All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

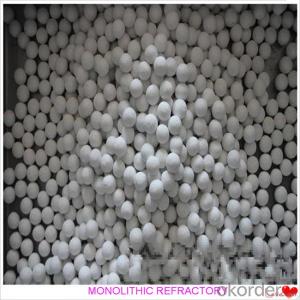

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

What are the typical applications of monolithic refractories?

Monolithic refractories are commonly used in a variety of applications where high temperatures, abrasion, corrosion, and thermal shock resistance are required. Some typical applications include lining of furnaces, kilns, ladles, tundishes, and other high-temperature equipment in industries such as steel, cement, glass, ceramics, and petrochemicals. Additionally, monolithic refractories are used for repairing and maintaining these equipment, as well as in the construction of chimneys, incinerators, and other thermal processing units.

What is the recommended heating rate for monolithic refractories during initial drying?

The recommended heating rate for monolithic refractories during initial drying is typically around 50-100 degrees Celsius per hour.

Are monolithic refractories suitable for use in rotary furnaces?

Yes, monolithic refractories are suitable for use in rotary furnaces. Monolithic refractories are known for their excellent thermal shock resistance, which is crucial for the extreme temperature changes experienced in rotary furnaces. Additionally, their ability to easily conform to complex shapes makes them a practical choice for lining the rotating walls of the furnace.

How do monolithic refractories handle thermal insulation and energy efficiency?

Monolithic refractories are efficient in thermal insulation and energy conservation due to their low thermal conductivity and high thermal resistance. They have the ability to withstand high temperatures and resist heat transfer, thereby minimizing heat loss and maximizing energy efficiency. Additionally, their homogeneous structure and absence of joints or seams further enhance their insulation properties, making them an ideal choice for applications that require thermal insulation and energy conservation.

Wholesale Monolithic Refractories from supplier in Honduras

Whether you require Monolithic Refractories for steel production, cement manufacturing, or other industrial applications, we have the products and knowledge to meet your specific needs. Our team of experts can assist you in selecting the right refractory materials based on your project requirements, ensuring optimum performance and durability.

In addition to our wide range of products, we also provide comprehensive technical support throughout the entire procurement process. From initial consultation to product delivery and installation, our dedicated team will guide you every step of the way, ensuring a seamless and hassle-free experience.

As a subsidiary of CNBM, we have access to a global network of resources, enabling us to offer competitive prices and timely delivery. We understand the importance of efficiency and cost-effectiveness in today's competitive market, and we strive to provide the best value for your investment.

At our core, we prioritize customer satisfaction and long-term partnerships. We believe in building strong relationships with our clients, and we are committed to providing exceptional customer service. Our team is always available to address any inquiries or concerns you may have, and we are dedicated to finding solutions that meet your specific needs.

Whether you are a small-scale operation or a large industrial facility, we have the expertise and resources to meet your Monolithic Refractories requirements in Honduras. Contact us today to discuss your project and let us be your trusted partner in the procurement of high-quality refractory materials.

In addition to our wide range of products, we also provide comprehensive technical support throughout the entire procurement process. From initial consultation to product delivery and installation, our dedicated team will guide you every step of the way, ensuring a seamless and hassle-free experience.

As a subsidiary of CNBM, we have access to a global network of resources, enabling us to offer competitive prices and timely delivery. We understand the importance of efficiency and cost-effectiveness in today's competitive market, and we strive to provide the best value for your investment.

At our core, we prioritize customer satisfaction and long-term partnerships. We believe in building strong relationships with our clients, and we are committed to providing exceptional customer service. Our team is always available to address any inquiries or concerns you may have, and we are dedicated to finding solutions that meet your specific needs.

Whether you are a small-scale operation or a large industrial facility, we have the expertise and resources to meet your Monolithic Refractories requirements in Honduras. Contact us today to discuss your project and let us be your trusted partner in the procurement of high-quality refractory materials.

Hot Search

- Monolithic Refractories in Pakistan

- Ceramic Fiber Products in Lebanon

- Refractory Bricks in Iran

- Raw Materials For Refractory in Luxembourg

- Refractory Bricks in Montenegro

- Raw Materials For Refractory in Tuvalu

- Raw Materials For Refractory in Sweden

- Refractory Bricks in Spain

- Ceramic Fiber Products in Norway

- Ceramic Fiber Products in Latvia