PLASTIC INJECTION MOLDING MACHINE-N SERIES

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 SET unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Description of PLASTIC INJECTION MOLDING MACHINE-N SERIES

Reliable plastic injection machine with servo motor, equiped with or without servo motor , closed loop control for pressure and flow. Low noise, high precision and energy saving.

We design,manuafcture and supply our own brand of injection molding machine with clamping force ranged from 600kn to 16800kn, injection weight from 80g to 10000g, and also provide custom-built machine.

They can produce all kinds of plastic parts, bottle preform, engineering plastic, UPVC, PVC, PE pipes fitting, components for automotive, household, electronics, telecommunication, ETC

Advantage of PLASTIC INJECTION MOLDING MACHINE-N SERIES

1.ELECTRONLC UNIT

Apply servo control technology to serve energy; Kindly operation interface; Electrical circuit's design meet international security standard; Apply internationally known electrical components; USB data interface

2.HYDRAULIC UNIT

Valve's manufacture use Taiwan technology; Hydraulic circuit's design meet international security standard; Automatic read the oil temperature; Non-welding tubing, reach long reliability and convenient service; Apply internationally known hydraulic comp-onents.

3.INJECTION UNIT

Linear rail movement unit, improve injection precision; High speed hydraulic screw motor; Injection and pressure keeping controlled by closed-loop,precisely control back pressure; Screw barrel use up-detachable structure, change easily; High strength mechanism structure design, assure long term precision.

4.CLAMPING UNIT

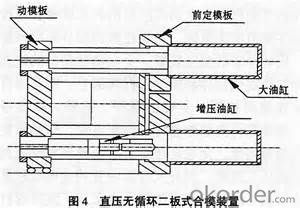

Good repeatability on mold open location; Thick plate, good rigidity, high precision, long life; Scientific toggle mechanism, mold open & close is quick and stable, long life; 4 circuits clear cooling water volume controller; Automatic constant elbow lubrication.

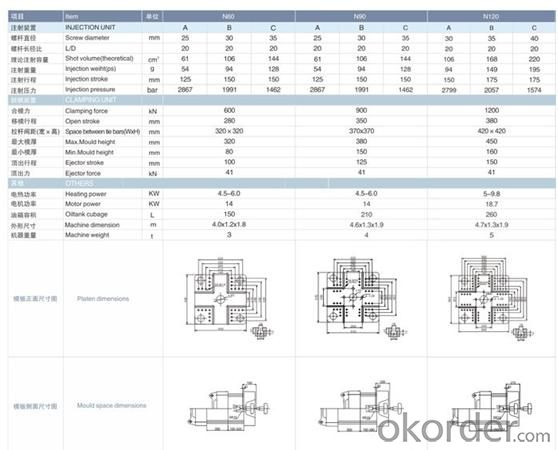

Specification of PLASTIC INJECTION MOLDING MACHINE-N SERIES

Package of PLASTIC INJECTION MOLDING MACHINE-N SERIES

Wooden box packed, suitable for train or sea worthy delivery.

FAQ:

1. Why Choose us?

CNBM is a stated owned company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

3. Can you provide sample?

Yes, we can offer free sample for you.

4. Payment terms?

We can accept L/C, T/T etc.

5. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q:How can we deal with the pollution of waste plastic particles?

- According to the Huacheng machinery senior experts, the current problems like water plastic particles in the machining process can be improved through the method of building see sedimentation tank, water can be reused. The odor problem Huacheng machinery experts tell us, within the industry there is a technique to dispose of smoke and smell. This is a great progress of waste plastics recycling industry.To solve the difficult problem of plastic pollution in the process of granulation, you can be more assured of practitioners engaged in processing. Through investigations now waste plastic particles of the market space is still very great development prospect is good.

- Q:Consult, small toys, plastic products how to shine? What kind of machine or what kind of abrasives do you need? The swordsman knows to ask for help, if feasible, and to have a heavy score! This toy is made of diamond! It's about three or four centimeters in size! Urgent!

- One is to start from the mold and make the inner surface of the mold smooth!One is starting from the material, to make high light products, first of all, there must be good raw materials, and secondly, to have a good stain, high light color powder, to achieve free spraying, high light injection molding, first of all need to use high gloss plastic material.

- Q:Benefits of plastic products

- The advantages of plastics 1. Most of the plastic corrosion resistance is strong, not with acid, alkali reaction. 2, plastic manufacturing costs low. 3, easy to Suzhi into different shapes. 4 is a good insulator. 5, plastic

- Q:How much do you need for it? How about the raw material?

- Good investment in fixed assets and capital flow of fixed assets including site fees, workshop and warehouse and other construction costs, equipment investment (the inquiry to equipment manufacturers), capital flows to see your production scale and product sales capital recovery ability. Specific investment, you can find an expert consulting, I do not understand this line.

- Q:What kind of equipment do you need for the food market? How much would you like to invest? What about the profit?

- if 2 more than 20000 more than 20000 color printing, bag making machine semi-automatic, fully automatic ranging from 4-5 million, 3500 mill more than 20000, granulator, raw materials are polyethylene, if the price of raw materials is a new material price 11000 tons, if it is recycled about 7000 of us production of complete sets of equipment

- Q:The plastic bottle processing plant needs those machines

- Crusher what online, many to transfer technology and plant equipment, you can check for yourself

- Q:I did not come into contact with the plastic design, to understand the mechanical design and traditional design of plastic parts and fittings of the (metal material) are different, from what kind of material, design, drawing standards, labeling etc.. Please engage in plastic design industry heroes pointing!

- The difference between plastic parts design and mechanical design:1: Material: mechanical design is mainly involved in metal materials, plastic is non-metallic, the performance is very different.2, standard: plastic parts with a metal parts of different implementation standards, accuracy is relatively poor, with the relative precision, tolerance range selection is different, marking basically the same, slightly characteristic.3: Connection: plastic parts connection and metal parts connection, compared with its characteristics, generally used: card, buckle connection, insert connection, thread connection, deformation, connection, etc..4 and other: the most important parameters in the design of plastic parts are shrinkage calculation and deformation control, as well as the determination of taper and slope parameters for injection molding.

- Q:Are the fragrance of poisonous substances poisonous in plastic products?

- Poisonous, smelling, and dying so fast, so many people with mechanical hand out, we repair the manufacture of mechanical hand

- Q:this month bought a 180 thousand of the equipment and issued a value-added tax invoices, this sum of money can be deducted? How much deduction?Previously fixed assets are not deductible? Is this a policy that has just been changed this year? What's the tax rate? Thank you!

- Can be deducted from the value-added tax invoices on value-added tax deductible, in addition to the purchase of equipment costs, if there are qualified transport documents, you can also by freight * 7% deduction of input tax

- Q:I would like to ask you how to produce plastic products, the need for mold, but also the need for large machinery, thank you all

- Depending on what you do, different products have different requirements. Plastic products are injection molding, extrusion, injection blowing, extrusion and blowing equipment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PLASTIC INJECTION MOLDING MACHINE-N SERIES

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 SET unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords