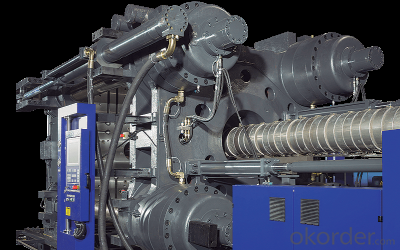

Large two-platen (Direct Hydraulic Clamping) Injection Moulding Machines

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 SET unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Description of PLASTIC INJECTION MOLDING MACHINE-C SERIES

128J full hydraulic two-platen injection molding machine is special designed for plastic injection moulding.

Full hydraulic two-platen injection molding machine for plastic, relying on independent intellectual property rights, make full use of the internal groups advanced technology HOYEAelectrohydraulic control,HOPEA(microcomputer frequency Conversion control) and precision injection molding machine developed independently by injection molding machine experienced engineers in our Machinery. With the latest European Hydraulic Design Concept, Machinery electro-hydraulic control specialists make great efforts to build the plastic injection equipment with environment-friendly and energy-saving.

Advantage of PLASTIC INJECTION MOLDING MACHINE-C SERIES

Super-Large space, we can make machine as the requirement of customers products, with parameters strong adaptability.

Short clamping stroke line, is only the distance between main moving platen and fixed platen, mould- clamping is high rigidity and precision.

Main moving platen adopts oil-less self-lubricating copper sets guide, ensure clean production environment. Support sliding feet can choose linear slide way guide, which greatly enhance the rigidity of clamping unit and service life of mould..

Using the latest German sealing technologies and products, ensure the sealing performance high.

Hydraulic system adopts proportional integrated instrument control system to ensure the mould transfer rapidly, stably.

Electrical system uses Siemens controller, with high speed, good stability, high performance and good scalability.

Specification of PLASTIC INJECTION MOLDING MACHINE-C SERIES

Item | Unit | Parameter | ||

Screw no | A | B | C | |

Screw Dia | mm | 38 | 42 | 45 |

Screw LD ratio | 23.2 | 21 | 19.6 | |

Theoretical capacity | cm3 | 209 | 256 | 294 |

Injection weight | g | 190 | 233 | 267 |

Injection Pressure | MPa | 243 | 199 | 173 |

Injection rate | g/s | 100.9 | 123 | 141.2 |

Plasticizing capacity | g/s | 14.7 | 18.2 | 20.6 |

Max. screw speed | rpm | 200 | ||

Clamping force | kN | 1280 | ||

Moving mould distance | mm | 560 | ||

Tie bar spacing | mm | 420×420 | ||

Max.Daylight | mm | 730 | ||

Min. mould thickness | mm | 170 | ||

Ejector stroke | mm | 150 | ||

Ejector force | kN | 41 | ||

Ejector bar amount | 5 | |||

Max.pump pressure | MPa | 17.5 | ||

Pump motor power | kW | 15 | ||

Heating power | kW | 7.5 | ||

External dimension | mm3 | 4500×1600×2100 | ||

Weight | Kg | 5500 | ||

Material cylinder capacity | L | 25 | ||

Oil tank capacity | L | 265 | ||

Package of PLASTIC INJECTION MOLDING MACHINE-C SERIES

Wooden box packed, suitable for train or sea worthy delivery.

FAQ:

1. Why Choose us?

CNBM is a stated owned company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

3. Can you provide sample?

Yes, we can offer free sample for you.

4. Payment terms?

We can accept L/C, T/T etc.

5. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q:Such as "computer embroidery processes" - Programming - sample preparation, shipment packing production computer

- Process flow of plastic products1. Preparation before moldingA, grain preheating and drying: if the grain is affected with damp, it should be dried;B, insert preheating: in order to reduce the gap between the cooling shrinkage value of metal and plastic, the larger metal insert should be preheated.C, barrel cleaning: when changing the product, changing the raw materials, cleaning cylinder is required.2, injection molding process feeding - plasticizing - injection - holding pressure - cooling - die opening piecesA, feeding: each feeding should be quantitative, in order to ensure uniform plasticization;B and plasticization: the grains are heated to a molten state in a barrel;C and injection: the injection molding machine uses a screw to inject molten plastic into the mold cavity;D, keep pressure: after the mold is finished, maintain the pressure for a certain time;E and cooling: keep cool for a certain time in the mold cavity;F, mold opening parts: mold open, take out the product.3, plastic parts after treatment: plastic parts after treatment:A, remove the fly edge, material handle.B, inspection and packing.

- Q:How do we calculate the cost?

- So many people bought equipment and started, most of the friends have just started, mainly chemical fiber bags (PP woven bags) granulation, plastic film granulation, plastic bottles, broken materials, and so on.2, followed by the main problem is the use of equipment:1). Performance of the equipment are not familiar with the problems of using too much, such as temperature control is not good (low price devices do not have automatic temperature control system, through experience), products can not achieve the desired requirements, the color is not good, drawing off a serious, low yield, often blocking filter, cutting unevenness, severe adhesion.2) raw materials sorting is not clear, cleaning is not in place, impurities, broken bar serious, bad color. The same raw materials, the same approach, the product is not as good as others, the price is far from.3), procurement of raw materials, usually all recycled plastic, when you formed a batch production, to ensure the supply of raw materials can not be too much, impurities in raw materials procurement, and even pit you encounter people, buy a home is water, stone bag.4) sales problems: I don't know who sells the products. I don't know what the price is, or even say you have such and such problems.Moreover, the beginning of production, it is impossible to form mass production, small amount of bad sales, because customers need to be generally enough to a car to load, 2T-3T is not good, and more afraid of production, fear of backlog.

- Q:Want to buy an injection molding machine to do some plastic products, equipment about how much money ah? What needs to be prepared?

- Tens of thousands of yes, but the quality of the product to do the Department of stability, and later maintenance costs are very expensive, but also trouble, or choose the brand well. Investment step in place.

- Q:What kind of equipment does the plastic bottle crush processing plant need?

- The initial processing of plastic bottles requires crushing machines or crushing washing machines, sheet cleaning machines, and drying machines.Plastic mill refers to the crushing of various kinds of plastic and rubber, such as plastics, profiles, tubes, rods, threads, films, waste rubber products. The pellets can be directly extruded for production.

- Q:Do waste plastics recycling processing, the state subsidies, and now the prospects are good?

- Plastic machinery production of this piece, I personally think that Shandong is still a lot of production enterprises. All regions have done, and quite a lot, forming a production chain of processing. Shandong outstanding people, saints land, people are very real. Suggest that you go to Shandong site visits, compared to, not light, cheap, the most important thing is to look at the quality of the machine, after-sales service. Just like my friend bought a machine, the price is not very cheap, but the quality of the machine is good, and there is nothing wrong with it.

- Q:What kind of units do you need to process plastic injection products?I own the business, there are plastic injection molding machine more than, can produce all kinds of plastic products, order ~ unit in Hangzhou ~!

- Ji'nan high tech Development Zone, Xin Ruichang machinery mold factory specialized in processing all kinds of plastic products, the company covers an area of more than 30000 square meters, hundreds of employees, the company has owned injection molding workshop, mold manufacturing workshop, foam tooling workshop, assembly workshop covers an area of 10000 acres, the company currently has 3300 tons, 1800 tons, 1300 tons, 1000 tons other large and small injection molding machine more than 20 Taiwan, a maximum of 30000 grams of plastic products production and processing,

- Q:Types of plastic machinery

- There are many kinds of plastic machinery. According to the processing process is divided into extruder, injection molding machine and blow molding machine three major categories. In the screw extruder is under the action of the molten plastic extrusion through fixed shape extrusion, water cooling after cutting in the traction machine under the same section is mainly used for a variety of products. A large number of continuous production, such as pipe, rod profiles, also can be used for plastic modification and granulation.The basic mechanism of extrusion is simple - a screw rotates in the barrel and pushes the plastic forward. The screw is actually a ramp or slope that is wound around the center layer. The aim is to increase the pressure to overcome the greater resistance. Is an extruder, there are 3 kinds of resistance to overcome: solid particles (feed) on the cylinder wall friction and screw rotation before laps (feed) the mutual friction between them; melt in the cylinder wall adhesion; melt pushed forward when the resistance of the internal logistics.It is divided into single screw extruder and twin screw extruder. The injection molding machine is injecting molten plastic into the mold, cooling after the product. The use is very extensive, according to the different use of plastic, where is different. The injection molding machine is used in processing machinery and plastic processing industry the largest amount, not only a large number of productsCan direct production of injection molding machine, and it is composed of injection stretch blow moulding equipment key.

- Q:What machine does the pattern design of this mass produced plastic product use?

- Hello, let me answer the question for you: you can open your mobile phone, Baidu, and then enter your current location, and then enter the address you want to query. The Baidu maps will automatically navigate the nearest route for you.

- Q:How much profit can a ton earn? Is it difficult to operate the program?

- Sichuan Ziyang shunmin plastic machinery specializing in the production of plastic granulator needs can choose according to the type of subjects ~ configuration price at around 50 thousand ~ a profit of around 8000

- Q:Which plastic is suitable for processing 3mm threaded holes and is best resistant to corrosion?

- Nylon plastic is suitable for processing 3mm thread hole, nylon is widely used in chemical machinery, corrosion protection equipment, gear and parts, broken material.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Large two-platen (Direct Hydraulic Clamping) Injection Moulding Machines

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 SET unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords