All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are recycled aluminum profiles integrated into the manufacturing process to reduce waste?

Recycled aluminum profiles are integrated into the manufacturing process by collecting and processing scrap aluminum, melting it down, and then extruding or shaping it into new profiles. By utilizing recycled aluminum, manufacturers can minimize the need for extracting and refining virgin aluminum, which significantly reduces waste and energy consumption. Additionally, incorporating recycled aluminum profiles in manufacturing helps divert aluminum from landfills, promoting a more sustainable and circular economy.

How do you calculate the load distribution and stress analysis for aluminum profile-based structures?

To calculate load distribution and stress analysis for aluminum profile-based structures, several steps can be followed. First, the applied loads on the structure need to be identified, including both static and dynamic loads. Then, the load distribution can be determined by analyzing the geometry, connections, and support conditions of the structure. This involves considering factors such as the shape and dimensions of the aluminum profiles, the arrangement of the members, and the type of connections used.

Next, stress analysis can be performed by applying engineering principles and utilizing software tools or mathematical equations. The analysis accounts for factors such as material properties, applied loads, and boundary conditions. By considering the bending, shear, and axial stresses, the structural integrity and performance of the aluminum profile-based structure can be assessed. Additionally, factors such as deflection, buckling, and fatigue should be evaluated to ensure the structure's safety under different loading scenarios. Overall, a comprehensive load distribution and stress analysis is crucial for designing and evaluating the strength and stability of aluminum profile-based structures.

How are aluminum profiles used in the marine and shipbuilding industries?

Aluminum profiles are extensively used in the marine and shipbuilding industries for their lightweight, corrosion-resistant, and high-strength properties. These profiles are commonly used for constructing ship hulls, decks, superstructures, and various other components. They offer excellent structural integrity, durability, and ease of fabrication, making them ideal for enhancing fuel efficiency, reducing weight, and improving overall performance in marine vessels. Additionally, aluminum profiles are utilized in the construction of marine equipment, such as gangways, ladders, railings, and cabin interiors, due to their versatility, low maintenance requirements, and resistance to harsh marine conditions.

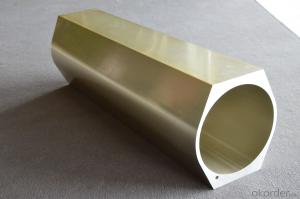

Wholesale Aluminum Profiles from supplier in Malaysia

Our Aluminum Profiles are manufactured using high-quality materials and advanced technology, ensuring durability and precision. We offer a wide range of profiles, including standard and customized options, to meet the specific requirements of our customers.

In addition to supplying Aluminum Profiles, we also provide a range of services to support our customers throughout their projects. This includes assistance with design and engineering, as well as technical support and on-site installation guidance. Our team of experts is dedicated to delivering excellent customer service and ensuring customer satisfaction.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to provide competitive pricing and efficient procurement solutions for our customers in Malaysia. We are committed to delivering high-quality products and services, on time and within budget.

Whether you are working on a small-scale project or a large-scale development, we have the capabilities and experience to meet your Aluminum Profiles requirements in Malaysia. Contact us today to discuss your project needs and let us provide you with a comprehensive solution.

In addition to supplying Aluminum Profiles, we also provide a range of services to support our customers throughout their projects. This includes assistance with design and engineering, as well as technical support and on-site installation guidance. Our team of experts is dedicated to delivering excellent customer service and ensuring customer satisfaction.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to provide competitive pricing and efficient procurement solutions for our customers in Malaysia. We are committed to delivering high-quality products and services, on time and within budget.

Whether you are working on a small-scale project or a large-scale development, we have the capabilities and experience to meet your Aluminum Profiles requirements in Malaysia. Contact us today to discuss your project needs and let us provide you with a comprehensive solution.