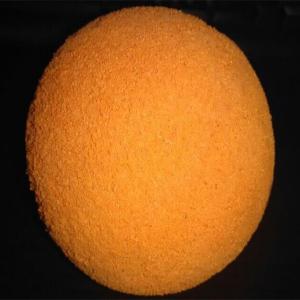

concrete pump pipeline 5'' rubber ball for pipe cleaning

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

concrete pump pipeline 5'' rubber ball for pipe cleaning

SIZE

Cleaning Ball --- DN80, DN100, DN125, DN150

Cleaning Column --- DN125, DN150

STYLE

Cleaning Ball --- hard type, soft type

Cleaning Column --- hard type

FUNCTION

Its main function is used for cleaning concrete pipeline.

PACKING

No.1 Export standard packing

No.2 Seaworthy packing

No.3 other ways or according to the customer demand

Feature

1. It is mainly used for cleaning all kinds of diameter of pump pipe cleaning tool,

maintenance of pipeline cleaning, made channel is more unblocked, unimpeded.

2. Greatly improving the work efficiency.

3. Prolong the service life of the various diameter pipe .

The main products

1. Concrete pump pipe :ST52 concrete pump pipe , 45Mn2 Wear resistant pipes, Twin wall pipes ,Reducer , tee, .ect.

2. the towed concrete pump, Concrete placing boom series.

3. Concrete pump truck fittings : Wear plate and wearring, Svalves, Concrete pump piston , delivery cylinder,.ect

4. Concrete pump clamp : DN80, DN100,DN125,DN150 Casting pipe clamp and Forged clamp.

5. Other accessories: Rubber hose , Cleaning ball , Sponge plug, Seal, The bearing seat, Flange etc.

- Q:What are the reasons for rubber cracking after shock absorption of rubber products?

- The rubber itself is poor in tearing and its products are overloaded.

- Q:What is rubber good for making weapons?

- In the event of war, import and export trade will break, how much a country has a rubber, determines the country can produce a large number of tires and other rubber products, these products will be required for the normal running of the country, when the war came, transport of various materials to manufacture materials, medical aid, in almost every kind of things all the rubber and rubber are inseparable, control, control of the war is almost

- Q:Is it necessary to use rubber products for steel structure buildings?

- Some of the steel structures with small deformation are designed with rubber pads at the sliding bearings.

- Q:Which is better waterproof performance, neoprene or silica gel?

- Silicone rubber (Silicone, rubber), sub heat vulcanizing (high temperature vulcanized silica gel HTV), room temperature vulcanized (RTV), in which room temperature vulcanization type and polycondensation reaction type and additive reaction type.

- Q:Aging of rubber parts for automobiles

- Due to the comprehensive effect of various internal and external factors, rubber products will deteriorate the chemical properties and mechanical properties of this kind of phenomenon is realized by rubber aging, cracking, sticking, hardening, powder, mold. Shute rubber reminder, especially the rubber parts on the vehicle, due to the complex use of the environment, aging accelerated more obvious.

- Q:What is rubber made of?

- High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber. Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life.

- Q:How to enhance the performance of water resistant silicone rubber products

- The purity of the filler and the amount of catalyst residue have great influence on the purity of the filler. In order to improve the steam resistance of silicone products / silicone rubber products, can be used to increase the crosslinking density and the hydrophobic filler method in silica raw material formulation, but should try to avoid the silicone rubber / silicone products using high pressure water vapor over 2MPa under. With this characteristic, the co vulcanizate of siloxane ethylene propylene rubber blends is the best.

- Q:Silicone is silicone rubber? Extracted from there?

- Generally speaking, silica gel can be divided into two categories: organic silica gel and inorganic silica gel according to their properties and components. According to its composition, it is divided into extruded silica gel and molded silica gel.

- Q:How to solve the exhaust problem in rubber vulcanization process

- It is mainly divided into two kinds of natural rubber and synthetic rubber. Natural rubber is made from rubber, rubber and grass. Synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life. It has a wide range of uses. [1] can also be divided into rubber with natural rubber, general rubber, styrene butadiene rubber, nitrile rubber, silicone rubber, butadiene rubber, butyl rubber, EPDM rubber, chloroprene rubber types.

- Q:How to improve the mobility of rubber material

- Fully plasticated rubber use, reduce the Mooney viscosity, improve its ductility.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

concrete pump pipeline 5'' rubber ball for pipe cleaning

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords