All Categories

- - Steel Wire Rod

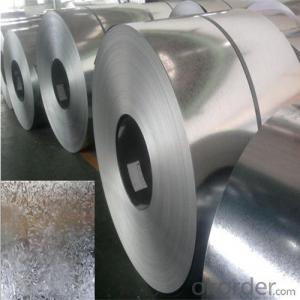

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What measures are in place to prevent coil contamination during the production of medical equipment and devices?

In order to prevent coil contamination during the production of medical equipment and devices, several measures are in place. Firstly, manufacturers follow strict cleanliness protocols in their production facilities. This includes maintaining clean and controlled environments, such as sterile rooms or cleanrooms, where the equipment is assembled and packaged.

Additionally, manufacturers employ rigorous quality control procedures to ensure that all components, including coils, meet the required cleanliness standards. This involves thorough inspections and testing at various stages of the production process. Any contaminated or faulty coils are promptly identified and removed from the production line.

Furthermore, manufacturers implement proper handling and storage practices to prevent contamination. Coils are typically stored in sealed packaging or containers, ensuring they are protected from dust, particles, and other potential contaminants until they are ready for use.

Overall, these measures aim to maintain the highest level of cleanliness and ensure that the coils used in medical equipment and devices are free from any potential sources of contamination, thus upholding the safety and effectiveness of the final products.

How are steel coils used in the construction of infrastructure and buildings?

Steel coils are used in the construction of infrastructure and buildings in various ways. They are commonly used for manufacturing structural components such as beams, columns, and trusses, which provide strength and support to the overall structure. Steel coils are also used for producing rebar, which is essential for reinforcing concrete structures like foundations, walls, and floors. Additionally, steel coils can be formed into roofing and siding materials, offering durability and protection against harsh weather conditions. Overall, steel coils play a vital role in enhancing the stability, longevity, and resilience of infrastructure and buildings.

How are steel coils tested for chemical composition and purity?

Steel coils are tested for chemical composition and purity through a process called spectroscopy. This involves using specialized instruments to analyze the elemental composition of the steel samples. Additionally, various techniques such as X-ray fluorescence (XRF) and optical emission spectroscopy (OES) are utilized to determine the presence and levels of impurities in the steel coils.

Wholesale Steel Coils from supplier in Honduras

Whether you are in need of hot-rolled steel coils, cold-rolled steel coils, or galvanized steel coils, we have the capacity to meet your requirements. Our steel coils are sourced from reputable manufacturers and undergo strict quality control measures to ensure that they meet international standards.

In addition to supplying steel coils, we also offer value-added services such as slitting, shearing, and packaging to meet your specific needs. Our team of experts is available to provide technical support and guidance throughout your project, ensuring that you receive the most suitable products for your applications.

With our strong global network and logistics capabilities, we can efficiently deliver steel coils to any location in Honduras. Whether you are in the construction, automotive, or manufacturing industry, we have the knowledge and resources to support your operations.

At CNBM, we prioritize customer satisfaction and strive to build long-term partnerships with our clients. Our dedicated sales team is committed to providing prompt and reliable services, including timely quotations and competitive pricing. We understand the importance of meeting deadlines and ensuring that your projects run smoothly.

Choose us as your trusted supplier of steel coils in Honduras and experience the benefits of working with a reputable and reliable company. Contact us today to discuss your requirements and let us assist you in finding the best steel coil solutions for your business.

In addition to supplying steel coils, we also offer value-added services such as slitting, shearing, and packaging to meet your specific needs. Our team of experts is available to provide technical support and guidance throughout your project, ensuring that you receive the most suitable products for your applications.

With our strong global network and logistics capabilities, we can efficiently deliver steel coils to any location in Honduras. Whether you are in the construction, automotive, or manufacturing industry, we have the knowledge and resources to support your operations.

At CNBM, we prioritize customer satisfaction and strive to build long-term partnerships with our clients. Our dedicated sales team is committed to providing prompt and reliable services, including timely quotations and competitive pricing. We understand the importance of meeting deadlines and ensuring that your projects run smoothly.

Choose us as your trusted supplier of steel coils in Honduras and experience the benefits of working with a reputable and reliable company. Contact us today to discuss your requirements and let us assist you in finding the best steel coil solutions for your business.