Fireclay Insulation Refractory Brick for Furnace Price Of Refractory Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Fireclay Insulation Refractory Brick for Furnace Price Of Refractory Brick is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of Fireclay Insulation Refractory Brick for Furnace Price Of Refractory Brick are made of selected high alumina bauxite, kaolin clay, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature

Product Applications:

1. Furances of glass,coke oven,electric and so on

2.Furnaces of metallurgy industry, heat treatment furnace

3. Furnaces of chemical industry and construction industry.

Main Product Features:

1. Low porosity,High bulk density.

2. High Cold Crushing strength.

3. High refractoriness under load.

Product Specifications:

1.With 55% Al2O3 min;

2. Refractoriness: 1750C min;

3.For steelmaking furnaces;

4.ISO 9001 Certificate;

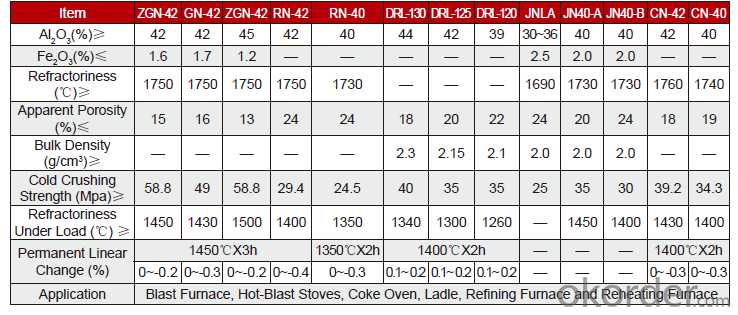

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q:does Kyrgyzstan have the refractory brick to build tunnel kiln, whose specifications are 390,235,11, 240,120,60.

- Domestic standard brick has no brick in this specification. only can be customised. Otherwise only have 230 * 65 * 114.

- Q:What is the use of refractory bricks

- Refractory bricks are mostly used as furnace lining in high temperature industry. Such as the iron and steel industry blast furnace, hot blast furnace, converter; colored reverberatory furnace

- Q:Is fireclay brick acidproof? Does clay brick anti corrosion when it's used to build chimney lining?

- Refractory bricks anti acid and alkali after high-temperature calcination, and anti-corrosion won't be a problem

- Q:MU10 what are the non clay solid bricks?

- Clay solid brick with clay and is needed by adding admixture as raw materials, solid bricks by water mixing, molding, high temperature calcination made, mainly used for masonry bearing and non bearing wall, wall materials is a kind of widely used.

- Q:what type of refractory bricks does TZ-3 stands for ?

- 65mm high, 230mm long, 114mm wide is the national standard T-3 refractory brick

- Q:What is the life of an old fashioned refractory brick kiln transformed into a flat topped tunnel kiln? what material should be used to transform the old fashioned refractory bricks vault kiln to flat tunnel kiln, and how long is the service life?

- use castable refractory

- Q:What bricks are used for constructting refractory bricks tunnel kiln what is the material of each burning zone brick

- To reduce the cost from a professional point of view, you should have the construction team to set up the specific solution for you, be sure to keep in mind not to save blindly, the best is to use refractory brick

- Q:What are the reasons for the production of waste in the formation of fireclay bricks?

- The reasons for the production of waste when form fireclay bricks: Tile size is unqualified. This is due to the mold installation is not firm, the template transfers when molding; if the amount of material being added fluctuates largely, also can cause the body size changing. Ji Yangon Chi lie charge generation layer containing decyl poke pull and crack. The molding operation does not according to the principle of the light first and the thick later. At the initial pressure, the air doesn't releases, which causes the elastic aftereffect by repressing. Too much mud water, uneven mixture and inequal template all can make the body produce layer crack or crack. Twist. The template is used for too long, the template deforms, so raw brick deforms, the amount of water is too large, brick naturally deforms, causing the body twist. Miss edge and angle. Because of poor plasticity of mud, particles segregate, feeding back corner is not real, the body will appear side missing and angle modulation phenomenon. Bias voltage. Due to the deflection of the die head or the uneveness of mold bottom. Loose。 Due to insufficient feeding amount or insufficient pressure times.

- Q:What are 85 bricks, 95 bricks and standard bricks? What are the specifications?

- Clay to clay (including shale, coal gangue powder) as the main raw material, through mud processing, molding, drying and roasting and.

- Q:What are the specifications of clay brick and cement brick construction?

- 95 bricks are standard bricks. Specification: 95 240*115*53mm85: 216*105*43mm: brick brick brick, artificial small bulk building, divided brick (clay brick) and non sintered brick (sand lime brick, fly ash brick etc.), commonly known as brick.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fireclay Insulation Refractory Brick for Furnace Price Of Refractory Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords