All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

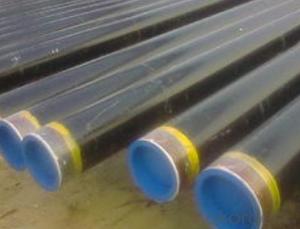

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the implications of fluid hammer in steel pipelines, and how can it be mitigated?

Fluid hammer in steel pipelines can have several implications. Firstly, it can cause significant damage to the pipeline itself, leading to leaks or even ruptures. This can result in costly repairs and potential environmental hazards. Secondly, fluid hammer can also cause damage to connected equipment and infrastructure, such as pumps, valves, and fittings.

To mitigate fluid hammer in steel pipelines, several measures can be taken. One approach is to install surge relief devices, such as surge tanks or pressure relief valves, which help to absorb and dissipate the excess pressure caused by fluid hammer. Additionally, properly sizing and designing the pipeline system, including the use of appropriate pipe materials and thickness, can help to minimize the occurrence of fluid hammer. Lastly, implementing control strategies, such as gradual valve closures or the use of check valves, can help to reduce the sudden changes in flow velocity that often contribute to fluid hammer. Overall, a combination of engineering design, appropriate equipment selection, and operational practices can effectively mitigate the implications of fluid hammer in steel pipelines.

How are steel pipes used in the automotive industry for fuel delivery and exhaust systems?

Steel pipes are used in the automotive industry for fuel delivery and exhaust systems due to their durability, corrosion resistance, and high heat tolerance. They are commonly used to transport fuel from the tank to the engine, ensuring efficient and safe fuel delivery. Additionally, steel pipes are ideal for exhaust systems as they can withstand the high temperatures and harsh conditions produced by the combustion process, effectively channeling the exhaust gases away from the engine.

How are steel pipes integrated into the construction of bridges and other infrastructure projects?

Steel pipes are commonly used in the construction of bridges and other infrastructure projects for various purposes. They are integrated by being incorporated into the structural framework, providing support and stability. Steel pipes can be used for piling, forming the foundation of the structure, or as columns and beams, carrying the load of the bridge or other infrastructure. Additionally, they can be utilized for drainage systems, carrying water or sewage away from the site. Overall, steel pipes play an essential role in enhancing the strength, durability, and functionality of bridges and infrastructure projects.

What are the considerations for selecting the right alloy for steel pipes?

When selecting the right alloy for steel pipes, there are several key considerations to keep in mind. Firstly, the intended application and environment must be taken into account. Factors such as temperature, pressure, and exposure to corrosive substances will dictate the required strength and resistance properties of the alloy. Additionally, the desired durability, flexibility, and cost-effectiveness must also be considered. Other factors like ease of fabrication, availability, and compatibility with other materials may also influence the alloy selection process. Ultimately, the choice of alloy should be based on a thorough assessment of these considerations to ensure optimal performance and longevity of the steel pipes in their intended application.

Wholesale Steel Pipes from supplier in Honduras

Our team of experts is dedicated to assisting you with all your Steel Pipes needs, from product selection to technical specifications. We understand the importance of finding the right Steel Pipes products for your specific requirements, and we are committed to delivering high-quality solutions that meet your expectations.

In addition to our extensive product range, we also offer competitive pricing and efficient delivery options to ensure that your projects stay on schedule and within budget. Whether you need Steel Pipes for construction, infrastructure, or any other industry, we have the expertise and resources to fulfill your requirements.

Furthermore, our technical support team is available to provide guidance and assistance throughout the entire procurement process. We can help you navigate through different grades, dimensions, and specifications to find the most suitable Steel Pipes products for your applications. Our goal is to ensure that you receive the right products and achieve optimal results for your projects.

At our company, customer satisfaction is our top priority. We strive to build long-term partnerships with our clients by providing exceptional services and reliable Steel Pipes products. With our strong backing from CNBM, you can trust us to deliver the highest quality products and services in the industry.

Contact us today to discuss your Steel Pipes requirements and let us provide you with the best solutions for your projects in Honduras.

In addition to our extensive product range, we also offer competitive pricing and efficient delivery options to ensure that your projects stay on schedule and within budget. Whether you need Steel Pipes for construction, infrastructure, or any other industry, we have the expertise and resources to fulfill your requirements.

Furthermore, our technical support team is available to provide guidance and assistance throughout the entire procurement process. We can help you navigate through different grades, dimensions, and specifications to find the most suitable Steel Pipes products for your applications. Our goal is to ensure that you receive the right products and achieve optimal results for your projects.

At our company, customer satisfaction is our top priority. We strive to build long-term partnerships with our clients by providing exceptional services and reliable Steel Pipes products. With our strong backing from CNBM, you can trust us to deliver the highest quality products and services in the industry.

Contact us today to discuss your Steel Pipes requirements and let us provide you with the best solutions for your projects in Honduras.