All Categories

- - Steel Wire Rod

- - Steel Coils

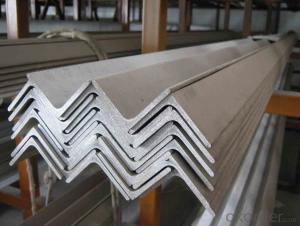

- - Steel Profiles

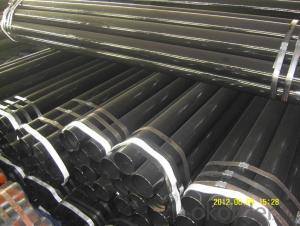

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the considerations when welding hot-rolled steel?

When welding hot-rolled steel, there are several key considerations. Firstly, the high carbon content of hot-rolled steel can lead to increased hardness and brittleness in the heat-affected zone, so preheating and post-weld heat treatment are often necessary to reduce the risk of cracking. Additionally, the presence of mill scale and surface contaminants can affect the quality of the weld, so proper cleaning and preparation of the surfaces is crucial. The welder must also be mindful of the potential for distortion and warping due to the rapid heating and cooling of the material. Finally, selecting the appropriate welding process and filler material is essential to ensure a strong and durable weld joint.

How is hot rolled steel used in the production of oil and gas drilling risers?

Hot rolled steel is commonly used in the production of oil and gas drilling risers due to its high strength, durability, and ability to withstand extreme conditions. It is utilized to manufacture the main structural components of the risers, such as the pipes and connectors, which must endure immense pressure, tension, and corrosive environments. The hot rolling process enhances the steel's mechanical properties, making it suitable for withstanding the demanding requirements of oil and gas drilling operations.

How does hot rolled steel contribute to the construction of high-rise buildings and its structural advantages?

Hot rolled steel plays a crucial role in the construction of high-rise buildings due to its numerous structural advantages. Firstly, the hot rolling process enhances the steel's strength, making it highly durable and able to withstand the immense loads and pressures experienced by tall structures. Additionally, hot rolled steel offers excellent flexibility and malleability, enabling architects and engineers to design complex and innovative building shapes. The material's uniformity and consistency further facilitate precise fabrication, ensuring accurate assembly and structural integrity. Moreover, hot rolled steel's fire-resistant properties make it a preferred choice for high-rise construction, providing enhanced safety for occupants. Overall, the exceptional strength, flexibility, and fire-resistance of hot rolled steel make it an indispensable material for constructing safe and resilient high-rise buildings.

Wholesale Hot Rolled Steel from supplier in Malaysia

Whether you require Hot Rolled Steel for construction, manufacturing, or any other application, we have the right products to meet your specific needs. Our range includes various grades, sizes, and finishes of Hot Rolled Steel, ensuring that you can find the perfect solution for your project requirements.

In addition to our comprehensive product range, we also offer a range of value-added services to enhance the efficiency and effectiveness of your projects. These services include custom cutting, bending, and fabrication, as well as just-in-time delivery to ensure that you have the materials you need, when you need them.

At our company, we prioritize customer satisfaction and strive to exceed your expectations at every stage of the procurement process. Our dedicated sales team is committed to understanding your requirements and providing you with the best solutions for your projects. We also offer competitive pricing, ensuring that you receive the best value for your investment in Hot Rolled Steel.

With our extensive expertise and resources, we are well-equipped to handle projects of any scale and complexity. Whether you require small quantities of Hot Rolled Steel for a specific project or need a continuous supply for ongoing operations, we can fulfill your requirements efficiently and effectively.

Choose us as your trusted supplier of Hot Rolled Steel in Malaysia and experience the benefits of partnering with a leading company in the industry. Contact us today to discuss your requirements and let us assist you in finding the perfect Hot Rolled Steel solutions for your projects in Malaysia.

In addition to our comprehensive product range, we also offer a range of value-added services to enhance the efficiency and effectiveness of your projects. These services include custom cutting, bending, and fabrication, as well as just-in-time delivery to ensure that you have the materials you need, when you need them.

At our company, we prioritize customer satisfaction and strive to exceed your expectations at every stage of the procurement process. Our dedicated sales team is committed to understanding your requirements and providing you with the best solutions for your projects. We also offer competitive pricing, ensuring that you receive the best value for your investment in Hot Rolled Steel.

With our extensive expertise and resources, we are well-equipped to handle projects of any scale and complexity. Whether you require small quantities of Hot Rolled Steel for a specific project or need a continuous supply for ongoing operations, we can fulfill your requirements efficiently and effectively.

Choose us as your trusted supplier of Hot Rolled Steel in Malaysia and experience the benefits of partnering with a leading company in the industry. Contact us today to discuss your requirements and let us assist you in finding the perfect Hot Rolled Steel solutions for your projects in Malaysia.