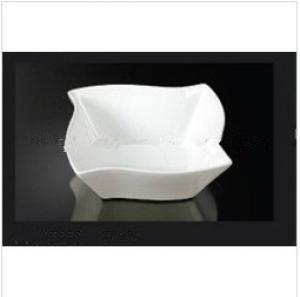

Restaurant Salad Soup Porcelain Bowl for Hotel Importer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Model Name | Durable Porcelain, Restaurant dinnerware, tableware set ,dinner set |

Size | 8" 9" 10" 12" 13" 14" Inch (Can be customized size) |

Color | White ( Super White/ Creamy white). & Your decal design can be printed on it. |

Material | Ceramic, Porcelain,Crockery,Stoneware |

|

|

Certificates | CE/EU, FDA, SGS, CA65 |

Grade | A/B |

|

|

In every sector | Hotel, Restaurant, Home, Banquet hall, Buffet, Cafes&Bar, Leisure venues, Casinos& Stadia, Public sector ( Education, Health, Government establishments ) Care home& centers. |

Features | 1.High quality standard. Suitable for high class hotel & restaurant |

2.Low water absorption, Temperature extremes | |

3.Wearable, Glaze durable, Edge chip resistance | |

4.Firing at high temperatures, the more dense matrix sintering, glaze of goof quality clay. | |

5.Dishwasher and Microwave safe | |

6..Lead-free, Eco-friendly, Unique | |

Advantages | 1: Factory directly, Premium porcelain, Competitive price, Fast delivery, Diverse designs. |

2.Unique ceramic plates design with high quality and competitive price, hand-painted, decal or color glazed. | |

3.Shapes, sizes, decal design and colors can be tailor-made. | |

4.Strict quality control and management implimented | |

5. Moulding: we can open the new dinner set mould according to customer's original sample and technical drawings |

- Q:I have these ceramic bowls with bright color glazes: yellow, orange, lime green, blue. If I try to microwave something in them, the bowl gets scorching hot and the food stays cool. What might be in my bowls that‘s absorbing microwaves?

- Moisture in the ceramics is driven out by firing, but this isn't always done completely. If there is still moisture in the ceramic when it is glazed, the glaze will trap the moisture in the ceramic. Water molecules are polar, and the microwaves cause them to rotate back and forth, which is the atomic motion we call heat. If there are water molecules in the ceramic, they will heat up. There isn't anything you can do to fix it.

- Q:Please, could someone tell me what is less damaging for hair? Im on to buy crimping iron but im not sure about the titanium one. On another site, I don‘t know anything about them. Please help.

- i agree with Miss Elaina :) Ceramic plates lock in the moisture which is less drying to your hair than metal or titanium plates. Also, ceramic plates make hair more smoother and shinier and the hair looks healthier because there is less dammage :-) **but you should always use a heat protectant anyways to minimize even more dammage so you dont burn your hair and get major split ends. Hope this helps! ?MoonlightFairy?

- Q:I had numerous art classes trailing from middle school and took 3d art and ceramics in freshmen year of high school.I like drawing but didn‘t truely enjoy art classes until I had ceramics. Right now I‘m taking classes to perpare for a career in computer graphics/mulitmedia and networking.My only interest aside animation is ceramics, but it doesn‘t look like a promising pathway. Can someone give me their personal experience studying/working as a Ceramic Artist?

- Sand, peat moss, cow manure, lime. Get all of these at your local home improvement store. Roto-till in grass clippings and leaves in the fall. They will decompose over the winter adding nutrients to the soil.

- Q:I really want ceramic braces but I don‘t want to look like a dumbass if they get stained? Any tips or foods to avoid?

- i might circulate with steel because of the fact they artwork speedier than the ceramics. And after a whilst the sparkling ceramic ones gets grimy and noticable. Plus, you are able to shave some months off the quantity of time you need to positioned on them and shop funds.

- Q:Are ceramic braces only for adults?

- Most orthodontists offer clear ceramic braces to anyone at any age. The ceramic braces work the same way as metal braces, except they can be a little more fragile. Many orthodontists will not put ceramic braces on the bottom teeth because your top teeth may bite into them and cause damage to your top teeth.

- Q:Ceramic pot for a long time, how to clean the dirt?

- Put the cleaning agent, and then use a soft brush to wash

- Q:I have a ceramic plate that is very shallow and is almost even in its concavity. Yet in the middle, there is a slight bulge up.For an art project, I need to get the plate perfectly (or close to perfectly) concave, so I‘d like to sand down that middle part.Does anyone have any tips on how I can do this, preferably by hand?Thanks!

- throw a treat in there or buy him some steps to climb up.

- Q:i bought some other cheap brakes from a neiborhood little auto shop for about 12 dollars after a month they were squeaking like there was no tomorrow you could hear me coming from a mile so i just bought some ceramic brakes from pep boys how good are ceramic brakes

- Getting up at 5:45 a.m.

- Q:The electric cooker can burn it in gas

- Best not to, because of the high temperature gas stove fire, electric cooker ceramic liner is porcelain, and thick, will make the electric cooker inside and outside the uneven heating and burst

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong,China (Mainland) |

| Year Established | 2008 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe South Asia |

| Company Certifications | FDA Test Peport;EU 2005/31/EC;SGS Test Report;California Safe Drinking Water and Toxic Enforcement Act part Proposition 65 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shenzhen,Guangzhou,shantou |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Restaurant Salad Soup Porcelain Bowl for Hotel Importer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords