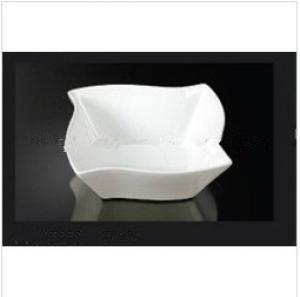

Factory Direct Wholesale Porcelain Candle Holder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 Pieces pc

- Supply Capability:

- 3000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Certification: CIQ ,FDA,SGS etc

2.Dishwasher and microwave safe

3.MOQ:3000 pcs

4.Various colors available

5.PAY:T/T,L/C

Porcelain Candle Holder

Feature:

1.Material: porcelain,ceramic, durable porcelain

2.size: (cm)

(1).Length: 15.3cm

(2).Height: 6cm

(3).Width:6.3cm

3.we can make different style,size,color according to clients' request

4.we can open the new mould according to the buyer's original sample and technical drawings.

5.printing set up: we can set up new printing according to buyer's artwork in ai.format.with resolution.

6.microwave and dishwasher safe.

7.High quality & different kinds of designs and shapes are available.

8.Packing: customers' requirements are available

- Q:Please help! I have a ceramic oneAren‘t those supposed to be better?

- a ceramic straighter won't burn your hand when your using it as much as a regular one will :)

- Q:The difference between ceramic, enamel, porcelain?

- The ceramic is prepared from clay, quartz and feldspar and other natural mineral raw materials according to different formula, after processing, molding and sintering, the chemical composition depends on the use of natural raw materials and formulations, different regions of the different kilns of ancient ceramics due to the different raw materials, different and firing process recipe is different, the glaze of chemical composition, structure and physical properties of micro will have their own characteristics. If the collection of different kilneye excavation have reliable stratigraphic ceramic specimens were systematically studied, the accumulation of data such as chemical composition data (including major and minor elements and trace elements) to establish a database, and use the proper treatment method, such as multivariate statistical analysis methods for data processing, to find out the characteristic significance the law. To study the chemical identification of ceramic composition, microstructure, physical properties and firing process, and the chemical data of ancient ceramics and the known kilneye and the age and the chemical composition of the composition of the data processing, and then integrated microstructure, physical properties and firing process and other aspects of the information may make an appraisal on the ceramic.

- Q:im 16 and im going to get ceramic braces for an overbite. the dentist said ill have to wear them 18-24 months. i dont want to get metal braces so im going with the ceramic. do people notice them ?does it hurt when they put them on?did you like them?how long did it take for you to start eating solid food again?what cant you eat? plaese help share your experience with braces ) thank you im going to get them in a week

- I have the consistent steel braces, I am 22 and I received them due to the fact compaired to the ceramic braces they are going to rise up to rough meals and I can get one of a kind colours. To consider that you are going to truthfully now not devour what you are now not meant to is loopy, I nonetheless devour some thing I desire, however I care for my braces too. Doctors inform young adults and youngsters that designated matters are unhealthy, due to the fact young adults and youngsters don't seem to be very accountable in terms of cleansing and taking care of their braces. Its as much as you, however ceramic ones will have you again within the workplace getting them constant extra commonly then you definately'd desire to be. Metal ones don't seem to be that unhealthy, and I have not had a trouble with them but and I virtually performed with my therapy. Which ever you opt for, well good fortune with them!

- Q:Best way to apply rhinestones to ceramic?

- Can have a look inside the oil cap to see if there has been moisture there - will appear as water bubbles

- Q:PLEASE HELP!

- using in production or just using it - like a cook will use ceramic bowls for putting food in, but is not involved in making them. Or somebody may sell ceramics but not make it. on the fabricating end. potter, dental ceramic technician, ceramic engineer, sculptor, factory worker in ceramics tableware production, product designer for ceramic products would be a few.

- Q:I bought ceramic Duralast gold brake pads?? do i need something else or will these be fine for the car and the rotors or whatnot??

- tricky subject. browse on to the search engines. it can help!

- Q:im a sophomore in high school and i LoVe ceramics and my teacher was talking about it and i want to know what it is!!!!!!

- If you have a G-series van that has a bad axle, ONLY replace it with an axle from a G-series van.

- Q:HiI have some ceramic beads which were used as electric insulaters inside a vacuum coater and as a result are coated by some metals like Ti,.!I used HCl 36% and dipped them for a few hours in it but nothing happaened! any idea?!

- Naturally, the reagents required will depend on what metal(s) are in the deposits. If the metal is titanium, as you suggest, then it will take something like a nitric-hydrofluoric acid mixture to do the job. Generally, the mixture would be on the order of concentrated nitric acid 2 parts, hydrofluoric acid 1 part, and water 1 part by volume. NOTE: Although nitric acid has its hazards, the hydrofluoric acid is an especially dangerous and insidious material. It causes severe burns that are not immediately painful and may not be apparent until hours later when it's too late to do much good for them. If you have it available, ammonium bifluoride is a somewhat safer and equally effective alternative to the hydrofluoric acid. Whatever you use, be sure you understand the dangers and use appropriate safety gear. Of course, there's the possibility that the fluorides will also etch your ceramics - it depends on what they are. Good luck with this project. Be sure to try small test samples before going large-scale.

- Q:I have a well seasoned clay chimnea that my husband brought me home from south Tex. several yrs ago. I‘d like to give it some pizazz! What would ceramic glaze do to it? How long and hot would the fire have to be kept for the galze to do it‘s stuff? I‘d love some deep reds with gold and turquoisesouthwestern flare!

- You don't need it. It's just for show. The Wii Wheel is just a fancy housing for a Wiimote. You can use the Wiimote without it. You can also use a GameCube controller, the Classic controller of the Wiimote/Nunchuck combo.

- Q:This may sound like a lil‘ bit crazy. We have an experiment and we can‘t find clay! So, I couldn‘t think of an alternative for ceramic clay I thought of mud :(

- try a scrap yard -- one of those places that buy metal

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong,China (Mainland) |

| Year Established | 2009 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | North America 8.5 South America 8.5 Eastern Europe 12.75 Southeast Asia 8.5 Oceania 4.25 Mid East 17 Eastern Asia 17 Western Europe 8.5 Domestic Market 15 |

| Company Certifications | Export products quality certificate;Production Assessment Certificate;Sole proprietorship business license |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Guangzhou,Shantou,Shenzhen |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Factory Direct Wholesale Porcelain Candle Holder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 Pieces pc

- Supply Capability:

- 3000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products