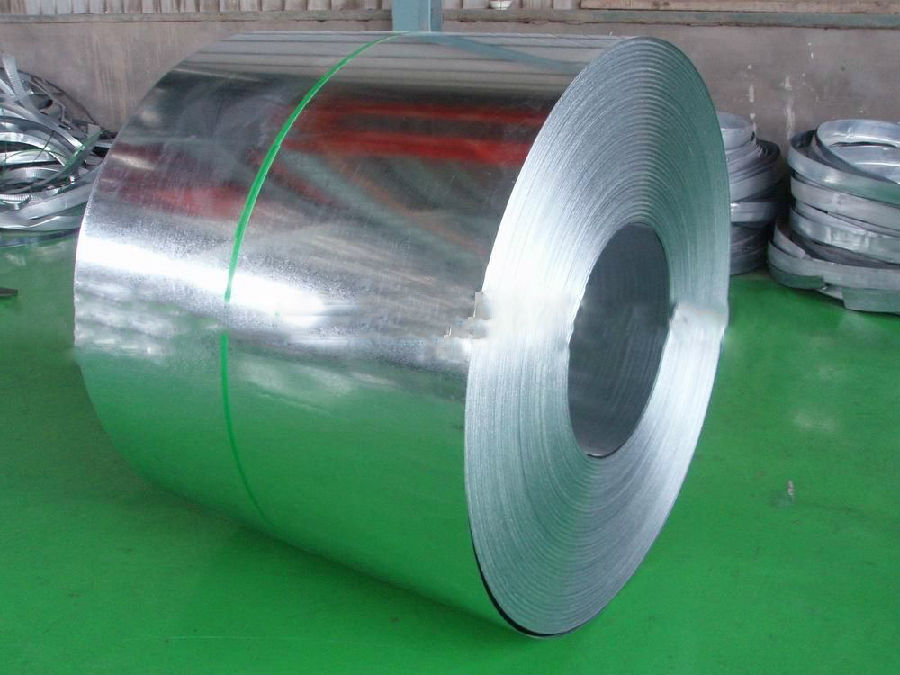

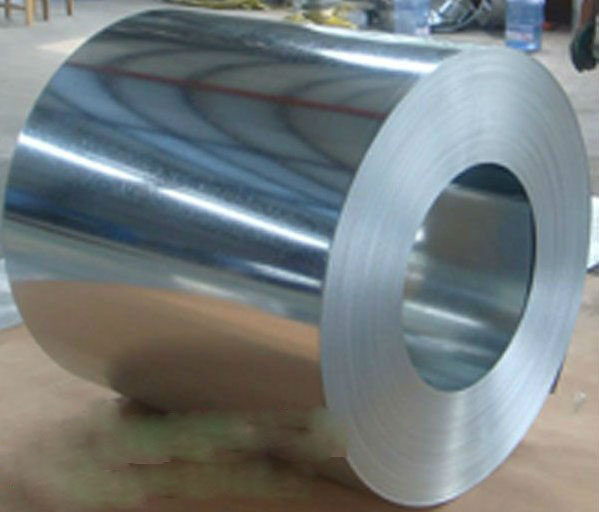

Cold rolled Hot Dip Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2300 PCS

- Supply Capability:

- 230000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Cold rolled Hot Dip Galvanized Steel Coil at great prices with worldwide shipping. Our supplier is a world-class manufacturer of galvanized steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Cold rolled Hot Dip Galvanized Steel Coil is ideal for fabricating and manufacturing applications.

Product Advantages:

OKorder's Galvanized Steel Coil is durable, boasts high stiffness and load-bearing qualities, and is recyclable.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Coil ID: 508mm

Coil OD: 900-1500 mm

Grade: DX51D+Z

Coating: 30 – 180g/m² (both sides)

Dimensions:

Thickness: 0.2mm – 1.0mm

Width: 600mm, 914mm, 1000mm, 1220mm, 1250mm

Coil Weight: 4 – 6mt

Length: 6m, 9m, 12m

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Q6: What is the difference between galvanized steel and Galvalume steel?

A6: Galvanized steel is metallic coated with Zinc in various coating weights. Minimum recommended for painted metal roofs is G90. Galvalume is a zinc and aluminum coated steel that becomes an alloy and is recommended in either painted or bare applications with a minimum coating weight of AZ50. Galvalume has an excellent performance life in bare exposures. Hence if you are using a bare panel use Galvalume and if painted use either.

Images:

- Q:How are steel coils cut to size?

- Steel coils are cut to size using a process called slitting, where the coil is fed through a series of rotating circular blades that make multiple cuts along its length. The blades are spaced at specific distances to achieve the desired width, and the cut strips are then rewound into separate coils.

- Q:How are steel coils used in the manufacturing of automotive hoods?

- Steel coils are used in the manufacturing of automotive hoods as they are shaped and cut into specific dimensions to create the hood's structure. These coils are typically formed into panels through processes like stamping, pressing, and forming, which are necessary to achieve the desired shape and strength.

- Q:How is the quality of steel coils determined?

- The quality of steel coils is determined through various tests and inspections, including visual examination, dimensional inspection, mechanical properties testing, and chemical analysis. These assessments help identify defects, such as surface imperfections, cracks, or variations in thickness and width, as well as ensure the desired mechanical properties and chemical composition of the steel.

- Q:What are the challenges in coil slitting?

- Coil slitting is a process used to cut large coils of metal into narrower strips of desired widths. While it offers several advantages in terms of efficiency and flexibility, there are also several challenges associated with coil slitting. One of the main challenges in coil slitting is ensuring consistent strip width accuracy. Since coil slitting involves cutting the metal coil into smaller strips, it is crucial to maintain consistent width measurements throughout the process. Any deviation in the strip width can lead to issues downstream in the production line, affecting the quality and functionality of the final product. This challenge requires the use of precise slitting equipment and careful monitoring of the process parameters. Another challenge in coil slitting is managing edge quality. The edge quality of the slit strips is critical, especially in applications where the edges need to be free from burrs or other imperfections. Achieving clean and smooth edges requires proper blade selection, positioning, and maintenance. Any defects or irregularities on the strip edges can impact subsequent processes like bending, welding, or coating. Additionally, coil slitting poses challenges related to the material itself. Certain types of metals, such as high-strength steels or alloys, can be more difficult to slit due to their hardness or brittleness. Slitting these materials may result in blade wear and premature failure, leading to increased downtime and maintenance costs. Furthermore, the presence of contaminants or surface defects on the coil can also affect the slitting process, requiring additional cleaning or preparation steps. Another significant challenge in coil slitting is handling and processing large coils. Coils can be heavy and unwieldy, making it crucial to have proper equipment and procedures in place to handle them safely. Additionally, the slitting process can generate significant amounts of scrap material, which needs to be efficiently managed and disposed of. Proper storage, transportation, and recycling of the scrap are essential to minimize waste and maintain a clean and organized working environment. In conclusion, coil slitting offers numerous benefits in terms of customization and productivity. However, it also presents challenges in maintaining strip width accuracy, managing edge quality, dealing with difficult materials, and handling large coils and scrap. Overcoming these challenges requires expertise, precision equipment, and careful process control to ensure the desired quality and efficiency in coil slitting operations.

- Q:How are steel coils tested for flatness and straightness?

- Steel coils are tested for flatness and straightness using various methods such as visual inspection, measurement tools like straightedges or laser devices, and specialized equipment like leveling machines. These tests ensure that the steel coils meet the required standards and are free from any deformities or deviations in their flatness and straightness.

- Q:How are steel coils used in the manufacturing of industrial mixers?

- Steel coils are used in the manufacturing of industrial mixers as they provide a strong and durable structure for the mixer body. The coils are shaped and welded to create the necessary components, such as the mixing chamber and blade supports. This ensures that the mixer can withstand the high forces and vibrations involved in mixing large quantities of materials in industrial applications.

- Q:What are the common coil slitting equipment used in the industry?

- The common coil slitting equipment used in the industry include slitting lines, slitter knives, and tension stands. Slitting lines are machines used to cut a large coil into smaller coils of desired widths. Slitter knives are sharp blades mounted on the slitting line that perform the cutting process. Tension stands are used to control the tension of the coils during the slitting process, ensuring smooth and accurate cuts.

- Q:How are steel coils used in the production of electrical systems?

- Steel coils are used in the production of electrical systems as they provide a crucial component for generating and transmitting electric currents. These coils, made of high-quality steel, are used in a variety of applications such as transformers, motors, generators, and electromagnets. The steel coil's magnetic properties allow it to efficiently conduct and amplify electrical currents, making it an essential component in the overall functioning of electrical systems.

- Q:So, I'm looking into steel toe paddock boots. I'll be using them around horses, horses that I don't know and that are rescue horses. I'm currently looking at Equitector the Moorland paddock boots. They're $200, and I think I have to order them online. I like boots that are this style (the Moorland style)... Is there any other brand of boots that has steel toe paddock boots, that are cheaper or that I can buy in stores?

- I personally know a trainer who is friends with a cowboy who got his toes amputated by a horse stepping on his steel toed boot. I personally prefer a broken toe or a bruised toe. I wouldn't recommend them. If you get your toe stomped and you happen to be standing on pavement or other hardpacked surface...you're going to regret you ever bought them. there's a reason why not a lot of horse people wear them. As for price....$200 is an average price for good boots of any kind. My first western leather boots were Tony Llamas and they were $200. I bought them YEARS ago and they're still just great.

- Q:What does INOX Steel means?I have been looking up the meaning but cannot find it... please help...

- www.okorder /

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cold rolled Hot Dip Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2300 PCS

- Supply Capability:

- 230000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords