Fireclay Bricks for Hot Blast Stove

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Fireclay Bricks for Hot Blast Stove

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | superfine burned flint clay/high quality combined clay/ additives |

| Brand Name: |

Packaging & Delivery

| Packaging Details: | manner of packing:Fumigation wooden pallets+paper angle bead+PET strap+stretch film. Wooden pallet size:930*930mm load weight of each pallet:1.5-2.0 tons |

| Delivery Detail: | within 30 days after signing the contract |

Specifications

1.Lower creep

2.To maintain the service life of the kiln

![]()

Such product selected superfine burned flint clay and high quality combined clay as main raw materials, and also selected materials which not easy to shrink and react with minerals at high temperature as additive . After high pressure shaping and high temperature firing , we can get this product.So the product has high strength,high density and low creep rate,and it can better applied to the hot blast furnace,glass furnace and chemical furnaces,etc.

![]()

| Product Item | XX | X | N43 | N42 | N41 | DRN-125 | DRN-120 | DRN-115 | DRN-110 |

| Fe2O3 % | ≥42 | ≥39 | ≥40 | ≥40 | ≥42 | ≥45 | ≥42 | ≥40 | ≥36 |

| Refractoriness °C | ≥1750 | ≥1730 | ≥1730 | ≥1730 | ≥1750 | ||||

| Apparent Porosity % | ≤20 | ≤22 | ≤24 | ≤24 | ≤24 | ≤22(24) | ≤22(24) | ≤22(24) | ≤22(24) |

| Bulk density g/cm3 | ≥2.15 | ≥2.10 | ≥2.10 | ≥2.15 | ≥2.25 | ≥2.25 | ≥2.15 | ≥2.10 | ≥2.10 |

| Cold crushing strength Mpa | ≥35 | ≥35 | ≥30 | ≥30 | ≥30 | ≥40 | ≥35 | ≥30 | ≥25 |

| Refractoriness under load KD,°C | ≥1450 | ≥1400 | ≥1400 | ≥1450 | ≥1450 | ||||

| Permanent Linear Change % | 1400°C×4h ±0.2 | 1400°C×4h ±0.2 | 1300°C×2h ±0.2 | 1350°C×2h ±0.2 | 1400°C×2h ±0.2 | 1400°C×2h -0.4~0.1 | 1350°C×2h -0.4~0.1 | 1300°C×2h -0.5~0.1 | 1300°C×2h -0.5~0.1 |

| creep rate(0.2Mpa*50h)% | 1250°C *(20-50) ≤0.2 | 1200°C *(20-50) ≤0.2 | 1150°C ≤0.8 | 1200°C ≤0.8 | 1250°C ≤0.8 | 1250°C ≤0.8 | 1200°C ≤0.8 | 1150°C ≤0.8 | 1100°C ≤0.8 |

| Application | Regenerative chamber walls and the grid of hot air stove, and the combustion chamber and air chamber of mixed contact tube and various burner brick | ||||||||

![]()

It is widely used in hot blast furnace,glass furnace and chemical furnaces,etc.

![]()

1.Strong professional:

A:The manager of our company has 50 years working experience in refractory product, technology and trading. He has professional function on a various refractory’ s production materials, process control, quality supervision and package delivery.

B: .Company staff are very familiar with refractory and professional knowledge is very good .

C:Company staff are all college culture level.

2. .Annual supply:

Our company has a dozen cooperative production factories which are better in productive technology and quality management. All the factories has passed ISO9001 quality management system certification. And the annual supply of dense shaped and unshaped refractory product is 100,000-200,000 tons.

3. Annual exports:

Now we have exported more than ten countries , such as Asia ,Europe and South America.The average annual export amount is 10 million Yuan , about $1.6 million.

4. Production equipment:

Production and testing equipments are new, complete and automated or semi- automated. Such modern facilities and equipments have provided the fine technical guarantee for the production and testing.

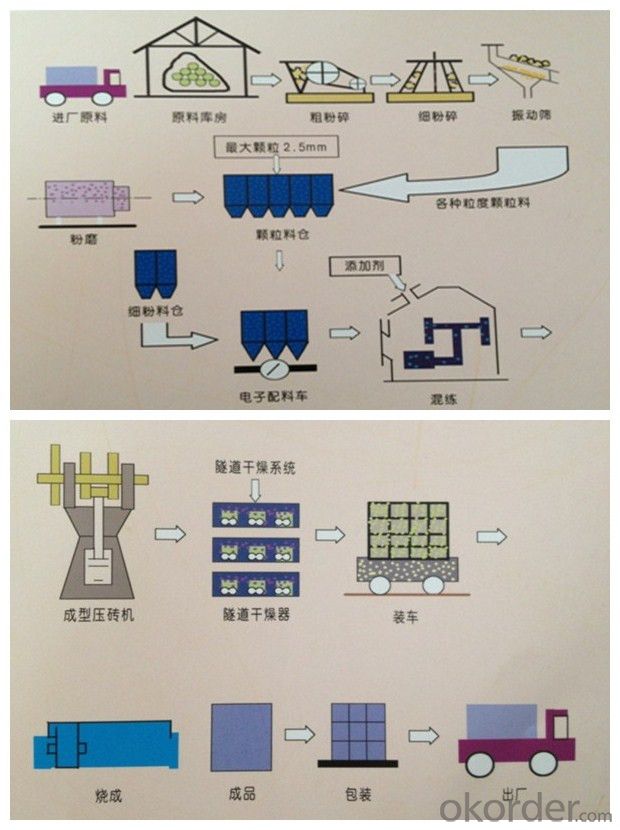

5. Process flowdiagram:

6. Order processing:

After the contract is signed, the relevant responsible person tracked production progress, product quality and product packing aperiodically. During the term of contract sent on time with quantity and quality guaranteed.

Why choose us?

1.Competitive price and stable quality to be offered Our refractory materials has export to South America,Australia,Malaysia,UK,etc for many country.

2.Our company provide customer with satisfactory products and services

3.Maybe our price is not the lowest, but our Brick quality is the most trusted

4.we are the real maker and supplier in China, not the middleman.

If you have any questions, we will try our best to satisfy your requirements

Welcome to visit our factory.

- Q:how much is the content of the high alumina of refractory brick?

- linear?change?on?reheating is small and Slag resistance is good, matte smelting, good thermal shock resistance used refractory materials should be resistant to high temperature: In front of the furnace, the temperature can reach 1800, copper blowing. The maximum temperature in the smelting furnace area is on the top, pyro-refining and electrorefining, magnesia chrome brick, magnesia chrome castable, magnesia alumina brick. The commonly used refractory materials is direct-bonded?magnesia-chrome?bricks, which has large volume density. manufacturing technique of copper smelting consists of five parts, Clay brick

- Q:when to replace the worn refractory bricks in rotary?kiln?

- Wear out at least 23.

- Q:Does circulating fluidized bed boiler's furnace wall use refractory to have thermal insulation?

- Heat insulation cotton is laid behind refractory brick.

- Q:How to make refractory bricks? ? ?

- Can knock, use angle grinder to slowly cut off the glaze layer outside the refractory brick, and then use hand to gently tap, to compare the complete China to do the work of the destruction of the situation

- Q:Will the heat be taken away by the refractory brick

- The heat will be taken away by the refractory bricks.

- Q:what kind of refractory brick is suitable for 1300 degrees converter?

- magnesia-carbon brick, you can also use MgO-Al2O3 castable, it is good too.

- Q:do the used refractory bricks pollute the environment?

- the main pollution of refractory brick is coal gas pollution in the process of burning , it can be recycled to produce aggregate, waste brick has no pollution.

- Q:How many pieces of porous brick is equal to one ton?

- Refractory bricks are generally classified into two types, that is, shapeless refractory materials and shaped refractory materials. Shapeless refractory material: Also known as castable refractory, is hybrid power material composed of a variety of aggregate or a kind of aggregate and one or more kinds of the mixture of adhesive particles, it should be used evenly mixed with one or more kinds of the liquid, which has strong liquidity. Shaped refractory material: The general making of firebrick, there are standard rules for the shape, can also temporarily process according to need of building and cutting. The following are the specifications. fireclay bricks 230*114*65 each block 3.0 - 3.6 kg; special-shaped fireclay brick 230*65/55*114 each block 2.8 - 3.3 kg; the reason for the weight's ranges is that because the quality is different, in general, heavy density, good quality!

- Q:When the coal-fired steam boiler is built, it is necessary to build a common red brick between the refractory bricks. May I ask what is the requirement for this common red brick?

- unnecessary

- Q:What are the specifications of clay brick and cement brick construction?

- Chinese in the spring and Autumn period has created a square and brick, Qin and Han Dynasties brick technology and production scale, quality and variety have significant development, known as "Qin Zhuanhan tile".

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fireclay Bricks for Hot Blast Stove

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords