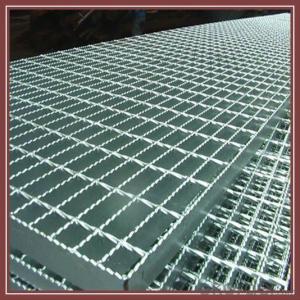

A255/40/100 Aluminum Bar Grating For Deck Access Stair Tread

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Drainage trench cover:

Drainage trench cover is widely used in the urban road, the square, the botanical garden, the wharf, the airport, the parking lot, the road, each kind of industry, the civil project, etc.

2.Main features of Drainage trench cover:

I--Carrying 20 tons of weight

II—Carrying 14 tons of weight

III---carrying 6 tons of weight

IV---carrying 2 tons of weight

V---Carrying pedestrian weight

3.Glass Wool Blanket Images:

4. Drainage Trench Cover Technical Parameters:

These drain cover plate applies to the road cross-sectional and longitudinal drain. The drains width ranging from 200mm to 550mm.

A means the steel grating length

H means the steel grating height

A means the frame length

H means the frame height

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Drainage trench cover is

one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:Okay guys i need to rapir a crack on an aluminum pipe , would durafix do the job ?? If so where can i get this durafix ? at my local home depot ?

- I've only found these type products online or at flea markets. It works quite well after a little practice.

- Q:Whether its strong or not, im looking to get grime like stains out of my aluminum rims. It looks like they can be worked out after time, but i dont think i want to risk acidic products because im not 100% sure if theres a clear coat (i have eagle 077s if that helps!). I have read weird ideas from buffing with baby oil to brake cleaner since its super strong but dont wanna tear up my nice new wheels! Any input is greatly appreciated

- Brake cleaner isnt a bad idea because it is strong and it doesnt have a high acidity level i would give that a shot with a Mother's brand cleaner (personally i think they are the best) with a light scrub brush and a towel to wipe dry i wouldnt spray it down with water i would let the brake clean stick for a few minuets then scrub and lightly rinse, dry then clean with mothers

- Q:Can aluminum sheet be welded?

- Indeed, welding aluminum sheet is feasible. Aluminum, a versatile metal, lends itself well to welding through the utilization of diverse techniques like gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance spot welding (RSW). Nevertheless, the welding of aluminum necessitates specific considerations due to its elevated thermal conductivity and low melting point when compared to other metals. Consequently, selecting the suitable welding process, filler material, and shielding gas is crucial to ensuring a successful weld. Moreover, proper surface preparation, including thorough cleaning and the removal of any oxide layer, plays a pivotal role in achieving a robust and long-lasting weld in aluminum sheet.

- Q:Are aluminum sheets suitable for use in cryogenic environments?

- Yes, aluminum sheets are suitable for use in cryogenic environments. Aluminum has excellent thermal conductivity and low density, making it an ideal material for cryogenic applications. It can withstand extremely low temperatures without losing its structural integrity or experiencing significant thermal expansion. Additionally, aluminum has good corrosion resistance and can be easily fabricated into various shapes and sizes. These properties make aluminum sheets commonly used in cryogenic systems, such as cryostats, superconducting magnets, and liquid nitrogen storage tanks.

- Q:Can aluminum sheets be embossed or engraved?

- Yes, aluminum sheets can be embossed or engraved.

- Q:which kind of abraser should be used for deburring of aluminum sheet?

- you can use soft resin grinding stone.

- Q:How do aluminum sheets compare to steel sheets in terms of strength?

- Aluminum sheets and steel sheets differ in terms of strength. Steel is generally stronger than aluminum, as it has a higher tensile strength, meaning it can withstand greater forces without breaking or deforming. Steel sheets are commonly used in applications that require high strength and durability, such as construction, automotive manufacturing, and aerospace. On the other hand, aluminum sheets offer a good balance between strength and weight. While aluminum is not as strong as steel, it is significantly lighter, which makes it advantageous in certain applications where weight reduction is a priority, such as the manufacturing of aircraft and vehicles. Additionally, aluminum sheets have excellent corrosion resistance, making them suitable for outdoor or marine environments. Ultimately, the choice between aluminum and steel sheets depends on the specific requirements of the application, considering factors like strength, weight, durability, and corrosion resistance.

- Q:What are the standard sizes of aluminum sheets?

- The standard sizes of aluminum sheets vary, but some common dimensions include 4 feet by 8 feet, 4 feet by 10 feet, and 5 feet by 10 feet.

- Q:Can aluminum sheets be polished?

- Yes, aluminum sheets can be polished. Polishing aluminum sheets involves smoothing the surface and creating a reflective finish using abrasive materials or polishing compounds.

- Q:Are 101 aluminum sheets suitable for aircraft manufacturing?

- Indeed, aircraft manufacturing finds 101 aluminum sheets to be a suitable choice. This alloy, commonly utilized in the aerospace sector, possesses a high strength-to-weight ratio, outstanding resistance to corrosion, and remarkable formability. Notably, it is exceptionally fitting for constructing structural elements and skin panels in aircraft production. Moreover, the versatility and efficiency of 101 aluminum sheets are evident in their ease of machining, welding, and joining. Consequently, these sheets are widely employed in aircraft construction, meeting the industry's stringent requirements with great success.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

A255/40/100 Aluminum Bar Grating For Deck Access Stair Tread

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords