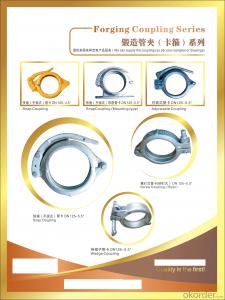

forging coupling of the concrete pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Concrete Pump Coupling

SCHWING, SANY, ZOOMLION SUPPLIER

PIPE CLAMP

BOLT COUPLING

Concrete Pump Coupling- snap coupling

1. We are a professional manufacturer of concrete pump couplings in China. Our products include delivery pipes, elbows, reducers, couplings, rubber hoses, cleaning balls and so on.

2. Our products are Top quality in china which can be used on SCHWING, PM, KYOKUTO, SANY, ZOOMLION and have been recognized by them.

3. OEM available from us.

- Q:I live in an apartment that has electrical smoke detectors hard wired into all the units and have lived here for about 4 yrs and recently have noticed that my smoke detectors keep going off for no rsn whatsoever, they are not battery operated they just go off the other day went off at 2 am scared me to death! What could it be im clueless help! so far i have disconnected them which is not safe but i dont want to keep getting scared, also i have dusted them and checked for spiders they are ok just going off for no rsn.

- */pdf/533.pdf *use CAM/CAM simulation.

- Q:is it water. or something else

- a fire place electric blanket clothes covers coats socks a wood burning stove the oven

- Q:cant remove front rotors tried to get off tapping a hammer on backside no luck

- Press cntr,alt,delete. Brings up the process manager, goto,run, Type explore.exe.

- Q:Direct connections as shown in Fig.G1/4.If you do not use the card sleeve, can the thread of the card sleeve be directly connected with the internal thread of the G1/4?

- InequableThe card sleeve is divided into two types: a single card sleeve and a double clamp sleeveThe sleeve end thread single card is generally metric thread, 6mm or 1/4 "card sleeve thread is M12*1.5."G1/4 is pipe thread with fixed thread, outer diameter and pitchDouble card for UNF fine thread (also have metric teeth, but already very little), and G1/4 internal thread is even more not matching

- Q:do they remove the tooth? will he be able to drive back? Will he be able to talk immediately after it? thanks

- Yes, I have the problem where I get up, turn off the alarm, and go back to sleep, thus being late.. LOL. What you should do is get multiple alarm clocks and set them to go off at the same time. That way you have to force yourself to get up and shut off all the alarms. By the time you're done you will be out of that haze.

- Q:what is the lifespan of nitrile rubber?

- All of the ideas above are right on the mark. Soldering for plumbing requires: - tightly aligned parts no out-of-round pipes or fittings, and burrs should be removed. I use a pipe cut-off tool rather than a saw to cut pipe. - very clean surfaces (inside the coupling/fitting and outside the pipe) - flux to remove any residual tarnish (oxide) and to allow the solder to flow - plenty of heat (including no water anywhere near the joint, which will keep it cool because you end up boiling water. The bread idea works.) One thing you should check is that you are using the right gas torch to match your solder type. If you use eutectic tin-lead solder (63:37 ratio), then you can use an ordinary propane gas torch. (This solder alloy is no longer permited for drinking water plumbing, though.) If you are using a lead-free solder, you should switch to a MAPP gas torch, which will provide a hotter flame. If by chance you are using a 2% silver-bearing solder, then a MAPP torch is mandatory because the solder melting point is much higher than lead-free. The solder is also very strong. Apply a bit of flux to the cold parts before heating, then heat all the fittings and pipe uniformly to melt the flux. Remove the flame then apply more flux till it flows well around the solder joint. Apply the flame again and test the temperature by touching your solder to the opposite side of the flame. If it flows, then finish applying solder around the joint and keep the flame 180 degrees on the opposite side the molten solder will flow to the hotter side.

- Q:Brother, recently in water fire fighting system, the original use of galvanized steel +SUS316 joints and connections, then proposed to ordinary customers galvanized and connector joint, but in the course of the trial, we found that the common galvanized joint or SUS304 joint effect is not good, will Water Leakage, after the change of 316 joint basically there is no Water Leakage phenomenon, I would like to ask, if only SUS316,The PS: test pressure is 10 kg and the pressure is 1 hours

- . Because the flame retardant material is added to the coating material, the temperature resistance of the product is improved compared with other similar products. Therefore, when the ambient temperature rises rapidly, it will not affect the use. Internal and external fire tubes are much better than galvanized pipes in service life and performance.

- Q:i have a white pvc front door which has brass handle and letterbox which are both beginning to look very tatty. i want to change them to white. i know the letterbox is just a easy straight swap but what about the handle. would i need to change the lock aswell?

- Note:. ..II.. .||G..G.||.G .||E/F..E/F..||.E/F.. A-B-C-HDDHDDDHI .||||. .||||. ..II.. Note, disregard the ., they were supposed to be spaces, but Yahoo kept dropping the formatting. Cut, prime, and glue everything together as I described above. It'll be obvious once you get the parts in front of you. Good luck!

- Q:What is the size of the PVC pipe joint?

- In practical applications, stabilizers must be added to improve the stability of the heat and light. PVC is very hard and can only be dissolved in a few solvents such as cyclohexanone, two dichloroethane and tetrahydrofuran. It is stable for organic and inorganic acids, alkalis and salts, and the chemical stability decreases with the increase of the use temperature.

- Q:Can they also be water proof? Because it is a lake of fire we're talking about

- flat pack generally is referring to the way many materials are packaged for ease of shipping and resale including all types of hardware :furniture which is shipped unassembled and boxed flat for easy shipping and requires assembly by customer are considered flat packs.. :nuts,bolts,screws, misc pipe fittings, and many other items are prepacked in uniform size packages to be easily displayed are also flat packs. .

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

forging coupling of the concrete pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products