All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

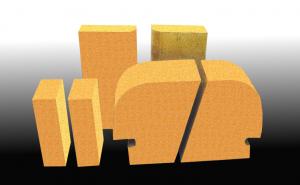

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

What is the difference between monolithic and shaped refractories?

Monolithic refractories are made from a single material and are usually in a paste or powder form that can be easily shaped and installed. They are typically used for lining large and complex structures, such as kilns or furnaces.

On the other hand, shaped refractories are pre-formed into specific shapes, such as bricks, tiles, or blocks, before being installed. They are often used for lining smaller and simpler structures, like chimneys or fireplaces.

In summary, the main difference between monolithic and shaped refractories lies in their form and application, with monolithic being more versatile for complex structures and shaped being more suitable for simpler ones.

What are the refractory materials used in the petrochemical industry?

Refractory materials commonly used in the petrochemical industry include firebricks, castables, and ceramic fibers. These materials possess high resistance to heat, chemicals, and mechanical stress, making them suitable for lining furnaces, reactors, and other equipment used in the production and processing of petrochemicals.

How do refractory materials work?

Refractory materials work by withstanding high temperatures and harsh environments without undergoing significant physical or chemical changes. They have high melting points and low thermal conductivity, allowing them to retain their structural integrity and insulating properties in extreme conditions. These materials often contain oxides, carbides, or nitrides of metals like aluminum, silicon, or magnesium, which form a protective layer when exposed to heat, preventing further damage.

Wholesale Refractory Materials from supplier in Libya

Our team of experts is highly knowledgeable and experienced in the field of Refractory Materials. We can provide you with accurate and detailed quotations for the products you need, ensuring that you receive the best value for your investment. Our technical support services are designed to assist you throughout the entire process, from product selection to installation and maintenance.

As a subsidiary of CNBM, we have access to a wide network of suppliers and manufacturers, allowing us to source high-quality Refractory Materials at competitive prices. We can handle all aspects of procurement, including logistics and delivery, ensuring a seamless experience for our customers.

We understand the unique challenges and requirements of the Libyan market and can tailor our services to meet your specific needs. Our team is well-versed in the local regulations and industry standards, ensuring compliance and efficiency in all our operations.

By choosing us as your supplier of Refractory Materials in Libya, you can benefit from our extensive experience and expertise. We have successfully completed numerous projects in the region and have a proven track record of delivering high-quality products and services.

Contact us today to discuss your Refractory Materials needs in Libya, and let us provide you with the best solutions for your projects.

As a subsidiary of CNBM, we have access to a wide network of suppliers and manufacturers, allowing us to source high-quality Refractory Materials at competitive prices. We can handle all aspects of procurement, including logistics and delivery, ensuring a seamless experience for our customers.

We understand the unique challenges and requirements of the Libyan market and can tailor our services to meet your specific needs. Our team is well-versed in the local regulations and industry standards, ensuring compliance and efficiency in all our operations.

By choosing us as your supplier of Refractory Materials in Libya, you can benefit from our extensive experience and expertise. We have successfully completed numerous projects in the region and have a proven track record of delivering high-quality products and services.

Contact us today to discuss your Refractory Materials needs in Libya, and let us provide you with the best solutions for your projects.

Hot Search

- Monolithic Refractories in South Korea

- Ceramic Fiber Products in Pakistan

- Refractory Bricks in Liberia

- Raw Materials For Refractory in British

- Refractory Bricks in Chile

- Raw Materials For Refractory in Brunei

- Ceramic Fiber Products in Zambia

- Ceramic Fiber Products in Armenia

- Ceramic Fiber Products in United Arab Emirates

- Ceramic Fiber Products in Guinea Bissau