Food Processing Conveyor Belt Food Grade Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

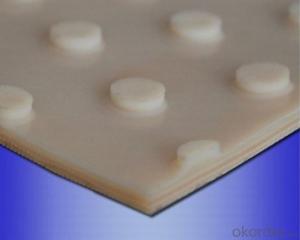

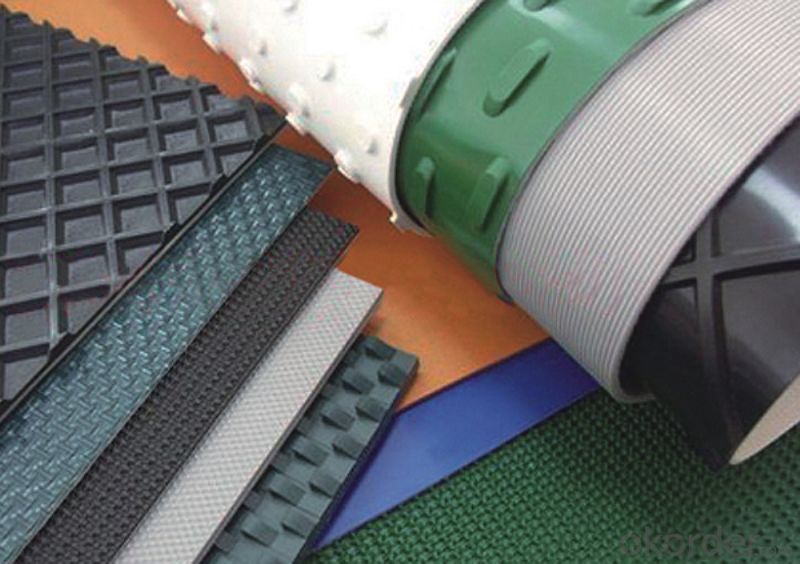

Food Processing Conveyor Belt

Food Processing Conveyor Belt Introduction

Food processing conveyor belt choose high quality high strength polyester fabric are the core, coated with PU or PVC as loading surface. With advantages of good flexibility, material environmental friendly, light duty, high tensile strength, anti oil, easy learning, our food processing conveyor belt meet EU and USA market requirements.

Food Processing Conveyor Belt Application

Food processing conveyor belt is widely used in food industry, such as vegetables, snack food, beer, sea food, etc.

Food Processing Conveyor Belt Advantage

Food processing conveyor belt is made of harmless material, no toxicity, no smell, anti-oil, easy cleaning, high tensile strength, good flexibility, light weight, solid and durable.

Food Processing Conveyor Belt Specifications

Total thickness(mm) 0.8~5.0 | Top coating hardness( Shore A) 55~92 |

Total weight(kg/m2) 0.9~5.4 | Belt tension 1% elongation(N/mm) 5~ 30 |

Minimum production width(mm) 15~180 | Working temperature range(℃) -20/+90 |

Type of support R=expansion cylinder, S=flat, T=groove shape | Max production width(mm) 3000 |

Lateral stability Yes | Food grade Yes |

Low noise | Fire resistance |

Surface antis tatic |

Food Processing Conveyor Belt Photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

Quality is the first priority, we have strict quality control system.

1) All raw material we used are environmental freindly

2) Quality Control Department specially responsible for quality checking in each process. We make testing on incoming raw material and finished products. Your third party testing is also welcomed.

3) Skillful workers care every details in handling the producing and packing processes.

Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q:Do olive nets require any specific training for proper installation and removal?

- Yes, olive nets do require some specific training for proper installation and removal. It is important to learn the correct techniques to ensure the nets are installed securely, covering the olive trees effectively, and minimizing any damage to the branches or fruits. Similarly, proper training is necessary for removing the nets without causing any harm to the trees or disturbing the olives. Training can help individuals understand the best practices, safety precautions, and equipment required for efficient installation and removal of olive nets.

- Q:Can olive nets be used in regions with sandy or rocky soils?

- Yes, olive nets can be used in regions with sandy or rocky soils. These nets are designed to protect the olives from falling off the trees during harvesting. They can be spread over the ground beneath the olive trees, regardless of the soil type, to collect the harvested olives and prevent them from getting damaged.

- Q:How do olive nets impact the growth and development of olive trees?

- Olive nets can have a positive impact on the growth and development of olive trees. These nets provide protection from harsh weather conditions, pests, and birds, allowing the trees to thrive in a controlled environment. Additionally, the nets help in maintaining a consistent moisture level in the soil, preventing excessive water loss and promoting healthy root development. Overall, olive nets contribute to higher yield and improved quality of olives, resulting in enhanced growth and development of olive trees.

- Q:What plastic sunscreen?

- Plastic products are exposed to sunlight or strong fluorescence, causing the aging of plastics due to the ability to absorb ultraviolet light. Adding light stabilizers can reduce the effect of UV light on plastics. Mainly used in PO products, mostly for PE, a few for PP, and PVC, ABS, PS, and so on.

- Q:Can olive nets be used for olive trees in regions with high bird populations?

- Yes, olive nets can be used for olive trees in regions with high bird populations. These nets are specifically designed to protect the olive fruit from being damaged or eaten by birds. By covering the trees with these nets, farmers can effectively deter birds and ensure a higher yield of olives.

- Q:Can olive nets be used for olive tree pruning purposes?

- No, olive nets are not typically used for olive tree pruning purposes. Pruning involves trimming and shaping the tree's branches and foliage, while olive nets are primarily used for harvesting olives by catching the ripe fruits as they fall off the tree.

- Q:Can olive nets be used in olive groves with limited access for machinery?

- Yes, olive nets can be used in olive groves with limited access for machinery. Olive nets are lightweight and easy to install manually, making them suitable for groves where machinery cannot easily navigate. These nets can be manually spread across the trees to collect falling olives during harvest, providing an efficient solution for groves with limited machinery access.

- Q:Can olive nets be used in areas with high salinity in the soil?

- Yes, olive nets can be used in areas with high salinity in the soil. These nets are primarily used to protect olive trees from pests and birds, and they do not directly interact with the soil. Therefore, the salinity level in the soil should not affect the functionality or effectiveness of the olive nets.

- Q:What is the role of calcium carbonate in plastics?

- Improve the hardness and rigidity of plastic productsIn plastics, especially in soft PVC, the hardness increases with the amount of calcium carbonate, and the elongation decreases with the increase of hardness. Particle size, oil absorption value of calcium carbonate, hardness growth rate. Conversely, the particle crude oil absorption value of small calcium carbonate, plastic hardness growth rate is small. In soft PVC, calcium carbonate (light) is the next to the lowest hardness growth rate of heavy calcium carbonate.

- Q:Can olive nets be used in olive groves with limited space for storage?

- Yes, olive nets can be used in olive groves with limited space for storage. Olive nets are lightweight and can be easily folded and stored in small spaces when not in use. They are designed to be compact and convenient for storage, making them suitable for olive groves with limited space.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Food Processing Conveyor Belt Food Grade Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords