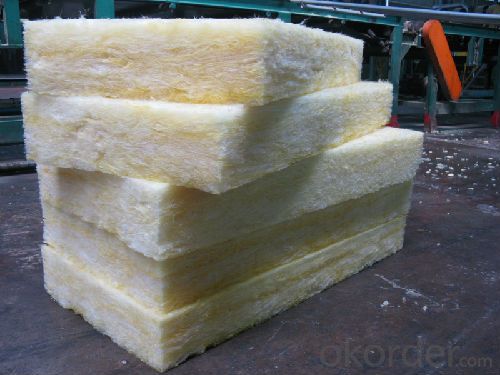

Excellent Quality Glass Wool Blanket Bare For Buildind Thermal Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production Description

Glass wool blanket is in flexible form for ease of installation over large areas. Both products are available to order with a wide range of density and thickness, and with various types of facing applied.

Standard Size

Item | Unit | Index |

Density | Kg/m3 | 10 - 48 |

Thickness | mm | 25-150 |

Width | mm | 1200 |

Length | mm | 5000-30000 |

Remark:

Other sizes available upon request Facing materials can be applied upon request

Technical Data

Item | Unit | Index |

Average Fiber Diameter | μm | 5-7 |

Water Content | % | ≤1 |

Grade of Combustibility | Non-Combustible Grade A | |

Thermal Conductivity ( 25℃) | W/mK | 0.038- 0.045 |

Reshrinking Temp | ℃ | ≥250 |

Hydrophobic | % | ≥98 |

Moisture Rate | % | ≤5 |

Noise Resistant Coefficient (NRC) | 0.75 | |

Slag Inclusion Content | % | ≤0.3 |

Application

Glass Wool are widely used in public, commercial and residential buildings as well as industrial plants, for applications such as roofing, external wall, partition wall and floating floor to provide fire protection, thermal insulation, acoustic control and condensation control.

Material:

Double layers of aluminum foil reinforced with high tensile spring steel wire

Structure: High elastic wire, aluminum foil. A reinforcement model can be required.

Aluminum foil thickness: 0.035mm

- Q:Does anyone know about the specifications of formaldehyde-free glass?wool?boards?

- Different suppliers have different specifications, such as Langfang Juheng Insulation Materials Co., Ltd, their specifications are: unit weight(kg / M) 10-48, thickness (mm) 25-200, length (m) 8-30, Width (mm) 600,1100,1150,1200, etc, and their also provide custom service now.

- Q:There is an engineering air-condition air duct which uses aluminum foil glass wool for heat conservation, supervor require that it should be added a protective layer made by glass fiber cloth. according to peremptory norms,

- Aluminum foil layer itself is a protective layer, which has no need to be increased more protective layers, is using glass cloth for heat conservation layer, you can buy glass fiber cloth without aluminum foil protective layer. However, the protective layer of aluminum foil is really easy to damage, but its impact on air duct is not larger than water pipe, which is acceptable.

- Q:What properties does glass wool felt have?

- Glass wool felt is a formed coiled material aiming to meet the needs of large-scale paving work. Besides its thermal preservation and thermal insualtion functions, it is also equipped with excellent shock absorption and sound absorption and noise absorption for low and medium frequency noise and vibration noise in particular, which is conducive to reducing noise pollution and improving common environment. This material can be cut freely based on needs during construction, which is mainly used as shock insulation, sound absorption and noise supression for interior architecture, muffler system, vehicles, refrigeration equipment and household appliances, and the effect is desirable. Glass wool with aluminum foil veneer has a strong thermal radiation resistance as well, which makes it a superb lining material applied in high temperature workshops, control rooms, inner wall of machine rooms, compartments and flattops.

- Q:What are the differences between the common and high temperature resistant glass wool boards?

- The density of common and high temperature resist boards are different. Boards with higher density are more expensive. It is about 520 yuan per square meter. Nanjing Hairui Insulation Materials Co., Ltd.

- Q:what is the specification of glass wool air duct?

- Generally specifications of glass wool as airconditioner air duct include: 48 k - 30 mm single folder tendons aluminum foil, cost depends on the brand you use, i recommend three good brands to you: Owens Corning/ isover/Shanghai Huali. price is about 400-500 yuan/cubic.

- Q:What are the specific differences between glass wool board and glass fiber board?

- Thus, the full name of glass wool is glass fiber wool: There are two kinds of glass fibers from the uses of fiber glass. The fiber used to weave is the continuous fiber, continuous fiber and staple fiber, and the fiber used to make cotton is staple fiber, glass wool board is equivalent to glass fiber board. You are reminded by the Shouchuang Decoration

- Q:Which is more expensive between glass wool and rock wool?

- Relatively speaking, gass wool is more expensive.

- Q:What performance characteristics does aluminium foil ultra-fine glass wool board have?

- The product is light in volume-weight, low in thermal conductivity, high in acoustical absorption coefficient and good in flame retardation. It can be widely used in thermal equipment, air-conditioning thermostat, hot and cold pipes, drying oven and oast, cold storage and be useds as thermal preservation, thermal insulation, sound insulation and so on for bulidings.

- Q:How is the prospects for rock wool board and glass wool board?

- It is good.Some countries control the use of extruded polystyrene board.Moreover, no new and better energy-saving materials emerge.Therefore, these two materials will be more widely used.

- Q:What's the types of glass wool points? do they have the same sound insulation effect?

- Mineral wool and rock wool basically

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Excellent Quality Glass Wool Blanket Bare For Buildind Thermal Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords