All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

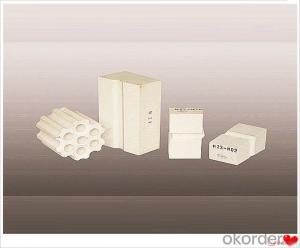

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How do refractory bricks contribute to reducing downtime in industrial processes?

Refractory bricks contribute to reducing downtime in industrial processes by providing high heat resistance and insulation, ensuring the efficient functioning of furnaces, kilns, and other high-temperature equipment. These bricks can withstand extreme temperatures, preventing thermal damage and prolonging the lifespan of the equipment. By minimizing the need for frequent repairs and replacements, refractory bricks help to maintain uninterrupted production, thereby reducing downtime in industrial processes.

How do refractory bricks resist thermal radiation?

Refractory bricks resist thermal radiation due to their ability to withstand high temperatures and transfer heat slowly. The bricks are made from materials with low thermal conductivity and high melting points, which prevent the transfer of heat through the material. This allows them to effectively insulate against thermal radiation and maintain their structural integrity under extreme heat conditions.

Can refractory bricks improve the lifespan of industrial equipment?

Yes, refractory bricks can improve the lifespan of industrial equipment. Refractory bricks are highly heat-resistant and can withstand extreme temperatures, making them ideal for lining furnaces, kilns, and other high-temperature industrial equipment. By using refractory bricks, the equipment is protected from heat damage and thermal shock, which can significantly extend its lifespan. Additionally, refractory bricks also provide insulation, reducing energy consumption and improving overall efficiency.

What are the refractory linings used in furnaces?

Refractory linings used in furnaces are typically made of materials such as fire clay, silica, alumina, and magnesia. These linings are designed to withstand high temperatures and protect the furnace structure from the intense heat generated during the combustion process.

Can refractory bricks be used in pottery kilns?

Yes, refractory bricks can be used in pottery kilns. Refractory bricks are designed to withstand high temperatures and provide insulation, making them suitable for use in pottery kilns where high temperatures are required for firing clay.

Wholesale Refractory Bricks from supplier in Paraguay

Whether you are in need of high-quality Refractory Bricks for industrial applications, construction projects, or any other specific requirements, our team of experts is ready to assist you. We understand the importance of selecting the right Refractory Bricks for your needs, as they play a crucial role in maintaining the integrity and efficiency of various high-temperature processes.

Our sales team is dedicated to providing personalized support and guidance throughout the entire purchasing process. We offer competitive prices and flexible payment options to ensure that you receive the best value for your investment. Our strong relationships with leading manufacturers allow us to source and deliver Refractory Bricks that meet the highest quality standards.

Furthermore, we offer comprehensive technical support to help you make informed decisions. Our team of engineers and technicians can provide guidance on the selection, installation, and maintenance of Refractory Bricks. We understand the unique challenges and requirements of different industries and can tailor our recommendations to suit your specific needs.

At our company, customer satisfaction is our top priority. We strive to exceed your expectations by delivering reliable products and exceptional service. Whether you have a small or large-scale project, we are committed to providing you with the best solutions for your Refractory Bricks needs in Paraguay.

Contact us today to learn more about our products and services. We look forward to partnering with you and contributing to the success of your projects.

Our sales team is dedicated to providing personalized support and guidance throughout the entire purchasing process. We offer competitive prices and flexible payment options to ensure that you receive the best value for your investment. Our strong relationships with leading manufacturers allow us to source and deliver Refractory Bricks that meet the highest quality standards.

Furthermore, we offer comprehensive technical support to help you make informed decisions. Our team of engineers and technicians can provide guidance on the selection, installation, and maintenance of Refractory Bricks. We understand the unique challenges and requirements of different industries and can tailor our recommendations to suit your specific needs.

At our company, customer satisfaction is our top priority. We strive to exceed your expectations by delivering reliable products and exceptional service. Whether you have a small or large-scale project, we are committed to providing you with the best solutions for your Refractory Bricks needs in Paraguay.

Contact us today to learn more about our products and services. We look forward to partnering with you and contributing to the success of your projects.

Hot Search

- Monolithic Refractories in Afghanistan

- Ceramic Fiber Products in Portugal

- Refractory Bricks in Dominican

- Raw Materials For Refractory in Italy

- Ceramic Fiber Products in Singapore

- Raw Materials For Refractory in Albania

- Ceramic Fiber Products in Egypt

- Monolithic Refractories in Yemen

- Monolithic Refractories in Burundi

- Refractory Bricks in Cuba