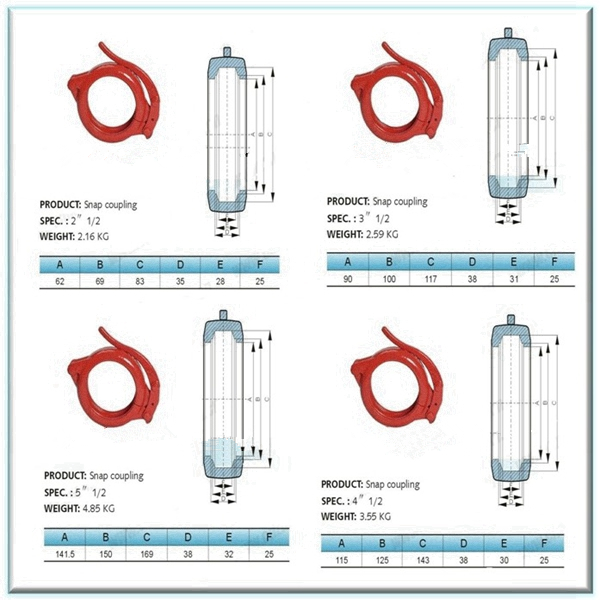

concrete pump pipe connect snap coupling

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product parameters:

Name | Data |

Color | Any |

DN | 125mm |

Technic | Forged or Casting |

Fastening diameter | 125mm |

Style | Fasteners |

Structure | Bolt clamp |

Material | Cast steel |

Standard or Nonstandard | Standard |

Scope of application | concrete machinery/concrete pump pipe |

Specification | |

Φ125 ordinary ( 4 kg ) | |

Tube Card | Φ125 pipe card ( with apron ) |

Tube Card | Φ125 ( including apron ) |

Medium pressure pipe card | Φ125 large nut ( with apron ) |

Medium pressure pipe card | Φ150 pipe card ( with apron ) |

Medium pressure pipe card | Φ150 pressure pipe card ( with apron ) |

Tube Card | Φ175 pressure pipe card ( with apron ) |

Tube Card | Φ180 pressure pipe card ( with apron ) |

Tube Card | Φ200 pressure pipe card ( with apron ) |

Screw pipe clamp | Φ125A |

Screw pipe clamp | Φ125A |

Our advantages:

1. We are a professional manufacturer of concrete pump parts in China, specialized in producing

concrete pump delivery pipe, rubber hose, elbow, bend, reducer, coupling, cleaning ball, piston,

cylinder, eye-glass plate, cutting ring, concrete placing boom, and so on

2. We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA,

KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

Packaging and transport:

No.1 Export standard packing

No.2 Seaworthy packing

No.3 other ways or according to the customer demand

Our services:

1, In case of quality problem the company provide free replacement

2, Provide technical support for free

3, Provide consumers with regular visits

4, Ensure the supply of ancillary parts

5, The company passed the ISO9000 certification, the product through 3 c certification in full compliance with national standards

- Q:does anyone have any ideas for horse party for 10 year old??

- na dude chill out, 6-7 is normal, 5 is the average adult size in america, so your already above the normal, but from what ive read and have been told girls can comfortability hold 8inchs so yea, dont think your small, and your 15 so you might hit 7, 7.5 if your lucky

- Q:The air conditioner outdoor unit tube joint frost even frozen, then the cooling effect is not very good, let people to put the tube for tube, it is flat, then wash the indoor and outdoor unit for good, but after the tube joint is still the same, even frost freezing, refrigeration effect is very poor, cold still cold, but the results are poor, not very cool. Today, I called the master again. He checked and said there was no air leak, then all the gas was drained and the snow was renewed. Later, that tube interface still frosted, I do not want to call the master, and too much water, so many times can not do.I have always stressed and master is not completely open tube valve is not so cold medium to plugging in there, he has not said, I just want to do you need to twist the valve, how to operate, I just want to look at the valve is not open to the maximum torque.

- Find the right size of the six angle wrench, facing the cut-off valve, counterclockwise turn on the valve, clockwise turn off the valve.

- Q:I am building a small rolling road to test my nitro RC cars out and i am trying to figure out the best way to simulate a realistic resisance for the engine and transmission to work againstany ideas?

- This answer is for those who live in Australia. There is an Australian Standard that governs the maintenance of fire extinguishers - AS1851. To comply, you need a tag to record the six monthly checks. Compliance is not necessary in a home situation, only in a commercial environment, or in a strata housing block. The tag is stamped on the month/year it is inspected, with the number 1 through to 5 depending on the nature of the inspection. Local Government enforce the AS1851. An unstamped extinguisher tag might be OK for the first 6 months (if you can prove when you bought it), but it is better if it is stamped, so there is no question that it is compliant. Extinguishers that are older than 5 years must be emptied and pressure tested. Its often cheaper to replace them

- Q:I'm just baught a new LCD TV and i have two wires in each outlet. I want to ground this specific outlet by running a wire to a cold water pipe. What gage wire should i use.

- It That has several preconditions: 1) room to cut the pipe, 2) ability to move one of the cut pipes, 3) already having a repair sleeve, 4) water already shut off. If there is no ability to move either end, then a larger section needs to be cut out and two sleeves installed. This doubles the repair time. For a plumber to do it should be less than 10 minutes unless the pipe is too close. Probably you are in for a minimum service call. Depending on where you are, expect $75 to $200.

- Q:would you think that person was dumb?i got fired today and i dont understand whyi started in june and at first it was hard, i worked at the back making all the burgurs, so it took a while to learn what goes in eachbut i felt i was getting better everytime i went thereand its not like i stole anything, or came late to my shifts, i was there on time everyime i had a shiftdo you think its because i wasnt good at communicating? i stuter a lot and talking to new people is hard, but like i said, i was getting better everytime i came

- try it in real life and use those resources to answer your question.

- Q:I live in a house with an old Gaffers Sattler brand gas furnace/heater. Could this thing be releasing carbon monoxide? My house carbon monoxide detectors have never set off the alarm but perhaps the release from the furnace could be below its threshold. I would appreciate any advice on what situations might exist with the furnace that could produce carbon monoxide and what the solutions might be.

- Yeah, you can get many different types of locks. Locks that can be operated remotely by your cell phone, fingerprint sensitive door locks and many many more. The thing is that these systems will cost you thousands of dollars. I think feeding her cokes is far cheaper than the cost of locking family out. Seems to me like maybe you need to re-examine the family dynamics. Maybe you're going overboard. A cheaper solution might be to get a small fridge, one of those small 5 cubic foot fridges and keep it in your room. You can install a combination lock or a padlock and nobody can get in unless they have the key or know the combination. Otherwise you're going to be spending a TON of money just to protect your cokes. Hope this helps. '')

- Q:I am planning on doing a science project that involves dry ice and the fog that it creates. Will the fog set off smoke alarms? (I can t find any clear answers)

- Maybe they lived in the Montana State University-Billings dorms for a while. The fire alarms would often go off at 3 in the morning on the worst days for weather out of the year, for reasons such as a pipe froze and dripped water on the control panel or a random glitch in the system. This would sometimes happen more than once in a night. It became nearly impossible to take the fire alarm seriously. Especially considering that in the probably 15 or more fire alarm soundings they experienced during the four years I was there, NONE of them were for an actual fire! The closest thing to an actual fire was some burnt toast in the cafeteria. No actual fire, just a thin cloud of smoke and a barely perceivable black circle on the ceiling. I can't say that I really take any fire alarm seriously after that. I take notice when I start seeing smoke.

- Q:is sleeping with a heating blanket every night save?

- pain counsiler the tamer (pick them up on ur shoulders like the f-u but there back facing the other way you flip em and a ddt at the same time

- Q:Can the copper tube use a clip on pipe joint?

- Clip type copper pipe joint;Copper pipe quick joint;Flared copper pipe joint;U type tube joint.

- Q:I use an electric heater in my room, and every time I turn it on, or any electric heater for that matter I get really sick at my stomach and a headache and it's real bad too like reach for the trash can kind of bad. I just feel weird over all. and I almost know it's the heater because I've turned it off and the symptoms disappeared almost immediately (It also got cold really fast too) and I turned it back on same thing. I've tried this with several heaters. but I really have to have something because the outside temp is below zero I believe and this is an old house with poor insulation.and I know I don't have Carbon Monoxide poisoning because I DO have a Gas stove in my bathroom (The old kind too) that I leave burning constantly, but I can sit around that thing all day and not feel any different unless I shut the door for a shower then I might get a little light headed but that only happened to me once and I was in there for a LONG time. plus we have a brand new Carbon Monoxide detector right by it.

- Yes the airflow will be much better my friend

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

concrete pump pipe connect snap coupling

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords