Supply Hot sale china PVC PPR PE plastic pipe production line(extrusion line/extruder machine/making machinery)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Supply Hot sale china PVC PPR PE plastic pipe production line(extrusion line/extruder machine/making machinery)

This production line adopts unique design, seperated BM type high efficiency screw, high degree of automation, convenient operation, continuous production, it is stable and reliable. The production of plastic pipe, has the characteristic of heat resistance aging resistance environmental stress crack resistance,cracking resistance,creep resistance, is the first choice of product of inter-city gas pipeline.

This product can also produce large-diameter PE water supply pipes, and the pipes is non-toxic, tasteless, no corrosion, anti-ageing, weatherability and so on many good characteristics, such as can be widely used in not more than 45 degrees of water supply pipe buried or surface, replacing zinc-plated steel, cast iron pipe, tube of cement ideal products.

Drawing upon profuse experience in this field, we have innovatively manufactured a number of state-of-the-art machines which enables our customers to pursue the most while keeping a possibly lowest cost. The Plastic Pipe Extrusion Line from FAR EAST(CHINA) can use a variety of polymers such as PE, PP, PVC to produce a broad range of plastic pipes with solid quality.

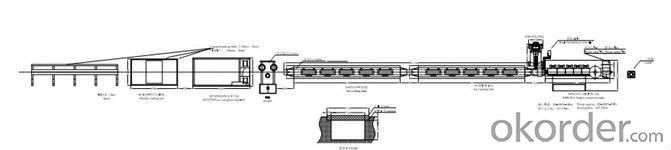

Main Configuration of large caliber Plastic Pipe Extrusion Line

Extruder/ Vacuum Shaping part/ Cooling part/ Haul-off Device/ Cutter/ Stirring-up Rack

Specification of typical single screw extrusion lines

|

- Q:What's the price? How much does it cost to run a processing plant? What's better about that one?

- There are two kinds of plastic bottles: injection, blow and blow.Injection blowing is the two step, that is, injecting the bottle embryo first and then blowing it into a bottle. The machine mainly has the injection molding machine and the bottle blowing machine and the auxiliary machine and the corresponding mold.

- Q:now have no market quite suck me how to go find the market ask predecessors and friends hope that they can point out a way to thank you

- The reason why there is no sales price or quality problems?AskNeither price is lower than others, quality can be problem without production licenseChasing the answerDoes it depend on relationships?

- Q:What machines do you need? Where can I get the raw material? Thank you

- This kind of enterprise does not need too much liquidity, equipment and machinery to the company of large equipment manufacturing orders, raw materials can be recommended if in order to the factory machinery, because this kind of raw material enterprises generally left in the information equipment manufacturing enterprises, facilitate the development of business.

- Q:Is there any pollution in the processing of plastic raw materials?

- Yes, we have.The plastic itself contains chemicals, in the production process, will react with other substances, produce some odor and so on, so in the production environment must be ventilated, and will produce gas in the process of mechanical production, in production and after the residue, waste water and so on, these are the production of pollution.

- Q:What machine does the pattern design of this mass produced plastic product use?

- Hello, let me answer the question for you: you can open your mobile phone, Baidu, and then enter your current location, and then enter the address you want to query. The Baidu maps will automatically navigate the nearest route for you.

- Q:Which kind of engineering plastics has good processability?It requires small deformation and high machining accuracy when subjected to force

- Organic glass rods and plates, PTFE rod material, nylon rod, PVC sheet and other mechanical processing performance is good.

- Q:Are the fragrance of poisonous substances poisonous in plastic products?

- Poisonous, smelling, and dying so fast, so many people with mechanical hand out, we repair the manufacture of mechanical hand

- Q:I don't know how much money it needs! Raw materials are used plastic baskets!

- Production of this material, a basic set of machinery and equipment investment of about 70 thousand, if the amount of large, you can choose to configure the machine at around 200 thousand.

- Q:I want to make some plastic products. Thank you。 FiveThe four type: first, a one or two meter long, hard, but bent plastic tube. Then there's something like the front end of the syringe. And then a small plastic kettle. Finally, a small thing that can be secured to the mouth of the pipe.

- The first thing for PE is certainly no problem, PE pipe can be bent, there are a variety of diameters and specifications to the number of how many, still a little hard oh.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Supply Hot sale china PVC PPR PE plastic pipe production line(extrusion line/extruder machine/making machinery)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords