Fireclay Brick for Furnace Price of Refractory Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fireclay Brick for Furnace Price of Refractory Brick is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of Fireclay Brick for Furnace Price of Refractory Bricks are made of selected high alumina bauxite, kaolin clay, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature

Product Applications:

1. Furances of glass,coke oven,electric and so on

2.Furnaces of metallurgy industry, heat treatment furnace

3. Furnaces of chemical industry and construction industry.

4. Furnace of incineration of garbage, recirculating fluidized bed furnace

5. Standard sizing: 230 x 114 x 65 or 75 or 25 mm others up to the client

Main Product Features:

1. Low porosity,High bulk density.

2. High Cold Crushing strength.

3. High refractoriness under load.

4. High mechanical strength.

5. Good resistance to erosion.

Product Specifications:

1.With 55% Al2O3 min;

2. Refractoriness: 1750C min;

3.For steelmaking furnaces;

4.ISO 9001 Certificate;

5.Custom shape;

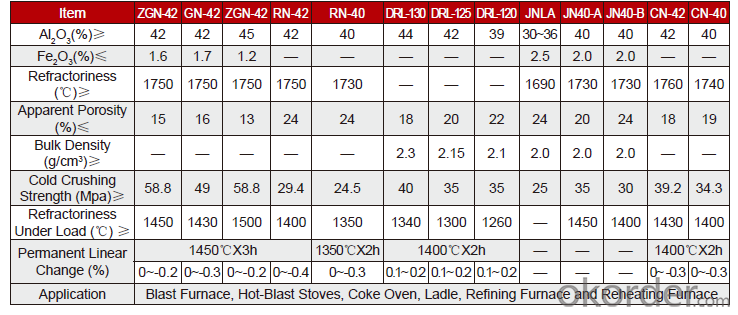

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q:What are the hazards of solid clay bricks?

- The prohibition or restriction of high energy solid clay brick production, the development of low energy consumption, thermal insulation of new wall materials, insulation performance is good, not only can save energy in production, but also can make the function of the building can be effectively improved, reducing the energy consumption in buildings in use.

- Q:does the furnace wall use refractory bricks to keep the heat? Or use the insulation material to keep heat ?

- The furnace arch and the furnace wall are all refractory bricks, and the refractory brick is a kind of thermal insulation material!

- Q:What is the best color of refractory brick

- Date red is better.

- Q:does the electric kiln burner need to be sealed?

- seal when open the kiln, and observe the temperature, when the temperature reaches a point, you can move the firebrick away, and continue observing the temperature to decide whether to seal it or not, but do not seal it completely, repeat the procudure until reach the sinter point or skill requirement.

- Q:Where the refractory bricks rider bricks that are used for building arch and vault should be put?

- Arch and vault shall be built simultaneously from both sides of the arch of the foot to the center of symmetry, when masonry, inverting concentric reducer of arch brick is prohibited; the lock should be driven into the brick arch from the side, if the last rider brick can't be driven from the side, you can process the first 1-2 brick to make the size of the lock and the lock buckle equal, and then drive suitable rider brick from top, and use steel plate to jam-pack the side; dismantling arch tire must be performed after all rider bricks are driven and lock brick arch foot ditch masonry is completed and the final tightening nut for skeleton retractor rear.

- Q:Should kiln be warmed before the ignition of the new furnace?

- If you don't have to heat up the furnace. The new furnace must be heated up, and the temperature should be increased according to the heating-up furnace curve, so the current situation you meet is appeared

- Q:What raw materials are used for refractory bricks

- Phenolic resin, clay, powder and other materials, nitride materail, boron carbide, silicon carbide, silica raw material three, soil: fluorite, magnesia-alumina spinel Aluminum soil, calcium aluminate cement, corundum, andalusite, chlorite, silica solution, which is mainly divided into six categories, sillimanite, vermiculite refractory bricks raw material composition of refractory brick, there are many raw material kinds of refractory bricks, mullite, mine: Soil, Sialon, forsterite, pyrophyllite: Metal aluminium powder, ore, stone: Pottery, zircon sand, quinidine sulfate, dolomite, kaolin: The fifth raw material of chrome ore, sodium silicate, diatomaceous earth is the second raw material: Asphalt, sand, shale ceramisite. One of the raw materials, stone powder, the fourth raw material is magnesite, the sixth raw material is silicon metal powder refractory bricks, sand, kyanite, silica powder, aluminium oxide, aluminum sol, quartz sand, perlite, cenosphere, graphite

- Q:Whether the cement kiln refractory bricks belong to hazardous waste or not?

- No, there is no harmful gas produced, and it will not pollute the ground.

- Q:What is the difference between the refractory bricks, hand-made bricks and the machine pressure bricks?

- Withstanding voltage strength is not the same, the strength of the mechine-made is higher

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fireclay Brick for Furnace Price of Refractory Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords