Steel Rolled Coil Hot Rolled Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Steel Rolled Coil Hot Rolled Steel Coils

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Steel Rolled Coil Hot Rolled Steel Coils

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Steel Rolled Coil Hot Rolled Steel Coils

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

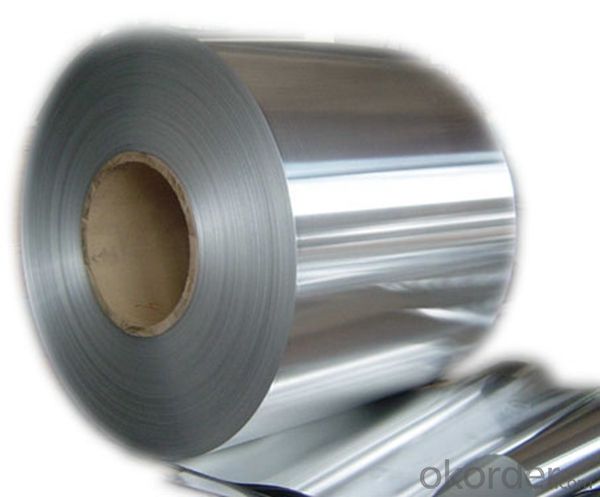

5. Image of Steel Rolled Coil Hot Rolled Steel Coils

6. Package and shipping of Steel Rolled Coil Hot Rolled Steel Coils

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Can aluminum sheets be used for curtain walls?

- Yes, aluminum sheets can be used for curtain walls. Aluminum is a popular choice for curtain wall systems due to its lightweight nature, durability, and corrosion resistance. Aluminum sheets can be easily formed into various shapes and sizes, making them suitable for creating the structural frame of curtain walls. Additionally, aluminum can be coated or anodized to enhance its aesthetic appeal and provide additional protection against weather elements. This makes aluminum sheets a versatile and practical material for constructing curtain walls in commercial and residential buildings.

- Q:Can aluminum sheets be embossed or textured?

- Yes, aluminum sheets can be embossed or textured using various methods such as roll embossing or mechanical texturing.

- Q:Are aluminum sheets easy to work with?

- Yes, aluminum sheets are generally easy to work with. Aluminum is a lightweight and malleable metal, which makes it easier to cut, shape, and manipulate compared to other metals. It can be easily bent, formed, and welded, allowing for various fabrication techniques. Additionally, aluminum sheets have good corrosion resistance, which further adds to their ease of use. Whether it is for constructing lightweight structures, fabricating parts, or creating intricate designs, aluminum sheets provide versatility and convenience in many applications.

- Q:Are aluminum sheets suitable for outdoor applications?

- Yes, aluminum sheets are suitable for outdoor applications. Aluminum is a highly durable and corrosion-resistant material, making it ideal for use in outdoor environments. It can withstand exposure to various weather conditions, including rain, snow, and sunlight, without deteriorating or losing its structural integrity. Additionally, aluminum sheets can be coated or painted to enhance their resistance to fading, scratching, and other forms of wear and tear. This makes them perfect for outdoor applications such as roofing, siding, signage, and decorative elements. Moreover, aluminum is lightweight and easily malleable, allowing for easy installation and customization. Overall, aluminum sheets are a reliable and long-lasting choice for outdoor projects.

- Q:Are aluminum sheets suitable for high-temperature applications?

- Aluminum sheets are generally not suitable for high-temperature applications. While aluminum has a relatively high melting point of 660.3°C (1220.5°F), its strength and mechanical properties significantly decrease as the temperature rises. At elevated temperatures, aluminum tends to soften, deform, and lose its structural integrity. Additionally, aluminum has a relatively low thermal conductivity, which means it does not efficiently conduct heat away from the source, leading to potential overheating issues. Therefore, for high-temperature applications, materials such as stainless steel or refractory metals like titanium or tungsten are more commonly used due to their superior high-temperature performance and thermal conductivity.

- Q:Can aluminum sheets be formed into seamless tubes or pipes?

- Yes, aluminum sheets can be formed into seamless tubes or pipes through a process called extrusion.

- Q:What is the corrosion resistance of aluminum sheets?

- Aluminum sheets have excellent corrosion resistance. Aluminum naturally forms a protective oxide layer on its surface when exposed to oxygen, which acts as a barrier against corrosion. This oxide layer is very stable and prevents further oxidation of the metal, making aluminum highly resistant to corrosion in most environments. Additionally, aluminum sheets can be further enhanced with surface treatments or coatings to increase their corrosion resistance even more. This makes aluminum sheets a popular choice for various applications where corrosion resistance is crucial, such as in the construction industry, automotive manufacturing, and marine applications.

- Q:why is copper sheet but not aluminum sheet that becomes the negative pole after putting copper sheet and aluminum sheet connected with wire into concentrated nitric acid?

- According to metal reactivity series order table, aluminum has a better metallicity, but it will be passivated soon after contacting concentrated sulfuric acid, and won’t react again. But copper and concentrated sulfuric acid can react continually. So aluminum sheet becomes the positive pole after passivation.

- Q:What does aluminum plate "3003-H24" mean?

- According to the main alloy aluminum alloy elements can be divided into 2 * * * for Al Cu alloy aluminum (Al--Cu), 3 * * * aluminum manganese alloy aluminum (Al--Mn), 4 * * * series of aluminum silicon alloy aluminum (Al--Si), 5 * * * for aluminium magnesium alloy aluminum (Al--Mg). 6 * * * for Al Mg Si alloy aluminum (AL--Mg--Si), 7 * * * for aluminum and zinc alloy aluminum [AL--Zn--Mg-- (Cu)].Aluminum status: 1, F: free machining status. 2 and O: annealed condition 3 and H: work hardening state. 4, W: solid solution heat treatment state. 5, T: heat treatment state.

- Q:Carbon costs more than aluminum. But there are manufactures who make high quality alloy frames which costs just as much, if not more slightly than mediocre carbon frames.In your opinion, which is better, stiffer, and lighter?If you need examples....umm like Cervelo's S1 or CAAD9 compared to the lower quality carbon frames.

- A combo of both is nice. But if I had the choice, I would go stiffer frame (aluminum) with carbon stays. For a carbon frame, the carbon has to be decent quality, not like the carbon that is used for making Raleigh frames. Low quality!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Rolled Coil Hot Rolled Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords