Ceramic Fiber Blanket for Furnace and Boiler Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fiber Blanket Spun Process Supplier

Ceramic Fibre Blanket is ideal thermal insulation material, fire-proof material and sound-absorbing material. Ceramic fiber blanket has even texture and smooth surface. CNBM ceramic fiber blanket is made of high quality alumina-silicate ceramic fiber by using double side needling methods which improve the tensile strength and the flatness of the ceramic fiber blanket. Our ceramic fiber blanket providing effective solutions to a wide range of thermal management problems. Utilizing our proprietary high output blowing and spinning techniques, these products supply superior insulating performance, flexibility and resilience.

Product Applications:

Ceramic Fiber Blanket are ideal for use in the below applications

Heat treating furnace or intermittent (shuttle) kiln hot face lining

Electrical Insulator

High Temperature Acoustic

Fire protection

Incineration equipment and stack linings

Product Advantages:

Professional manufacturer of ceramic fiber products with more than 12 year experience.

We are one of the manufacturers who can produce ultra-thin blanket.

Our factory equipped with 23 production lines to ensure a timely delivery

Main Product Features:

High tensile strength and low shrinkage

Good resiliency with low heat storage

Low thermal conductivity

Good sound aboption

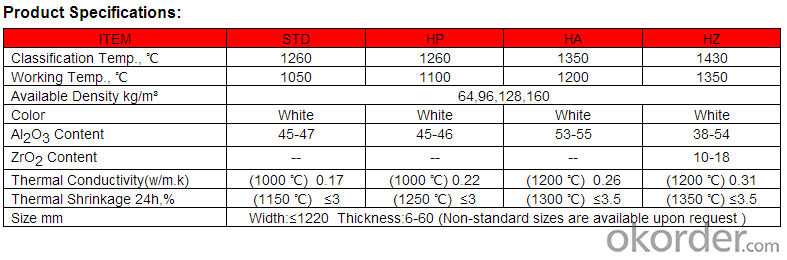

Product Specifications:

FAQ:

Q1: Are you a manufacture or trader?

A: Factory+trade (mainly for manufacturing, also do some business of related products).

Q2: What's the MOQ of trial order?

A: No limit,We can offer the best suggestions and solutions according to your requirements.

Q3: After an order is confirmed,when to deliver?

A: According to your order quantity, normally, 15-25 days after deposit received.

Q4: Is your company accept customization?

A: We have our own factories and excellent technical team, and we accept OEM service.

Q5: What certificates do you have?

A: ISO9001, BV and Test Report, also we can do other necessary certification according to your requirements.

Q6: Can you offer samples?

A: Of course,samples are total free! Freight should be paid by buyers.

Product Picture

- Q:Sometimes i get late night craving (like many people do)but i don't want to eat anything unhealthy, and fiber one cereal are very healthy and high on fiber, but i was wondering if it will be unhealthy? like perhaps weight gain?

- If you are experiencing hunger at night, choosing a nutritious snack can be beneficial in helping you meet your daily nutritional needsI'm a big fan of the Kellogg's FiberPlus(R) cereals which are also high in fiber and contain the antioxidants C and E.

- Q:We bought a used well pump from a reputable dealerWhile the line was out we notices several abrasions along the 165' of electrical lineWe think we repaired them all, including enclosing them in that shrink wrap stuffThe pump worked fine out of water, put when they lowered it into the well it wouldn't workWe pulled it up again, same thingCould there be electrical problem that we can't see, that comes open or something?If so, how do we find the problemTo replace the entire wire is another $165.We did buy a new bladder tank, new pressure control switch, and new pressure gauge.

- Water is reaching electric source somewhere in pumpWhen submerged the water is a load and stealing voltageIf wire insulation is damaged you could try liquid tape, I'm not sure shrink tube is water tightbut its either a seal on the pump, motor winding shorted to case of pump, or the wire insulation is damagedGet multimeter, test for continuity (Ohms) from each wire terminal to pump housingIf you have continuity, pump motor winding is badYou could also test wire with tub of waterturn power off, touch tester lead to wire end put other lead in water pull wire through tub if you get continuity insulation is badIf it is the wire you can buy underground splice kits, they are kind of pricy but may be lessA solid wire is better in the long run though.

- Q:I know I need fiber and water, but I literally have to force water down my throatWhat things have the highest fiber content?I'm a teen so I'm afraid of pills and powders

- Tips to Prevent Constipation Problems and to Relieve Constipation Naturally: Eat high fiber foods such as whole grain breads, bran cereal, raisins, fresh fruit and vegetables Drink plenty of liquids such as water, fruit juices, hot tea or lemon water to stimulate the bowels Ginger tea is an effective natural constipation remedy Regular exercise can help to both prevent and relieve constipation Avoid regular use of laxatives or enemas Avoid alcohol, caffeine, processed and junk food Stool softeners taken daily may help prevent constipation problems Increase your intake of magnesium with supplements or foods such as nuts, seeds or green leafy vegetables For more information, go to:

- Q:what is the best food to give to my diabetic mother? and still control her blood sugar to the best?

- How's about trail mix? Mixed nuts of all types, dried fruits, granola bits, and not covered in oils or sugars.

- Q:Is it dangerous to add foam board insulation by knob and tube wiring? How far away would it have to be not to pose a hazard? Or is it possible(and safe) to add some sort of flooring over the wiring and then add insulation? Any info would be great!

- they have a silver polishing clothe u can buy at the jewery store that is really good and they might have some polish there too but u dont need polishing cream for the cloth.i bet u can go to walmart in the jewelry department and get some polish.just call them first so u dont go out there for nothing!!

- Q:My niece has an American Girl doll that she loves, and want to make more outfits/items for herI babysit her alot, and I think it would be great to work on something with herI don't have a working sewing machine now, so I'd like to make little food or accessories(or basic, easy to make furniture)I was going to use modeling clay to make food or somethingAnyone know a website or have ideas what to make? Any way to make furniture or other accessories without lots of machinery? I can sew by hand, and we can bake(clay), paint, glue, cut, etc.So any ideas? Thanks!

- The CHI iron is the wonderfulit rather is around $one hundred fifty, besides the shown fact that it rather is rather properly worth itI easily have curly hair too and it gets it board immediately and that i take advantage of it enormously much daily and my hair is in super condition.

- Q:Ok so I have a shoot coming up this September and I need to lose around 25 pounds!! Is going on a high protein diet, cutting out refined carbs and fruits, doing 2.5/3 hours treadmill (running/brisk walking/uphill walking and 1 hour pilates a day will help me reach my goal till 15th SeptemberAll i'm planning to eat isChicken, tuna, bell peppers, cucumber, lettuce egg whites, drink lots of water, green tea and hot lemon waterThanks in advance

- my hair is the equal approach whilst i strighten it, placed a few mousse in your hair and make certain you get the roots of ur hair, then blow dry it, it continuously appears higher, desire i helped

- Q:This question was raised by MIKU HAUONE I felt the answer by LJC was the best answerIn my situation I have discovered there is no insulation in the wall, just around the heat registers and in the atticThe house was built in the 1950s, we thought it was insulatedI don’t think this happened last winterTwo things different, a humidifier that works (mounted on the furnace), we painted the exteriorI don’t believe there is a vapor barrier etherThe roof was new 3 years ago and no signs of a leak, vented at the eves, ridge and has three roof ventsIn the basement all the wall stud spaces have insulation stuffed up into them resting on the sillThe one wall I washed with soap and water, removing the mold and drying itIt has remained dryAnother factor is, we live in southwest MI and we’ve had a bad rain storm and several bad snow stormsThe house is 35’ long and 24’ wide the long side faces north on the front and south on the backSo, any other ideas?

- Its too keep the heat in the food and protects it when cooking itLike garlic bread that's in foilIt cooks nice and evenly and soft, as soon as you take the foil off it gets crusty and can burn.

- Q:which is best for breakfast if you want to lose weight, high-fiber cereal or high-fiber fruits?

- High Fiber fruits are healthier, but may not last you til lunchSee other options at Breakfast Ideas in my blogI am on low carb, low fat, high fibre, high protein and a hour brisk walk 5 times a week, and I have lost 31lbs/14kg and gained better healthI am now maintaining my 108lbs/49kg for more than a year, with more fruits and complex carbsDetails such as my experience, meals, snacks, recipes, foods to buy, reading labels, walking as an exercise and to shape the body etc etc,

- Q:rummaging through boxes of assorted paint, yarn, fabric, jewelry,accessories,other craft items and wooden dowels, which haven't been sorted and organized after we moved inbf: quot;Are these your fishnets or mine?quot;

- If so, I'm just glad hell has fishnets(If it exists, I'm surely going there.) D

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Blanket for Furnace and Boiler Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords