All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How are silica carbide bricks used in aluminum reduction cells?

Silica carbide bricks are used in aluminum reduction cells as lining materials for the inner walls of the cell. They are resistant to high temperatures and chemical corrosion, making them ideal for the harsh environment of the reduction process. The bricks provide insulation, prevent metal penetration, and maintain structural integrity, ensuring efficient and safe aluminum production.

What are the applications of refractory materials?

Refractory materials are extensively used in various industries such as steel, cement, glass, and petrochemicals. They are used in applications where high temperatures, corrosion, and abrasion resistance are required. Some common applications include lining of furnaces, boilers, kilns, and incinerators, as well as in the production of metal alloys, ceramics, and glass products.

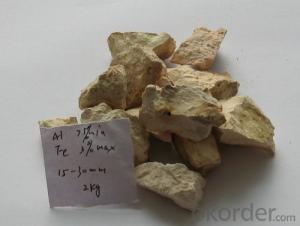

How are raw materials for refractory obtained?

Raw materials for refractory are obtained through various methods such as mining, extraction, and processing. These materials are typically sourced from natural deposits or synthetic sources. Common raw materials for refractory include minerals like bauxite, magnesite, silica, and alumina, which are then transformed into refractory products through a series of manufacturing processes.

How do different types of silica compare in terms of performance in refractory applications?

Different types of silica, such as fused silica, silica flour, and silica sand, have varying performance characteristics in refractory applications. Fused silica, which is made by melting high-purity silica, exhibits excellent thermal stability and resistance to thermal shock, making it suitable for high-temperature applications. Silica flour, which is finely ground silica, provides good flowability and can enhance the workability of refractory mixes. Silica sand, with its larger particle size, offers good strength and can help improve the mechanical properties of refractory materials. Overall, the choice of silica type depends on the specific requirements of the refractory application.

Wholesale Raw Materials For Refractory from supplier in Honduras

Whether you are looking for high-quality raw materials such as magnesia, alumina, silica, or graphite, we have a wide range of options to suit your needs. Our products are sourced from reliable suppliers and undergo strict quality control measures to ensure that they meet the highest industry standards.

In addition to our excellent product range, we also offer competitive pricing to help you optimize your costs without compromising on quality. Our team of experts is dedicated to providing personalized solutions and technical support to assist you in selecting the right raw materials for your specific requirements.

As a subsidiary of CNBM, we have access to a vast network of resources and expertise. This enables us to efficiently handle large orders and ensure timely delivery to our customers in Honduras. Our strong global presence and reputation in the industry further guarantee that you are partnering with a trustworthy and reliable supplier.

We understand the unique challenges and opportunities in the Honduras market and are committed to helping our customers succeed. Our experienced team is well-versed in the local market dynamics and can provide valuable insights and guidance to support your projects. Whether you are involved in the production of refractory bricks, castables, or other refractory products, we have the knowledge and expertise to assist you.

At our company, customer satisfaction is our top priority. We strive to build long-term relationships with our customers by delivering high-quality products, exceptional service, and reliable support. Contact us today to discuss your raw material requirements for refractory products in Honduras, and let us be your trusted partner in achieving success.

In addition to our excellent product range, we also offer competitive pricing to help you optimize your costs without compromising on quality. Our team of experts is dedicated to providing personalized solutions and technical support to assist you in selecting the right raw materials for your specific requirements.

As a subsidiary of CNBM, we have access to a vast network of resources and expertise. This enables us to efficiently handle large orders and ensure timely delivery to our customers in Honduras. Our strong global presence and reputation in the industry further guarantee that you are partnering with a trustworthy and reliable supplier.

We understand the unique challenges and opportunities in the Honduras market and are committed to helping our customers succeed. Our experienced team is well-versed in the local market dynamics and can provide valuable insights and guidance to support your projects. Whether you are involved in the production of refractory bricks, castables, or other refractory products, we have the knowledge and expertise to assist you.

At our company, customer satisfaction is our top priority. We strive to build long-term relationships with our customers by delivering high-quality products, exceptional service, and reliable support. Contact us today to discuss your raw material requirements for refractory products in Honduras, and let us be your trusted partner in achieving success.

Hot Search

- Monolithic Refractories in Kyrgyzstan

- Ceramic Fiber Products in Lesotho

- Refractory Bricks in Paraguay

- Raw Materials For Refractory in Tuvalu

- Ceramic Fiber Products in Mauritius

- Raw Materials For Refractory in Fiji

- Ceramic Fiber Products in Bulgaria

- Refractory Bricks in Iceland

- Raw Materials For Refractory in Togo

- Refractory Bricks in Japan