Colored Powder Coated Aluminum Window Extrusions Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

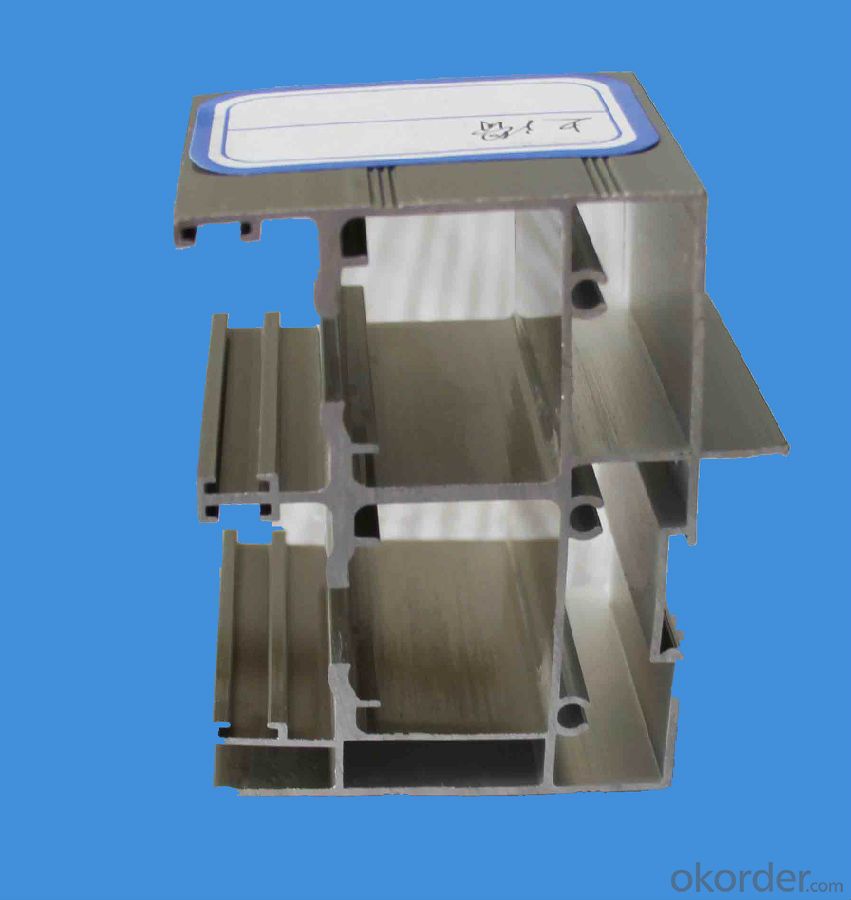

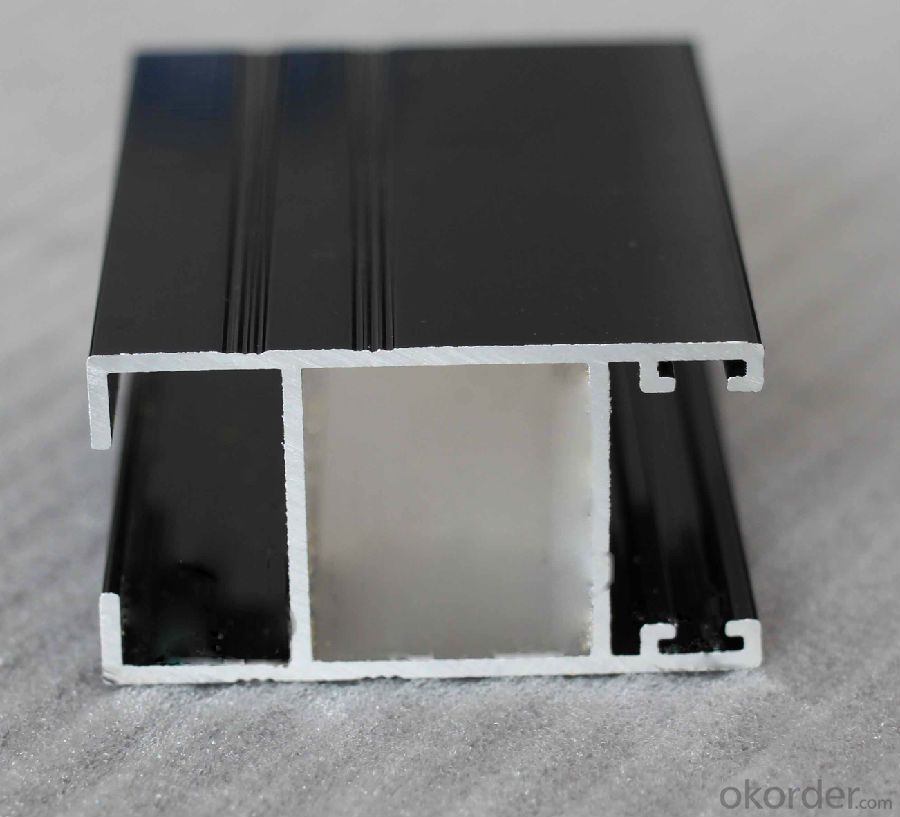

Structure of Colored Powder Coated Aluminum Window Extrusions Profiles Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Colored Powder Coated Aluminum Window Extrusions Profiles:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

Images of the Colored Powder Coated Aluminum Window Extrusions Profiles:

Colored Powder Coated Aluminum Window Extrusions Profiles Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q:Are 101 aluminum sheets suitable for lightweight structural applications?

- 101 aluminum sheets are appropriate for lightweight structural applications. Aluminum is well-known for its lightweight characteristics, making it a popular option for structural applications that prioritize weight reduction. The 101 aluminum alloy is specifically engineered to provide high strength and excellent formability, making it an ideal selection for various structural components. These sheets can be utilized in industries such as aerospace, automotive, and construction, where the emphasis is on reducing weight while maintaining structural integrity. Furthermore, 101 aluminum sheets possess good corrosion resistance, rendering them suitable for outdoor applications or environments with elevated moisture levels. In conclusion, 101 aluminum sheets are a dependable choice for lightweight structural applications due to their strength, formability, and corrosion resistance properties.

- Q:Are aluminum sheets magnetic?

- Aluminum sheets lack magnetic properties and do not exhibit any attraction or interaction with magnets. This is due to the absence of magnetic elements like iron or nickel in aluminum, making it a non-magnetic metal.

- Q:Can 101 aluminum sheets be embossed or textured?

- Yes, 101 aluminum sheets can be embossed or textured. Aluminum is a versatile material that can be easily manipulated and shaped. Embossing or texturing aluminum sheets involves applying pressure or heat to create raised or recessed patterns on the surface. This process can be done with various techniques, such as mechanical embossing or chemical etching. As long as the aluminum sheets are of good quality and thickness, they can be embossed or textured to achieve desired designs and patterns.

- Q:What are the advantages of using aluminum sheets in the packaging industry?

- There are several advantages of using aluminum sheets in the packaging industry. Firstly, aluminum is a lightweight material, making it ideal for packaging applications. It is significantly lighter than other packaging materials such as steel or glass, which makes it easier to handle and transport. The lightweight nature of aluminum sheets also helps reduce shipping costs, as less fuel is required to transport the packaging materials. Secondly, aluminum sheets offer excellent barrier properties. They provide an effective barrier against oxygen, moisture, and light, which are common elements that can deteriorate the quality and freshness of packaged products. This barrier helps extend the shelf life of the packaged goods, ensuring that they reach consumers in optimal condition. Additionally, aluminum sheets are highly durable and resistant to corrosion. This durability ensures that the packaged products remain protected, even in challenging environmental conditions. Aluminum sheets are also resistant to temperature variations, ensuring that the packaging material remains intact and does not warp or deform. Moreover, aluminum is a highly recyclable material. Using aluminum sheets in the packaging industry promotes sustainability and reduces the carbon footprint. Aluminum packaging can be easily recycled and reused, reducing the need for virgin materials and minimizing waste. Furthermore, aluminum sheets offer versatility in terms of design and customization. They can be easily formed and shaped into various packaging formats, such as cans, trays, foils, and pouches. This flexibility allows packaging manufacturers to create innovative and attractive packaging solutions that cater to the specific needs and preferences of different industries and consumers. Overall, the advantages of using aluminum sheets in the packaging industry include its lightweight nature, excellent barrier properties, durability, recyclability, and versatility. These benefits make aluminum sheets a preferred choice for packaging manufacturers, ensuring the protection, preservation, and appeal of packaged products.

- Q:What is aluminium oxide sheet?

- Brief introduction:Advantage:(1) good processing: anodized aluminum decorative strong, moderate hardness, easy bending forming, continuous high-speed, convenient and direct processing into products, no need for complicated surface treatment, greatly shorten the production cycle and reduce production cost.(2) good weather resistance: standard thickness of oxide film (3 m) anodized aluminum plate, indoor use for a long time, no discoloration, no corrosion, no oxidation, no rust. Anodized aluminum oxide film (10 m) can be used outdoors, and can be exposed to sunlight for a long time without discoloration.(3) strong sense: the metal surface of aluminum anodic treatment of high hardness, as gem, scratch resistance, surface is not covered with paint, keep aluminum metal color, highlight the modern sense of metal, improve product quality and added value.(4) high fire resistance: pure metal products, the surface without paint and any chemical substances, 600 degrees high temperature does not burn, does not produce toxic gases, fire protection and environmental protection requirements.(5) strong dirt resistance: no fingerprints, no stain marks, easy cleaning, no corrosion spots.(6) applicability: it is widely used in metal aluminum ceiling, curtain wall board, aluminum plastic panel, fireproof board, honeycomb aluminum plate, aluminum veneer, electrical panel, cabinet panel, furniture panel and so on.

- Q:What are the different types of aluminum sheets available?

- There is a variety of aluminum sheets available, each with its own distinct properties and uses. Some of the most commonly used types are as follows: 1. Pure Aluminum Sheets: These sheets are composed entirely of aluminum and are known for their exceptional resistance to corrosion and high thermal conductivity. They are frequently employed in industries where lightweight and durability are crucial, such as aerospace. 2. Aluminum Alloy Sheets: These sheets are produced by combining aluminum with other elements like magnesium, copper, or zinc, in order to enhance specific properties. For instance, aluminum-magnesium alloy sheets (5000 series) possess remarkable strength and corrosion resistance, making them suitable for marine applications. 3. Painted Aluminum Sheets: These sheets are coated with paint or a protective layer, providing additional defense against corrosion and enhancing their visual appeal. They are commonly utilized in architectural projects and signage. 4. Perforated Aluminum Sheets: These sheets are characterized by evenly spaced small holes or perforations across their surface. They are frequently used in situations where airflow or visibility is required, such as HVAC systems, decorative panels, or speaker grilles. 5. Embossed Aluminum Sheets: These sheets feature a raised pattern or design on their surface, achieved through the process of embossing. This not only adds visual interest but also increases the sheet's strength, making it suitable for flooring, vehicle panels, or decorative purposes. 6. Anodized Aluminum Sheets: This type of aluminum sheet undergoes an electrolytic process known as anodizing, which creates a protective layer on the surface. Anodized sheets exhibit high resistance to corrosion and wear, making them ideal for outdoor applications like building facades, window frames, or automotive trim. Before selecting an aluminum sheet, it is crucial to consider the specific requirements of your project. Factors such as strength, corrosion resistance, appearance, and cost should be taken into account to ensure the most appropriate sheet is chosen for the job.

- Q:The only materials i can use is iodine, water, HCl, magnet, and pH paper. How do you identify aluminum with that?

- To start with, are you refering to aluminum as metal, an aluminum compound, or a solution with aluminum present as ions? If it is metaallic aluminum, it won't stick to a magnet, and it will react with HCl, however this isn't sufficient to definately say it is aluminum, it would be better to get a density, melting point, etc.

- Q:Which is good, aluminum curtain wall?

- Aluminum veneer manufacturers preferred Beijing Jinsheng Aluminium Industry Co. Ltd., it is very important to choose a single aluminum plate manufacturers, Beijing Jinsheng Aluminium Industry Co. Ltd is a professional manufacturer of aluminum veneer, advanced CNC equipment, first-class fluorocarbon spraying line, is your trusted manufacturer of aluminum veneer, aluminum veneer of large manufacturers, advanced technology, advanced technology and to undertake all types of single aluminum plate engineering, quality assurance, price concessions.

- Q:Can 101 aluminum sheets be CNC machined?

- CNC machining is capable of processing 101 aluminum sheets, allowing for the creation of intricate and accurate cuts, holes, and shapes. This versatile and precise manufacturing process is commonly employed for aluminum materials. It involves computer-controlled machines that remove material from the sheets. The CNC machinability of 101 aluminum sheets is not restricted by their specific alloy designation. Nevertheless, to achieve optimal results, it is crucial to take into account factors like cutting parameters, tool selection, and feed rates when machining these sheets.

- Q:Are aluminum sheets suitable for electrical bus bars?

- Yes, aluminum sheets are suitable for electrical bus bars. Aluminum is a lightweight and cost-effective material that exhibits good electrical conductivity. It is commonly used in various electrical applications, including bus bars, due to its ability to efficiently carry high electrical currents while dissipating heat effectively.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Colored Powder Coated Aluminum Window Extrusions Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords