double wall corrugated pipe production line high speed big diameter plastic pe pipe product line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

double wall corrugated pipe production line, high speed big diameter plastic pe pipe product line

| Features of plastic pe pipe product line |

1) Optimizing diameter range of pipe production, can produce bigger diameter range with same investment. 2) Smooth and stable operating water cooling system, ensure high speed production. 3) Can replace mould block quickly, to save waiting time. 4) Most intelligent control on water, air pressure and electricity, easy to operation, monitoring and control. 5) Die head with partial wall adjustment function, convenient and easy to operate. 6) Corrugator section with quickly open function, greatly convenient to trouble shooting, equipment maintenance and other operations. 7) Multistage vacuum molding system, easy to forming, stable operation. 8) Central lubrication system. 9) Remote fault diagnosis system (Optional). |

| Factory of plastic pe pipe product line |

1) Engaging in innovating new technology, devoted to research and develop new technology on plastic machinery for decades of years. 2) Combining the world most advanced technology and new material. 3) Excellent skilled workers, especially R&D engineers, technicians with decades of experience in this industry. 4) First-class after sale service, with the most competitive price. |

| Applications of Double Wall Corrugated Pipe |

1) Cable protection pipes 2) Drainage pipes 3) Other special pipes |

| Suitable Material of plastic pe pipe product line |

HDPE, PP, PVC and other polymers |

| Corrugator Section Specification of plastic pe pipe product line | ||||||||||||||||||||||||||||||||||||||||

|

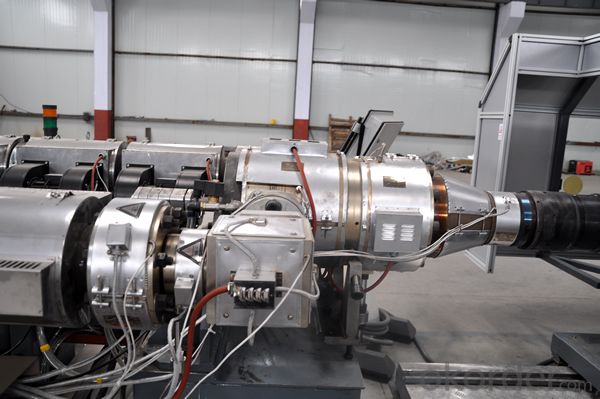

| Detail pictures of plastic pe pipe product line |

Automatic feeder with self-dry function, space saving and efficient. Long effective screw, excellent melting effect.

Shorter die head, low pressure, low temperature, high efficient (patent).

Die head with partial wall adjustable function, convenient and easy to control.

Corrugator with cover, safe. Also with quick open function, great convenient for trouble shooting, maintenance and other operations.

Aviation aluminum mould blocks, very durable and long service life.

Horizontal water cooling system, high efficient and time saving.

Dustless double hydraulic cutter

Automatic unloading device.

Intelligent control on water, air pressure and electricity, easy to operate. Comprehensive protect for all kinds of wire, safe and durable. Touch screen with wireless control handle, very safe and convenient for operating. |

| Samples made by plastic pe pipe product line |

|

- Q:What are the processes and machines used in the manufacture of plastic products?,

- Processing methods are: injection molding, extrusion, blow molding, blister and so on. Injection molding can be used to produce more complex shapes, such as TV housings. It is the plastic particles in the pre heating tube, and then through the screw under pressure, the melting of raw materials into the mold, cooling molding, the product has been made. Is prepared by continuous extrusion screw drive, which in the feed pipe (commonly known as the barrel) heating plasticization, and then squeeze the stereotypes in the mold, the desired shape, such as plastic buckle, pipes etc.. Blow molding and extrusion are somewhat similar, except that they are placed in compressed air to obtain shapes, such as plastic films, plastic bottles, etc.. Blister is relatively simple, it first made of plastic sheets, baking oven, and then placed in the mold, through the negative pressure to the sheet and mold close to the shape. The price of the equipment varies greatly according to the model and specifications, so it can be checked directly to the manufacturer.

- Q:Plastic blank in the gear hobbing machine processing, hob and workpiece is not to heat, then plastic is not easy to stick on the machine body.Just want to know the plastic gear processing technology is how, and ordinary steel gear processing technology difference where?.The more detailed, the better. Thank you

- This problem, we have the right to speak, first of all, the plastic material relative to steel are quite soft, so the heating problem, processing on hobbing machine, the heat can be ignored, and, in the gear processing machine will have cooling facilities, to cool the workpiece. So this question, Louzhu worry too much.Also, plastic gears, casting molding, but also useful blank after cutting and forming, and this steel and gear is no big process difference......

- Q:Want to buy an injection molding machine to do some plastic products, equipment about how much money ah? What needs to be prepared?

- More than 100 thousand injection molding, about 10-15, model brand difference, tens of thousands of price difference. In addition, supporting facilities, air pump, cooling tower, burr machine and so on nearly 100 thousand, but also procurement of raw materials costs, site costs, pre operation, investment, etc.. If the injection function is installment, then about 250 thousand can start production.

- Q:I am going to work as a worker in a plastics factory. I wonder if the work inside it is very polluting. Is there any harm to the health?

- If you go to a general plastic factory, there will be no pollution. The recycling factory will be a little bigger. It will be very hot in the hot weather, but it will be better in winter

- Q:Is there a difference in melt index before and after processing?

- If no additives are added during processing, the melt index is the same as that before processing.

- Q:Please expert pointing. How high is the profit?. Where are the machines reliable in quality?.

- See how you do, I think Pe high profits, Zhejiang Ruian machine good, thirty thousand or so... We are all over there on the machine... I advise you better not do this, dirty, tired... You can't make much money...

- Q:Is it gear oil or general oil?Inside the old oil is relatively thin, the new gear oil is relatively thick. Can you add?.Please point out.Should we add "ordinary gear oil" or "hyperbolic"?

- Gear oil should be added, and the old one may be flooded or originally not gear oil.Regular is ok.

- Q:Where do engineering plastics processing best?

- Organic glass rods and plates, PTFE rod material, nylon rod, PVC sheet and other mechanical processing performance is good.

- Q:What kind of equipment do we need? How much is the approximate cost? Seek your heroes guidance and guidance!

- Equipment include: film blowing machine, bag machine, punching machine, printing machine, etc., to invest one hundred thousand up and down, but also need a few tons of raw materials as a turnover, and then start production, I do not know very well, just listen to someone else said...

- Q:Which kind of engineering plastics has good processability?

- Organic glass rods and plates, PTFE rod material, nylon rod, PVC sheet and other mechanical processing performance is good.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

double wall corrugated pipe production line high speed big diameter plastic pe pipe product line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords