GATE VALVE NON-RISING STEM METAL SEATED DUCTILE IRON JIS

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | China | Model Number: | JIS 10K | Brand Name: | CMAX |

| Shape: | Round | Special Use: | Water | Standard: | JIS, AISI, ASTM, GB, DIN, EN, Other |

| Application: | all sectors | Dimensions: | 40mm to 600 mm | Certification: | ISO/ CE |

| Structure: | Gate | Pressure: | Medium Pressure | Temperature of Media: | Normal Temperature |

Packaging & Delivery

| Packaging Details: | STANDARD/EXPORT PACKING/AS PER CLENTS REQUIRMENT |

| Delivery Detail: | 3-4 WEEKS /AS PER CLIENTS REQUIRMENT |

Specifications

Cast Iron JIS Non-Rising Stem Gate Valve

Certificate:ISO9001,ISO14001,CE,API,KS,GOST

Size from DN40-DN600

Cast Iron JIS-10K Rising Stem Gate Valve

Certificate:ISO9001,ISO14001,CE,API,KS,GOST

Size from DN40-DN600

Face to Face:JIS-10K

Flange:JIS-B2212

Valve Body,Bonnet:Cast Iron

Disc:Cast Iron

Seats:Brass

Stem:SS410

Hand Wheel:Cast Iron

Nominal Pressure:10K

Strength Testing:2.1Mpa

Seats Testing:1.6Mpa

1.Inspection:Foundry in-house; 100% Water Pressure Test ;Third Party inspection available upon request ..

2.Packing: As per the customer requirement .

3.Delivery Date:30 days ; According to the quantity .

4.Payment: 30% by T/T in advance, the balance before Shipping .L/C.D/P.

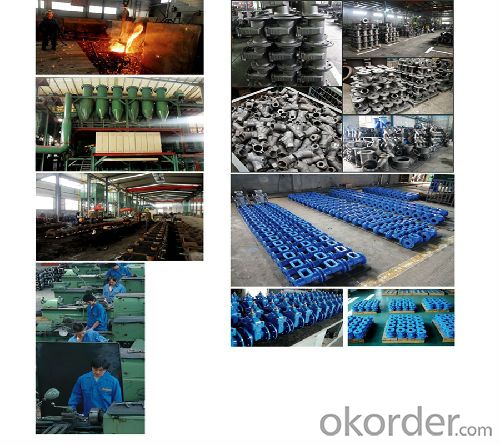

1. 10 years Industry and export experience

2. Extensive product range with good quality

3. Professional laboratory ,research and development team

4. Strictly test and quality control

5. Timely delivery and good after-sale service

6. Produce as per customer requirement

Welcome to contact us !

- Q:Gate valve DN65 what does that mean?

- Nominal diameter 65 gate valve.This depends on the material of your valve, it is new material, it is to use the outer diameter to do the standard, specifications with 63.75, and so on, because the new material is welded or coated with glue connection. So use the outside diameter as the standard, or the gap will appear.There is also the metal standard, according to the nominal diameter, or flange connection flange and skein skein are industry specifications.When it comes to the end, it must be between the pipe and fittings must be connected.

- Q:Which is the most expensive, check valve and gate valve?

- In the case of DN50 Z15T-16 DN50: screw valve 46.200 thread copper bar gate valve Z15T-16 DN50 52 Z45F-16 DN50 97 flange valve flange valve rod Z44T-10 DN50 169 Z45T-116 DN50 flange valve dark bar 173 thread swing check valves DN50 52.090 thread straight type check valve DN50 57.280 flange screw check H44T DN50 129 flange valve lift check valve H41T-16 DN50 124

- Q:Why does the fire hydrant box in the air defense area need to be added with gate valves?

- Code for design of basement for civil air defence GB50038The installation and installation of the protective valve on the water supply line of the 6.2.13 air defense basement shall comply with the following requirements:OneWhen the water supply pipe from the entrance into, should be set up in the inner protective sealing door;

- Q:What is the standard for ductile iron gate valve set?

- Fujian - mark light - valve for you to answer:Whether it is the next shot or dark bar, directly flanged valves can be installed, usually apply eighth copies, if the industrial pipeline is apply sixth copies, sixth copies to apply separate sets of flanges and bolts (bolts independent fee).

- Q:What do you mean by gate valve type RVHX-0150-10 and Z45X-16Q?

- Z45x-16q, Z means gate valve, 4 means flange connection, 5 refers to dark rod gate valve, X means rubber seal, 16 refers to nominal pressure 1.6MpaRVHX means manual gate valve, 150 refers to the caliber of DN150, and 10 indicates nominal pressure of 1.0MPa

- Q:What's the difference between a soft seal gate valve and a hard sealed gate valve?

- Soft sealing gate valve is rubber seal, F sealed, hard sealing gate valve is the medium of particles.

- Q:What are the differences between the gate valve and the cut-off valve?

- The operating principle is different. The stop valve is an upward stem type, and the handwheel rotates and rises with the stem. Valve is hand wheel rotation, stem upward movement. Flow is not the same, the gate valve requires full open, the cut-off valve is not the same. The gate valve has no inlet and outlet direction requirements, and the cut-off valve has the required inlet and outletAt the same time, usually with the cut-off valve instead of gate valve, but the valve can also be used instead of cut-off valve. Valve sealing performance better, but the size is generally not large, the size of the gate valve can be done great.The main difference between them lies in:1, different structure, gate valve structure is more complex than the height, larger size, from the appearance point of view than the cut-off gate valve is short and high, especially the gate height space needs a higher open bar, the selection in the installation space under the condition of limited attention to.2, sealing surface, valve in the opening and closing valve and the valve seat surface always contact and friction between the sealing surface, and thus easy to wear, especially in close off the valve when the valve before and after the great pressure, sealing surface wear is more serious. And the valve once the valve is in open condition, it's seat and disc sealing surface between, not in contact,

- Q:What are the meaning of the cast rigid gate valves z41h-16c?

- According to the provisions of the JB/T 308-2004 valve type programming method:Z== gate valve4== flange connection1== rigid single gateH== sealing surface material: Cr13 stainless steel16== pressure rating: 1.6MPaC== body material: carbon steel

- Q:What does the gate valve SZ45X-1.0 stand for?

- A modelModel SZ45T-1.0, especially in DN100 ~ DN300 piping, soft sealing gate valve shall be used

- Q:Why the valve can only be fully open and fully closed valve can adjust the flow?

- Valve, if adjusted, it is easy to wash the sealing surface, resulting in sealing surface damage.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GATE VALVE NON-RISING STEM METAL SEATED DUCTILE IRON JIS

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords