CMAX 96/128 Ceramic Fiber Blanket for Fire Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fiber Blanket Spun Process Supplier

Ceramic Fibre Blanket is ideal thermal insulation material, fire-proof material and sound-absorbing material. Ceramic fiber blanket has even texture and smooth surface. CNBM ceramic fiber blanket is made of high quality alumina-silicate ceramic fiber by using double side needling methods which improve the tensile strength and the flatness of the ceramic fiber blanket. Our ceramic fiber blanket providing effective solutions to a wide range of thermal management problems. Utilizing our proprietary high output blowing and spinning techniques, these products supply superior insulating performance, flexibility and resilience.

Product Applications:

Ceramic Fiber Blanket are ideal for use in the below applications

Heat treating furnace or intermittent (shuttle) kiln hot face lining

Electrical Insulator

High Temperature Acoustic

Fire protection

Incineration equipment and stack linings

Product Advantages:

Professional manufacturer of ceramic fiber products with more than 12 year experience.

We are one of the manufacturers who can produce ultra-thin blanket.

Our factory equipped with 23 production lines to ensure a timely delivery

Main Product Features:

High tensile strength and low shrinkage

Good resiliency with low heat storage

Low thermal conductivity

Good sound aboption

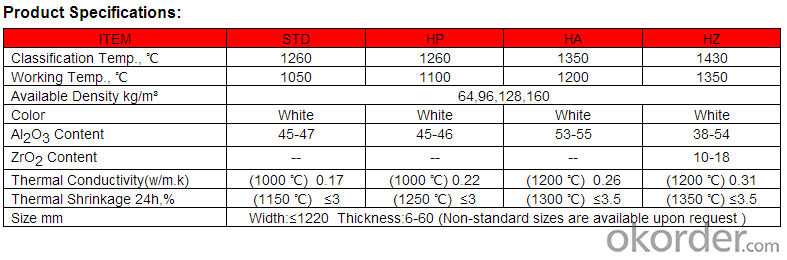

Product Specifications:

FAQ:

Q1: Are you a manufacture or trader?

A: Factory+trade (mainly for manufacturing, also do some business of related products).

Q2: What's the MOQ of trial order?

A: No limit,We can offer the best suggestions and solutions according to your requirements.

Q3: After an order is confirmed,when to deliver?

A: According to your order quantity, normally, 15-25 days after deposit received.

Q4: Is your company accept customization?

A: We have our own factories and excellent technical team, and we accept OEM service.

Q5: What certificates do you have?

A: ISO9001, BV and Test Report, also we can do other necessary certification according to your requirements.

Q6: Can you offer samples?

A: Of course,samples are total free! Freight should be paid by buyers.

Product Picture

- Q:I am 13 years old and am 5'4quot;(female)I weigh 115 pounds.( I know that that is a little overweight.) I eat very healthy, and exercise a lotI do not look overweight, other than a stomach poochMy mother had/has a stomach pooch since she was around my ageI do a lot of sit ups and crunches, but no matter what exercise I do, I can't get rid of my poochI will list all of the exercises I have tried:1running2.jogging3.walking4.jumping jacks5.jump rope6.swimming7.sit ups8crunches.and many moreWhat else besides eating right will get rid of my belly pooch? What are easy exercises? harder exercises? other things?thanks in advanceserious answers please.

- Will require an oven proof dish such as corning ware casserole etcbut I do mine in a slow cooker.

- Q:Can you tell me where to find info on 100% cotton flannel fabric? Like how it's made and what's so good about it?

- Most fruits and vegetables are good at lowering high cholesterolI've heard good things about cranberries especially, just make him step away from fast food, and refined carbohydratesNuts and seeds, avocadoes, olive oil, and dark chocolate, are full of healthy fats that raise good cholesterol, and lower bad cholesterolFoods with soluble fiber, such as oats, are also goodDon't think that canola and soybean oil or corn oil are healthy, usually they go rancid before they hit the bottle, and all their goodness is goneWhat's worse, is that they go through bleaching and deodorizing, all of which use chemicals that are harmful to the bodyAlso, make him exercise.

- Q:I eat pretty healthy, mostly a diet high in fiber? Does that cause smelly farts? I know things like meat do, but I don't eat a lot of thatAnd I drink lots of water.

- How about giving yourself a enema DAILY! that might help.

- Q:this place Pleasant VAlley Modular has HUGE BATHROOMS AND GORGEOUS kitchens go ahead even check out their website.but they cost more than a stick build that has about 1000 more sq feetTHe one builder was going to do a stick build at 130 a sq ft and we're finding out the modular will be 158 per sq ft does that make sense? we tried asking why the modular builder said its because it includes more (all appliances including wash dryer) the nicer bath kitchenis he ripping up off or what? please go on the site look under kitchens baths so you know what these things are.theyre not just regular modulars, they come w/ full superior wall system basments and walk up attics but still my parents are very controlling even though im married have 2 kids, my mom gets upset, hangs up on me because she thinks were getting ripped off were not doing what she woul do! we're not getting along but these houses r really nice!!HELP need people w/ experience in building or buying to answer

- you have to get all the teleporters working

- Q:It feels that way.

- Most stores will have it with the Glad Wrap, Tin Foiletc

- Q:Can I buy the yarn already puffed up the way they show on ytube or do I need to unravel it myself.What is this yarn called, is it wool and does it have to be a certain type?

- Make Over 200 Juicy, Mouth-Watering Paleo Recipes You've NEVER Seen or Tasted Before?

- Q:I like the taste of high fiber cereal, but it really clogs me upI have tried drinking extra water and it did not helpDoes it do other people this way?

- Aluminum is quite often superior to carbon steel for corrosion resistanceAlso note that aluminum has been traditionally more suited for aircraft bodies and is only now being replaced by composite materials for weight and fuel efficiencyAluminum is quite often used for engine blocks with steel sleeves lining the piston cylindersThe littoral combat ships and many corvettes used in navies are often aluminum bodiesAluminum is often used as a substitute for copper in certain conductor applications because of its costThere are many others where the aluminum industry is finding applications to replace steelAnd when considering their success, you may want keep an eye on them for possible investment.

- Q:I just painted my nails and i accidently got it on my throw/blanket on my bed i really need to get it out as its my favorite one and its not reversible its 100% Polyester How can i get this out as quick as possible???

- Vacuum Seal the food (try the Foodsaver machine)

- Q:I bought several squares that were already crochetedI would like to sew them together to make a queen size blanket for my brotherI would like to know my options and which one you think is the easiestThanks

- This might seem crazy as anything but isolate a single or a teeny tiny number of iron atoms and place it within a sphere constructed of electromagnets, create as close to a vacuum as possible and reduce the temperature to as close to absolute zero as you can, then turn on those big ol' magnets and see what happensI think the atom will just float in the middle.

- Q:My husband and I are trying to lose weight and I was just looking around for some healthy recipes and any tips anyone might have to help lose weight and keep it offand also does anyone keep a food diary?? Just writing down eveything that you eat everyday I think I heard about this on Tyra?? Has anyone tried using one or ever heard of it????Thanks.

- This is the best cheesecake recipe I've ever found, and I spent about 5 years experimenting! Feel free to add mini chocolate chips, and drizzle with caramel sauce! It's not totally necessary, but I find I get better results, when I wrap the outside of the pan with 2 layers of heavy duty foil, and put the cheesecake in a roasting pan with water around it (hot water bath)It makes the cheesecake cook more evenly without any crackingCheesecake INGREDIENTS: 1 1/2 cups graham cracker crumbs 1/2 cup white sugar 1/4 cup butter, melted 5 (8 ounce) packages cream cheese, softened 5 eggs 2 egg yolks 1 3/4 cups white sugar 1/8 cup all-purpose flour 1/4 cup heavy whipping cream DIRECTIONS: 1Preheat oven to 400 degrees F (200 degrees C)2Mix the graham cracker crumbs, 1/2 cup of the white sugar, and the melted butter togetherPress mixture into the bottom of one 9 or 10 inch springform pan3In a large bowl, combine cream cheese, eggs and egg yolks; mix until smoothAdd the remaining 1 3/4 cups white sugar, the flour and the heavy creamBlend until smoothPour batter into prepared pan4Bake at 400 degrees F (200 degrees C) for 10 minutes, then turn oven temperature down to 300 degrees F (100 degrees C) and continue baking for 1 hour, or until filling is setLet cheesecake cool, then refrigerate.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX 96/128 Ceramic Fiber Blanket for Fire Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords