Steel Rolled Coil Q345 Q195 Hot Rolled Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description:

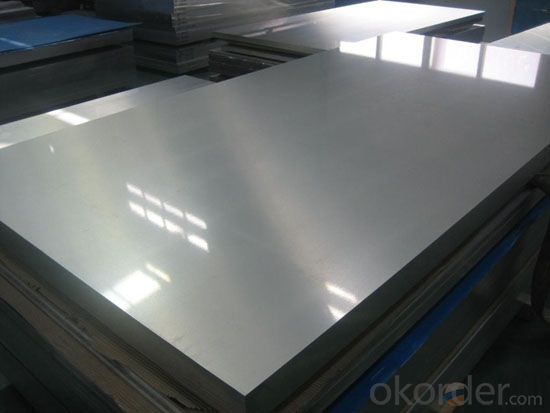

General Information of Cold Rolled Steel Sheet

The raw material of cold rolled steel sheet is high quality hot rolled product, and after pickling, continuous rolling, degreasing, annealing, skin pass, slitting and cut to length line etc. Along with it many kinds of new technology and new process of global cold rolling production have been applied. Therefore the quality of the goods could be guaranteed. The finished product has a variety of excellent capabilities, such as processing capability and smooth, flat surface. It’s widely used in outdoor and interior decoration, furnishing manufacturing, home appliance, automobile etc.

Specifications of Cold Rolled Steel Sheet

1) Grade: SPCC, SPCD, SPCE, DC01-06, St12, Super deep drawing

2) Standard: JIS G3141-1996, EN 10131-2006, DIN EN 1002

3) Thickness: 0.20mm - 3.0mm

4) Width: 600/1000/1250/1500 (mm) or per customer's request

Package of Cold Rolled Steel Sheet

Strapped with min three strapping strips, covered by anti-water paper and plastic film, fixed on the iron or wooden pallets by strapping strips and covered by plastic bag to prevent damage from transportation.

Applications of Cold Rolled Steel Sheet

1) For the further producing of hot dip galvanized steel products

2) Cold rolled Steel: Auto manufacture, Oil drum, Transformer's tank panel, Furniture etc.

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q:What is the cost of an aluminum sheet?

- The price of an aluminum sheet can change due to various factors, including thickness, size, grade, and market conditions. Typically, aluminum sheets are priced based on square footage or weight. On average, the price can vary from $0.50 to $5 per square foot or $1 to $10 per pound. It is crucial to understand that these figures are approximate and subject to change based on factors such as supply and demand, location, and others. To obtain an accurate cost, it is advisable to reach out to local suppliers or explore online marketplaces for the latest pricing information.

- Q:How does the purity of aluminum affect its properties as a sheet?

- The purity of aluminum greatly affects its properties as a sheet. Higher purity levels result in increased strength, improved corrosion resistance, and enhanced conductivity. Pure aluminum sheets are softer and more malleable, making them easier to form and shape. However, impurities can negatively impact these properties, reducing strength and increasing susceptibility to corrosion. Therefore, maintaining high purity levels is essential for achieving desired sheet properties and performance.

- Q:Are aluminum sheets resistant to chemicals?

- Yes, aluminum sheets are generally resistant to a wide range of chemicals.

- Q:Can 101 aluminum sheets be used in aerospace applications?

- Yes, 101 aluminum sheets can be used in aerospace applications. 101 aluminum is a commonly used alloy in the aerospace industry due to its excellent strength-to-weight ratio, high corrosion resistance, and good formability. It is often used for structural components, such as aircraft skins, wings, and fuselage panels. Additionally, 101 aluminum sheets can be easily machined and welded, making them ideal for aerospace applications where precision and durability are crucial.

- Q:What are the different forming techniques for aluminum sheets?

- Aluminum sheets can be shaped using several different forming techniques. One technique commonly used is bending, where force is applied to the sheet to achieve the desired shape. This can be done manually with a press brake or through automated processes like roll forming or stretch forming. Another technique, called deep drawing, involves using a die and punch to stretch the aluminum sheet into a three-dimensional shape. This method is often employed to create cylindrical or box-shaped components such as cans or containers. Hydroforming is another option for shaping aluminum sheets. It utilizes hydraulic pressure to mold the sheet against a form or mold. This technique is particularly useful for creating complex and irregular shapes that would be challenging to achieve with other methods. For creating symmetrical shapes like bowls or cones, spinning is a commonly used technique. It entails rotating the aluminum sheet against a mandrel while applying pressure to shape it into the desired form. Lastly, there is a technique known as stamping, which involves pressing the aluminum sheet against a die to create a specific shape. This technique is frequently employed in high-volume production of components such as automotive body panels. In conclusion, these forming techniques provide a wide range of options for shaping aluminum sheets into various forms and designs. This allows for flexibility and versatility in manufacturing processes.

- Q:Why must the aluminum oxide be electrolyzed in a molten cryolite solution?

- To electrolyse aluminium oxide, it has to be molten. However, the melting point of Al2O3 is extremely high ( 1000°C), and that would make the electrolysis very inefficient. However, Al2O3 dissolves in cryolite at much lower temperatures (lower than 900°C), which makes it a much more viable process.

- Q:im doing a science project on aluminum and i need to know if aluminum is combustible or not. I was reading a website and they said that it reacts when its the right temperature? i really have no idea what the answer is please help! :)

- Aluminum metal oxidizes readily in air but when that happens, a layer of aluminum oxide will form, preventing further oxidation. So if you have a block of aluminum, the surface will oxidize and the rest will not. If you shave aluminum into a fine powder, you can actually light it on fire as it will rapidly and violently oxidize because there is more surface area. If you add iron powder in the mix, it will burn even hotter. I would not recommend doing this reaction.

- Q:doesn't particularly need to be welding but i need to make an air tight permanent seal around 2 very thin sheets of aluminium (like .02 inches thick) i was thinking .02 inch 5052 aluminum because its the thinnest i can find but am obviously up for suggestions.

- TIG okorder /

- Q:Can the aluminum sheets be used for architectural cladding?

- Indeed, architectural cladding can make use of aluminum sheets. Owing to its lightweight properties, durability, and versatility, aluminum remains a favored selection for cladding purposes. Its pliability and ability to assume diverse forms make it ideal for a broad spectrum of architectural designs. Furthermore, aluminum boasts corrosion resistance, ensuring its longevity as a cladding option. Moreover, the possibility of coating aluminum in various finishes enables customization to align with the desired aesthetic of the structure. All things considered, aluminum sheets emerge as a dependable and pragmatic choice for architectural cladding.

- Q:Can 101 aluminum sheets be welded?

- Yes, 101 aluminum sheets can be welded. Aluminum, including 101 aluminum alloy, is commonly used in welding due to its excellent weldability. It is important to note that proper welding techniques and equipment should be used to ensure a successful weld.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Rolled Coil Q345 Q195 Hot Rolled Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords