Ductile Iron Check Valve DN200 High Quality and Reasonable Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 set

- Supply Capability:

- 4500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Usage/Applications Of Ductile Iron Check Valve

Check valve is to rely on the flow of the media itself and automatically open, close the valve flap, used to prevent the media back valve, also known as the check valve, Dan Xiangfa, counter flow valve, and back pressure valve. Check valve is an automatic valve, its main role is to prevent the media back, to prevent the pump and drive motor reversal, as well as the release of the container medium.

Technical Date | Material Specification | ||

Nominal Diameter | DN40-DN1000 | Valve Body | Cast Iron or Ductile Iron |

Nominal Pressure | PN10/PN16 | Valve Disc | Cast Iron or Ductile Iron or Stainless Steel |

Operation Temperature | -40°C~225°C | ||

Flange Driling Standard | EN 1902-2 PN10/16 | Seal Material | EPDM OR NBR |

Suface Treatment | Painting | Valve Spring | Stainless Steel |

Quick Details

| Standard or Nonstandard: | Standard | Structure: | Other | Pressure: | Medium Pressure |

| Power: | Hydraulic | Material: | Casting | Temperature of Media: | Normal Temperature |

| Media: | Water | Place of Origin: | China (Mainland) | Model Number: | 34 |

| Brand Name: | CNBM |

- Q:Check valve and check valve

- The name is not the same, there is a check valve, there are video instructions, you can search the "Simon check valve.""

- Q:To prevent water meter rotation, where should the check valve be installed?

- Place it at the top of the water meter, as you can see, near the valve

- Q:What is the reason that the valve is not used for a period of time?Anonymous browsing | 314 times

- 4 the vertical lift check valve shall be mounted on a vertical pipe.5, the lift type horizontal check valve shall be installed on the horizontal pipe.6. Do not check the weight of the valve in the line. The large check valve shall be independently supported so as not to be affected by the pressure caused by the piping system.

- Q:What type of check valve is the h61y-40 check valve?

- Two, swing check valve: the valve swing check valve cylindrical disk-shaped, around the seat of the shaft for rotation channel, because the valve channel into a streamlined, flow resistance than the small valve lift check, suitable for large caliber occasions in low flow and no flow frequently change, but not for the pulsating flow, the sealing performance is less than lift. Swing check valve is divided into single, double, and most types of three, the three forms mainly by the valve bore points, the purpose is to prevent the media to stop flow or reverse flow, weakening the hydraulic impact. Three, compression type check valve: This valve is used as boiler water supply and steam cutting valve, it has lift check valve and stop valve or angle valve comprehensive function. In addition, there are - some do not apply to pump outlet check valve is installed, such as valve, spring-loaded check valve, Y type check valve check valve. Four disc check valve: disc check valve around the pin rotation in the valve seat.

- Q:In the water supply system, water pump and water pump without check valve, a water output to another without pump water pump, effect of rotation, it will cause what kind of damage to the pump?

- For the work of the pump, when stopped, the water will reverse the impact of the blade, resulting in changes in motor power, while the impact will bring air, it is easy to blade cavitation, affecting the life of the pump ah!Like you said, if the two pumps are connected in parallel, another pump reverses, and that's the same thing. Damage doubles. For a high power motor, it doesn't start several times.

- Q:Is the tank stop valve a non-return valve or a check valve?

- The check valve is not the same as the cut-off valve. The difference between them is mainly that the structure is very different.

- Q:What is the HC41X-16Q model of the optical valve? What is its main function?

- The HC41X-16Q check valve for the light valve is a flanged silent check valve.HC41X-16Q flanged check valve features:An acoustic check valve whose structural characteristics allow only medium to flow in one direction and prevent flow in the direction.

- Q:Check valve can not stop water, how to solve?

- Valve is broken, change one, my family is like this

- Q:Check valve H41T-16. What are the numbers and letters in it?

- H stands for check valve, 4 represents flange 1, and represents form 16 for pressure. This is cast iron lift check valve.Check valve refers to rely on the flow of the media itself and automatically open and close the valve flap, used to prevent media backflow valve, also known as check valve, one-way valve, counter flow valve, and back pressure valve. The check valve belongs to an automatic valve, whose main function is to prevent the backflow of medium, prevent the reverse of pump and drive motor, and release the container medium. Check valve (Check Valve): divided by the structure, can be divided into lift check valve, swing check valve and butterfly check valve three. Lift check valve can be divided into vertical and straight through two. Swing check valve is divided into single, double valve and multi flap type of three. Butterfly check butterfly butterfly, double butterfly, butterfly single, more than a few kinds of check valve, in connection form can be divided into thread connection, flange connection, welding and clamp type connection four kinds.

- Q:What are the main types of check valves?

- Two, noun explanation:The opening and closing parts depend on the flow of the medium and the power is turned on or off by itself. The valve that prevents the backflow of the medium is called a check valve. Check valves belong to the automatic valve, mainly used for one-way flow of media channels, allowing only medium to flow in one direction, to prevent accidents.

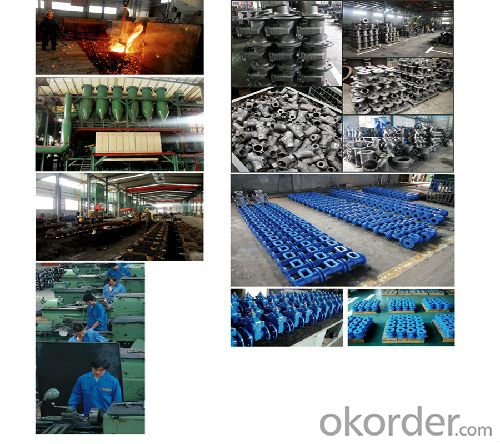

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ductile Iron Check Valve DN200 High Quality and Reasonable Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 set

- Supply Capability:

- 4500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords