally dried. (When dry the protective?film, you should not forget to clean the keyboard by using speical burnisher.)

- Q:What are the advantages of using geomembranes in water containment?

- There are several advantages of using geomembranes in water containment. Firstly, geomembranes provide a highly effective barrier against water seepage, preventing leakage and minimizing the loss of water. Secondly, geomembranes are durable and can withstand harsh environmental conditions, ensuring long-term protection and stability of the water containment system. Additionally, geomembranes are flexible and can be easily installed over irregular surfaces, reducing the need for extensive site preparation. Moreover, geomembranes are resistant to chemicals and UV radiation, making them suitable for various water containment applications such as reservoirs, ponds, and landfills. Finally, geomembranes are cost-effective compared to traditional methods of water containment, offering a reliable and efficient solution for managing water resources.

- Q:Should geotextile be laid under the geomembrane in the fish or shrimp ponds?

- It is unnecessary. You are wasting your money if you buy it. However, it still depends on the brand of the geomembrane you bought.

- Q:is geomembrane used in waste transfer station?

- 1, polyethylene geomembrane is sanitary and good for environmental protection. Refuse landfills, sewage treatment plants, power plants regulating reservoir, solid industrial and hospital waste etc. 2 polyethylene geomembrane can be used in water conservancy; It is used for anti-seepage, leaking stoppage, reinforcement of dams, reservoirs in rivers and lakes, anti-seepage of drainage, vertical walls, slope protection 3,polyethylene geomembrane can be used in aquaculture. Intensification and industrialization of culture pools, fish ponds, prawn ponds, revetment in sea cucumber area, slope protection, etc. 4. polyethylene geomembrane can be used in gardens. Artificial lake, riverway, reservoir, golf course pond bottom, slope protection, green lawn dampproof. 5. polyethylene geomembrane can be used in petrochemical industry. Chemical plants, oil refineries, oil storage tank anti-seepage, chemical reaction tank, sedimentation tank lining, the second lining 6, polyethylene geomembrane can be used in mining industry. Washing pool, heap leaching pool, ashery, dissolving tanks, sedimentation tanks, storage yard, bottom lining of tailings anti-seepage etc 7. polyethylene geomembrane can be used in transport facilities: Roadbed reinforcement, culverts anti-seepage 8. polyethylene geomembrane can be used in agriculture: Reservoirs, drinking water tanks, water storage pond, irrigation systems anti-seepage 9. polyethylene geomembrane can be used in municipal engineering. Iron, building engineering, planted roofs, roof garden anti-seepage, sewage pipe 10, polyethylene geomembrane can be used insalt industry. saltworks crystallization pool,salt film.

- Q:What is the role of geomembranes in landfill capping systems?

- The role of geomembranes in landfill capping systems is to act as a barrier, preventing the migration of leachate and gases from the landfill into the surrounding environment. They are an essential component in preventing contamination of groundwater and soil, as well as controlling odors and reducing the overall environmental impact of landfills.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Geomembrane Pool liners by biggest lining factory in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords