All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

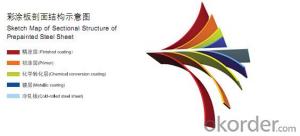

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do steel strips contribute to the production of electrical transformers?

Steel strips contribute to the production of electrical transformers by providing a core material that has high magnetic permeability, allowing it to efficiently conduct and transfer electrical energy. The steel strips are used to create the laminated core of the transformer, which helps reduce energy loss due to eddy currents and increases the overall efficiency and performance of the transformer.

What are the properties that make high-strength low-alloy (HSLA) steel strips suitable for specific applications?

High-strength low-alloy (HSLA) steel strips possess several properties that make them suitable for specific applications. Firstly, they have significantly higher strength compared to traditional carbon steel, allowing for reduced thickness and weight while maintaining structural integrity. This makes HSLA steel strips ideal for applications where lightweight yet strong materials are required, such as in automobile manufacturing or aerospace industries. Additionally, HSLA steel strips exhibit excellent corrosion resistance due to the addition of alloying elements like chromium, nickel, and copper. This corrosion resistance makes them suitable for outdoor or marine applications where exposure to moisture or harsh environments is expected. Lastly, HSLA steel strips offer good weldability and formability, enabling them to be easily processed and shaped into various components, providing versatility in manufacturing applications. Overall, the combination of high strength, corrosion resistance, and formability makes HSLA steel strips a preferred choice for specific industries and demanding applications.

What are the considerations for using steel strips in the production of efficient and eco-friendly public transportation systems?

There are several considerations for using steel strips in the production of efficient and eco-friendly public transportation systems. Firstly, steel is a highly durable and strong material, making it suitable for withstanding heavy loads and providing a long service life for transportation infrastructure. This ensures that the systems can operate efficiently and reliably for a prolonged period.

Secondly, steel strips can be manufactured using recycled materials, reducing the environmental impact associated with mining and extracting raw materials. The use of recycled steel not only conserves natural resources but also reduces energy consumption and greenhouse gas emissions during the manufacturing process.

Additionally, steel strips offer excellent resistance to corrosion and rust, which is crucial for public transportation systems that are exposed to various weather conditions and moisture. The longevity of steel strips reduces maintenance needs and associated costs, making it a cost-effective choice for sustainable transportation infrastructure.

Furthermore, steel strips can be easily fabricated and customized to fit specific design requirements, allowing for more efficient construction and installation processes. This flexibility contributes to reduced construction time and disruption to existing transportation networks, ultimately leading to a more efficient and eco-friendly public transportation system.

Overall, the considerations for using steel strips in the production of efficient and eco-friendly public transportation systems include its durability, recyclability, resistance to corrosion, and flexibility in design and construction processes.

Wholesale Steel Strips from supplier in Libya

Our team of experts is dedicated to assisting you throughout the entire procurement process. From understanding your specific needs to providing you with customized solutions, we are here to ensure that you receive the highest quality Steel Strips. Our sales team is available to answer any queries you may have and provide you with detailed quotations.

Additionally, we offer technical support services to assist you in choosing the right Steel Strips for your projects. Our technical experts can guide you through the various specifications and help you make informed decisions. With their expertise, you can be confident that you are choosing the best Steel Strips for your applications.

As a subsidiary of CNBM, we have access to a vast network of suppliers, ensuring that we can meet your Steel Strips requirements efficiently and effectively. Our strong relationships with manufacturers enable us to offer competitive prices without compromising on quality.

Furthermore, our years of experience in the Libyan market have given us valuable insights into the local industry. We understand the unique challenges and requirements of the Libyan market, allowing us to provide you with tailored solutions. Whether you are working on construction projects, industrial applications, or any other steel-related projects, we have the knowledge and expertise to support you.

In summary, our comprehensive range of Steel Strips, sales assistance, quotations, and technical support services, combined with our experience in the Libyan market, make us the ideal partner for all your Steel Strips procurement needs. Contact us today to discuss your requirements and let us assist you in achieving the success of your projects.

Additionally, we offer technical support services to assist you in choosing the right Steel Strips for your projects. Our technical experts can guide you through the various specifications and help you make informed decisions. With their expertise, you can be confident that you are choosing the best Steel Strips for your applications.

As a subsidiary of CNBM, we have access to a vast network of suppliers, ensuring that we can meet your Steel Strips requirements efficiently and effectively. Our strong relationships with manufacturers enable us to offer competitive prices without compromising on quality.

Furthermore, our years of experience in the Libyan market have given us valuable insights into the local industry. We understand the unique challenges and requirements of the Libyan market, allowing us to provide you with tailored solutions. Whether you are working on construction projects, industrial applications, or any other steel-related projects, we have the knowledge and expertise to support you.

In summary, our comprehensive range of Steel Strips, sales assistance, quotations, and technical support services, combined with our experience in the Libyan market, make us the ideal partner for all your Steel Strips procurement needs. Contact us today to discuss your requirements and let us assist you in achieving the success of your projects.