Meps Hot Rolled Coil

Meps Hot Rolled Coil Related Searches

Hot Water Bags For Pain Relief Micro Inverter For Solar Panel Stainless Steel Bucket With Lid Hot Water Bottle With Hose Solar Panel With Ac Inverter Solar Panel With Inverter Kit Solar Panel Kits With Inverter Inverter With Solar Panel Aluminum Sheet With Holes Cover Ham With Aluminum FoilHot Searches

Steel Mesh Panels For Sale Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Price Of Shipping Containers For Sale Used Solar Inverter For Sale Portable Led Signs For Sale Stone Hot Water Bottles For Sale Aluminum Coil Stock For Sale Large Led Screens For Sale Aluminum Gutter Coil For Sale Used Aluminum Scaffolding For Sale 1/4 Aluminum Plate For SaleMeps Hot Rolled Coil Supplier & Manufacturer from China

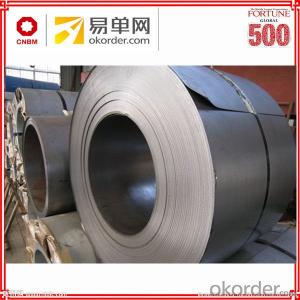

Okorder.com is a professional Meps Hot Rolled Coil supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Meps Hot Rolled Coil firm in China.Hot Products

FAQ

- Steel coils can be packaged in various ways to meet the specific needs and preferences of manufacturers and distributors. Here are some commonly used packaging options: 1. Wooden Crates: To ensure safe transportation and handling, steel coils can be packed in robust wooden crates. These crates, made of durable wood materials like plywood or solid wood, provide excellent protection by securely holding the coils in place. 2. Steel Frames: Another option is to use steel frames, constructed with sturdy steel materials, to firmly secure the coils and prevent any movement or shifting. Steel frames are especially suitable for larger or heavier coils as they offer enhanced stability and durability. 3. Cardboard Boxes: For smaller or lighter steel coils, cardboard boxes can be a suitable choice. These boxes, made of strong and durable cardboard, provide adequate protection against minor impacts and scratches. They are also easy to handle and can be conveniently stacked or stored. 4. Plastic Wrapping: In addition to crates, frames, or boxes, steel coils can be wrapped in plastic materials for added protection. Plastic wrapping safeguards the coils from moisture, dust, and external elements during transportation and storage. This packaging option is commonly used in combination with other methods. 5. Transportation Racks: Specially designed transportation racks made of steel or other robust materials can be used for efficient handling and transport of steel coils. These racks securely hold the coils, allowing for easy loading and unloading, and ensuring enhanced safety during transit. Overall, the choice of packaging for steel coils depends on factors such as size, weight, transportation method, and desired level of protection. Manufacturers and distributors carefully consider these factors to select the most appropriate packaging solution that ensures the safe and efficient handling of steel coils throughout the supply chain.

- Steel coils are essential components in the manufacturing of electrical appliances as they are used to create the core of transformers and electromagnets. These coils, made from steel, provide the necessary magnetic field required for the functioning of electrical appliances such as refrigerators, televisions, and washing machines.

- Steel coils are used in the manufacturing of automotive parts as they are shaped and formed into various components such as body panels, chassis frames, and suspension parts. The coils are processed through a series of steps including cutting, bending, and stamping, to create the desired shape and size for each specific part. These steel components provide strength, durability, and structural integrity to the automobiles, ensuring their safety and performance on the road.

- Certainly, electrical applications can make use of steel coils. In the realm of electrical circuits, steel coils often serve as magnetic cores in transformers and inductors, which are indispensable components. The steel employed in these coils typically consists of high-quality electrical steel, possessing distinct magnetic attributes, including low core losses and high permeability. These attributes empower the steel coils to efficiently transmit electrical energy between various circuit components. Furthermore, steel coils can also find utility in other electrical applications, such as the construction of electric motors and generators. Taking everything into account, steel coils are extensively employed in electrical applications due to their magnetic properties and their capacity to handle high currents and temperatures.

- How are steel tape measures installed?

- The spring piece is fixed on the shaft, the other end is connected with the measuring tape core, fixed tape shell with a shaft, the spring plate and a circle around the axis of the ruler core, wrapped after the ruler core extends from the outer end of the incision length of the shell, gently pull, the spring is tightened, the pull out the part from the incision and then removed around the shaft, then gently pull out, and then put the ruler core tied to the shaft, removed from the incision so repeatedly, until the spring to put all the ruler core recovery. Then a cotter pin on the central shaft installed on the lid, will tighten the screws.

- Is steel with a black coloring as strong as regular steel. if you are asking why i have two wordsBlack Katana.I know a katana is not made with normal steel, it is made of two types with varying grades of carbon to give it speacial properties, i just want to know if the black will make a difference.

- There are many types of steel some very rigid, while you can have steel that is very flexible. The type of katana: steel is for Samurai swords

- Steel coils are used in the production of steel brackets by being processed and cut into the desired shape and size. The coils serve as the primary raw material, providing the necessary strength and durability for the brackets.

- nan

- Steel framing replaces all the wood making the house stronger and resistant to termites. Costs about $2,000 more per house and there is a lack of trained framers in most cities. Never heard of Kodiak brand. Do you know a city where they are located?