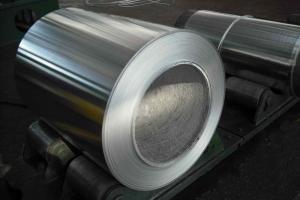

3003 H14 H22 Aluminum Coil Manufacturers

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Aluminum coil manufacturers

Temper: O H12/ H14/24 H16/26 H18 H19

Thickness: 0.20-3.0mm

Width: 16-1600mm

Usage: capacitor strip, aluminum plastic composite material, car parts, building decoration materials, stamping products, building mirror materials, nameplate, insulation materials, container package, welding parts, clock surface and disk, kitchen utensils, reflecting apparatus etc.

Application

Machine,auto, can, building, ship and so on.

Packaging & Shipping

Standard export seaworthy package or as cilents' requirement

Company Information

Through the years, we have built many modern production lines, including one 1+2 hot rolling production line, six 2,450, 2,050, 1,650 and 1,450mm cold rolling lines, two 1,650mm foil rolling production lines, two 1,850mm continuous rolling production lines and one roll coating production line. Besides, we also bring in 8 x 20 annealing furnaces, tension leveled machines, tension pre-stretch machines, cutting machines, cleaning equipment, testing machines and packing equipment from at home and abroad to be able to complete various clients' requirements

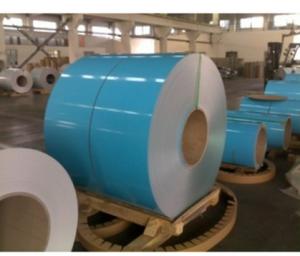

Colored aluminum sheet polyester coating is a UV protection coating; the polyester resin is the use of the main polymer chain of ester bond-containing monomer, adding an alkyd resin, an ultraviolet absorber and can be divided according to the glossiness matt and high-gloss series, especially for interior decoration and advertising boards.

Fluorocarbon colored aluminum sheet is fluorine eneyne fluorocarbon resin basic monomer, a pigment, ester solvents, additives, mixed together. After high temperature barbecue deposition, the molecular structure of the coating becomes tight, with superior weather resistance. According fluorocarbon coating film on the surface structure can be divided into two kinds of conventional fluorocarbon coating fluorocarbon nano. Especially suitable for public places, indoor and outdoor decoration, commercial chains, exhibition and display advertising and other decorative colored aluminum sheet

- Q:A bit of a question for the 1911 experts roaming around here. Per-say someone, who knew their way around a 1911 built one on an aluminum frame. To top it all off, if the finished gun were to be chambered in .38 super... how long would this combination last? I've heard horror stories about aluminum frames, and then I've heard some wonderful things... this question was to see if anyone had ever thought about/done this sort of thing before. Something tells me that Aluminum + .38 super wouldn't last too long... Most informative answer gets the ten point prize as usual.

- I have two concerns about using an aluminum frame for that caliber. First, and like everyone else who answered, I don't think it will stand up to the .38 Super +P for very long (and I wouldn't want to be around when it fails). Second, the reason I believe the frame will not last nearly as long as a steel or stainless (my personal suggestion) frame is that the grooves the slide fits and rides in will wear and enlarge MUCH faster than a steel or stainless frame will. This will, in my opinion, also quickly have an adverse affect on accuracy. Aluminum has it's place, but I don't think it's anywhere near this kind of firearm. On a side note, one of the other people who answered said that the aluminum will offer some corrosion resistance. This may generally be true, but salt water (like sweat) attacks aluminum significantly faster than it does steel, and stainless steel is almost non-reactive to it. If he wants a lighter gun for carry, Try an XD45. If I remember right they are rated for .45 +P, but call Springfield Armory to make sure. With the polymer frame they are much lighter than a 1911, and I have been very satisfied with the accuracy and the reliability of mine. Personally, I don't think the weight savings of the alloy frame is worth the extra care to keep from sweating on it or the much shorter lifespan the gun will likely have. If he isn't planning on carrying it, what is the point of lightening the gun? He'll feel a lot more recoil, especially if he does shoot the +P ammo.

- Q:Can aluminum coils be painted or coated for aesthetic purposes?

- Yes, aluminum coils can be painted or coated for aesthetic purposes. Aluminum is a versatile material that can be easily painted or coated to enhance its appearance. Painting or coating aluminum coils can provide a wide range of color options and finishes, allowing for customization and aesthetic appeal in various applications. The paint or coating can also provide additional protection against corrosion and weathering, increasing the durability and longevity of the aluminum coils. However, it is important to select the appropriate type of paint or coating that is compatible with aluminum and suitable for the intended use to ensure optimal results.

- Q:What are the maintenance requirements for aluminum coils?

- The maintenance requirements for aluminum coils typically involve regular cleaning to remove dirt and debris, inspection for any signs of corrosion or damage, and ensuring proper airflow around the coils to prevent overheating. Additionally, periodic lubrication of moving parts and regular filter replacement are recommended to maintain optimal performance and efficiency.

- Q:What are the typical mechanical properties of aluminum coils?

- The mechanical properties of aluminum coils may differ depending on the specific alloy and temper of the material. However, aluminum coils typically possess the following mechanical properties: 1. Tensile strength: Aluminum coils generally demonstrate a high tensile strength, which refers to the maximum amount of tensile stress a material can endure before breaking. This property is crucial for applications that require the material to withstand heavy loads or stress. 2. Yield strength: Yield strength represents the stress threshold that a material can bear without undergoing permanent deformation. Aluminum coils typically possess a relatively high yield strength, enabling them to maintain their shape and structural integrity under normal operating conditions. 3. Elongation: Elongation refers to the extent to which a material can stretch or deform before fracturing. Aluminum coils usually exhibit a relatively high elongation, making them suitable for applications that involve forming or bending without breaking. 4. Hardness: The hardness of aluminum coils may vary depending on the alloy and temper. Aluminum alloys can undergo heat treatment to enhance their hardness, rendering them more suitable for applications that demand wear resistance or the ability to withstand harsh environments. 5. Fatigue strength: Fatigue strength denotes a material's capacity to resist the formation and growth of cracks under cyclic loading conditions. Aluminum coils generally exhibit good fatigue strength, making them suitable for applications subjected to repeated or fluctuating loads. It is important to note that these properties can vary depending on the specific alloy, temper, and processing conditions of the aluminum coils. Therefore, it is advisable to refer to the material specifications or contact the manufacturer for more precise and detailed information regarding the mechanical properties of specific aluminum coils.

- Q:I have completely disassembled my aluminum bass boat and it is being sandblasted.I am restoring the boat and will be giving it a new paint job.What do you recommend in the way of primer,paint or anything else I need to know.I just don,t want to mess it up by using the wrong thing.Best answer gets a fishing trip in the same boat we are talking about. If you can make it here I will put you on some fish.Catfish,bream,crappie,bass or even saltwater fish.

- Contact the manufacture and see what they used as it held up for quite a few yrs. Primer for aluminum is the beginning.

- Q:What are the potential applications of coil-coated aluminum coils?

- Coil-coated aluminum coils have a wide range of potential applications due to their versatility and durability. Some common applications include roofing and cladding for buildings, automotive parts, signage, electronics, and appliances. The coil coating process enhances the aluminum's resistance to corrosion, weathering, and fading, making it suitable for both indoor and outdoor uses. Additionally, the ability to apply various colors and finishes to the coils allows for customization and aesthetic appeal in different industries.

- Q:Are aluminum coils suitable for architectural façade systems?

- Yes, aluminum coils are suitable for architectural façade systems. Aluminum is a highly versatile and durable material that can be easily shaped and manipulated to meet the specific design requirements of a building's façade. It is lightweight, corrosion-resistant, and can withstand harsh weather conditions, making it an ideal choice for long-lasting exterior applications. Additionally, aluminum coils can be coated with various finishes, such as paint or anodizing, to enhance their aesthetic appeal and provide additional protection against fading or chipping. The flexibility and versatility of aluminum coils make them an excellent option for architectural façade systems, allowing for creative and unique designs while maintaining durability and performance.

- Q:does anyone know any ANTI-PERSPIRANTS that don't have any harmful chemicals such as aluminum chloride? I need something that makes you not sweat but I don't want bad chemicals in it!

- This Site Might Help You. RE: Anti-perspirant without aluminum chloride? does anyone know any ANTI-PERSPIRANTS that don't have any harmful chemicals such as aluminum chloride? I need something that makes you not sweat but I don't want bad chemicals in it!

- Q:What are the precautions to be taken while handling aluminum coils?

- Some precautions to be taken while handling aluminum coils include wearing protective gloves to prevent cuts or injuries, using proper lifting techniques to avoid strain or back injuries, storing coils in a dry and well-ventilated area to prevent corrosion, using appropriate equipment and tools for handling and transportation, and following safety guidelines provided by the manufacturer. It is also important to be aware of the weight and balance of the coils to prevent accidents or damage.

- Q:What are the different mechanical properties of aluminum coils?

- The different mechanical properties of aluminum coils include high strength, excellent formability, good corrosion resistance, and low density.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

3003 H14 H22 Aluminum Coil Manufacturers

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords