All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

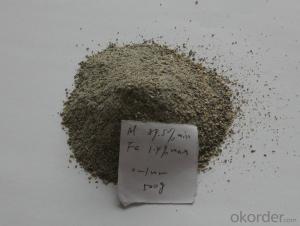

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

What are the common refractory materials used for lining ladle covers?

The common refractory materials used for lining ladle covers are high alumina, magnesia, and dolomite refractories.

How are refractory fibers manufactured?

Refractory fibers are typically manufactured through a process called melt spinning, where a high-temperature material such as ceramic or glass is melted and then extruded through tiny nozzles to form continuous fibers. These fibers are then cooled and collected to create refractory insulation materials with excellent heat resistance and durability.

What are the common types of refractory coatings for abrasion resistance?

The common types of refractory coatings for abrasion resistance include ceramic coatings, epoxy coatings, polyurethane coatings, and rubber coatings.

Can refractory materials be recycled?

Yes, refractory materials can be recycled. Refractory materials are often reused or repurposed after they have been used in high-temperature applications. They can be crushed, ground, and mixed with other materials to create new refractory products or used as filler material in other industries. Recycling refractory materials helps to reduce waste and conserve resources.

Wholesale Refractory Materials from supplier in Malaysia

With our extensive range of Refractory Materials and our affiliation with CNBM, a Fortune Global 500 company, we are confident in our ability to meet all your needs. Our focus on the Malaysian market ensures that we have a deep understanding of the local industry and can provide customized solutions.

Our team of experts is ready to assist you with any sales, quotations, or technical support you may require. We offer a wide selection of high-quality bricks, castables, and insulation materials to suit your specific requirements.

Having gained valuable experience in the Malaysian market, we have successfully completed numerous projects and are well-equipped to handle the unique challenges and demands of the industry. Our tailored solutions ensure the long-term success of your projects.

We pride ourselves on providing a hassle-free experience for our customers by offering one-stop procurement services. From product selection to delivery, we streamline the entire process, saving you time and effort. Our commitment to quality, reliability, and customer satisfaction sets us apart from our competitors.

Choose us as your Refractory Materials supplier and experience the difference of working with a trusted partner. Let us contribute to the success of your projects in Malaysia.

Our team of experts is ready to assist you with any sales, quotations, or technical support you may require. We offer a wide selection of high-quality bricks, castables, and insulation materials to suit your specific requirements.

Having gained valuable experience in the Malaysian market, we have successfully completed numerous projects and are well-equipped to handle the unique challenges and demands of the industry. Our tailored solutions ensure the long-term success of your projects.

We pride ourselves on providing a hassle-free experience for our customers by offering one-stop procurement services. From product selection to delivery, we streamline the entire process, saving you time and effort. Our commitment to quality, reliability, and customer satisfaction sets us apart from our competitors.

Choose us as your Refractory Materials supplier and experience the difference of working with a trusted partner. Let us contribute to the success of your projects in Malaysia.

Hot Search

- Monolithic Refractories in Bangladesh

- Ceramic Fiber Products in Finland

- Refractory Bricks in Madagascar

- Raw Materials For Refractory in Ecuador

- Raw Materials For Refractory in Brazil

- Raw Materials For Refractory in Chad

- Refractory Bricks in Zambia

- Raw Materials For Refractory in Samoa

- Refractory Bricks in Angola

- Raw Materials For Refractory in France