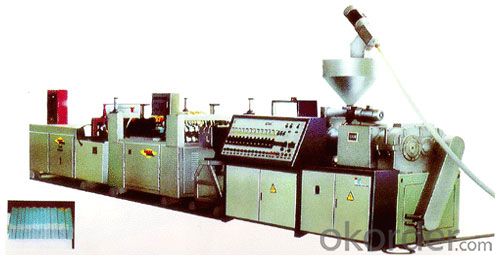

Extruding Wavy Plastic Plates Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Extruding Wavy Plastic Plates Production Line

With SJSZ-60x22 Taper Twin-Screw Extruder combined with corresponding wavy plate molder,drawing auxiliary machine and cutter, SJLB-60x22-1000 set for extruding wavy plastic plates can continuously produce the coloured,weather-resistant and flame-retardant wavy UPVC plates used in the construction. If replacing the relative pare, it can also produce flat and grid plastics plates. The set has the characterisitics of good plasticizing,stable performance,compact structure,high automatic degree and convenient operation, is the ideal productive equipment for construction manufactures.

Model of Main Machine | SJSZ-65 x 132 |

Die Form | Coat Hanger plane Die L=1000mm |

Molding Unit | |

Great Wave | R=15 H=16.5 Pask Distance=63mm |

Little Wave | R=9 H=8 Pask Distance=36mm |

Length of Molding Roll | 1000mm |

Motor Power | 1.5kw(Frequency-Changing Requlation) |

Dimension of Cooling Mold | 1000mm x 540mm |

Cooling Mode | Cooling Water |

Drawing Speed | 0.5 – 5m/min |

Drawing Power | 2.2KW(Frequency-Changing Requlation) |

Cutting Mode | Shearing(Oil Pressure) |

Cutting Follower Distance | 500mm |

Working Pressure of Gas Line | 0.4 – 0.6Mpa |

Conical twin screw plastic extruder:

Features Specifications:

1. Model SJZ series conical twin screw extruder is a kind of special equipment for extruding PVC compound. With different kinds of molds and auxiliary machines, it can produce all sorts of PVC plastic pipe, profile, plate material, sheet material, bar material and granulation.

2. The conical twin screws have applied oil cooling system. Barrel is cooled by special wind cooling system.

3. The conical twin screw extruder system has applied special computer control. According to customers requirements, most reasonable structure of conical twin screw can be made so as to achieve best plasticity performance and material quality.

4. The conical twin screw is made by high precision special digital screw miller; extruding property can be highly harmonized. It has firstly introduced advanced technique of producing screw with variable pitch and depth, so that the material can be more softly sheared and cut.

5. The distribution box is specially designed, pull force bearing is fully imported, and the drive life span can be prolonged. It can bear larger extruding pressure.

6. The electrical system has mainly applied imported parts, it has multiple alarm system, and there are few problems which can be easily eliminated. The cooling system has applied special design, heat emission area is enlarged, the cooling is rapid, and temperature control tolerance can be ± 1degree.

All SJZ Series Conical Twin-Screw Extruder Technical Parameter:

Model | SJZ-51 | SJZ-55 | SJZ-65 | SJZ-80 | SJZ-92 |

| Screw Dia.(mm) | 51/105 | 55/110 | 65/132 | 80/156 | 92/188 |

Max. Rotating speed(rpm) | 40 | 38 | 38 | 37 | 36 |

| Main Motor(kw) | 18.5 | 22 | 37 | 55 | 90 |

Capacity(kg/h) | 80~100 | 100~150 | 150~250 | 250~380 | 380~700 |

| Center height(mm) | 1050 | 1050 | 1050 | 1050 | 1100 |

| Net Weight(kg) | 3000 | 3500 | 4000 | 5500 | 8000 |

| L*W*H | 3.6*1.1*2.1 | 3.6*1.1*1.2 | 4.2*1.5*2.4 | 4.7*1.5*2.4 | 6*1.6*2.5 |

Plastic Pipe Extruder/Plastic Extruders:

Different types of extruders With different sorts of molds and auxiliary machines,

it can produce all sorts of PVC plastic pipe material, profiled material, plate material, sliced material, bar material and granulation.

It can also extrude PP.PE pipe at high speed by changing special barrel.

Computer control or conventional control is optional.

According to customer's requirements, most reasonable screw can be made so as to achieve best plasticity state and material quality.

The screw is made by high precision special digital screw miller; extruding property can be highly harmonized.

It has firstly introduced advanced technique of producing screws with variable pitch and depth, so that the material can be more softly sheared and cut.

The distribution box is specially designed, pull force bearing is fully imported, and the drive life span can be prolonged.

It can bear larger extruding pressure.

- Q:What mechanical products do you use to make this plastic product?! The more detailed, the better!

- I'm not sure about the mold design. You can find a device and ask for advice. Generally, they will be responsible for design and training

- Q:How can rubber products be machined?

- The types of mechanical processing of plastic products, mainly cutting, punching, cutting, drilling, thread processing, laser processing, etc..

- Q:How much do you need for it? How about the raw material?

- The production of plastic sandals is the use of injection molding machine, injection molding machine in general to choose 500g-1000g, matching plastic crusher, drying machine, injection molding machine that usually adopts water cooling mold, also need cooling water system.

- Q:What kind of machine is needed for the production of plastic products?

- Seventy thousand or eighty thousand an injection molding machine, a crushing machine, a drying machine forty thousand or fifty thousand, workshop, rent, labor, water and electricity to ten thousand months Duoliangwanyi, mold materials, another operator, of course cost large scale is low.

- Q:profit is not big, about how much investment, please expert advice, mainly to supply the market and small supermarkets

- I just do this, the raw material is used PE, equipment, there are mainly blowing machine, punching machine, if you want to print, then also the printing press, there are other stirring what ah!

- Q:Please expert pointing. How high is the profit?. Where are the machines reliable in quality?.

- Profit is not to say, 2000 before doing a ton of 500-1000 net profit, now do a ton of only about 300, but also to do good, large amount of the profit was also lower (puerile) now what things are transparent, not hide what the difference, and too many fakes (it is impurity) also, the factory debt, lead to large investment (scrap price is high, the factory as a result of the large investment in arrears), reliable quality machine: if the water feed on a number of Shandong (lack of the low yield), if the dry material (sheet) on a number of Guangdong Zhongshan presses, the Chinese star can also.

- Q:Where has the machine which sells the plastic processing, wants the true, begs the answer

- Jiangsu and Zhejiang provinces are many (New), Heilongjiang has many families also to buy (old).

- Q:What kind of machine does plastic products factory use to produce plastic products?.

- Plastic and metal crafts of mass production are painted on the surface, generally divided into paint (pigment), color and polishing, color, usually by spraying, coloring and electroplating coloring.

- Q:Are the fragrance of poisonous substances poisonous in plastic products?

- Poisonous, smelling, and dying so fast, so many people with mechanical hand out, we repair the manufacture of mechanical hand

- Q:Plastic food bags processing machines where there is ~ how much is the price, I know

- You mean the production of food bags? A machine or a sealing machine? Vacuum packaging machinery, food packaging bags, I can provide you with!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Extruding Wavy Plastic Plates Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords