Casing and Tubing Pup-joint with API 5CT Standard

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 30000 pc/month

- Option:

- 2-3/8 to 13-3/8

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Structure of Casing and Tubing Pup-joint Description

1.Grade:J55, K55, N80-1, N80-Q, L80, C90, P110

2.We also supply permium thread products by customer's request

3.Size: tubing coupling from 1.9" to 4-1/2",Casing coupling fro4-1/2"to 13-3/8"

4.Type: NU, EU(tubing coupling), STC,LC,BTC(casing coupling).

2. Main Features of Casing and Tubing Pup-joint

1) Advanced test for quality

2) MTC provided

3) Good price and service

3. Casing and Tubing Pup-joint Images

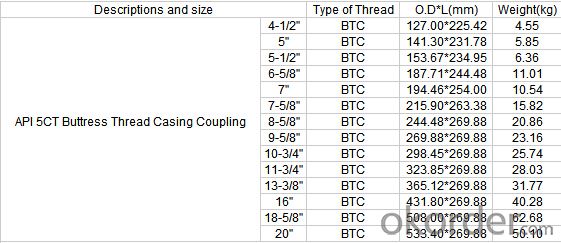

4. Casing and Tubing Pup-joint Specification

5. FAQ of Casing and Tubing Pup-joint

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

One of the leading manufacturers and suppliers specializing in this product in China, supply a wide variety of accessories consists of our one-stop sales. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q:Drawing design, drain cross dry pipe is flexible cast iron pipe, vertical pipe is PVC pipe joint. When it needs to change the diameter, what kind of pipe fittings should be adopted for big head?

- The transverse drain pipe is a flexible cast iron pipe. The vertical pipe is PVC pipe joint. When it needs to change the diameter, it is most suitable to use a special AD type bottom joint.

- Q:which has more quality? natural rubber or synthetic rubber?

- Assuming the Employer is playing Dirty: File for unemployment. This puts the burden of proof on the employer. They might just want to avoid the case or may not feel it is very strong and respond by -no contest- thus allowing you to collect rather then having a series of appeals and hearings. You are rolling the dice a little. How strong is your case and if you wouldn't mind having the particulars of the subject public. If they decide to fight you and you feel your reputation is better served then back out of it and let it die. No harm no foul and you took a good shot at getting Unemployment. -JustThinking

- Q:Right, me and my bf went for a walk and i text my friend and then left my phone on a wall. right next to the wall were gardens, 4 kids were on a trampoline staring at us. when i got home i realised i had forgotten my phone. i ran back to the spot and it was gone, but the children weren't in the garden. we rang it over and over, once someone answered made a screaching sound and hung up the phone. we then went to knock on their door and ask if they had seen it, they said no. now i still dont have my phone, is there anyway i can track it? where i last had it wasnt far away. it has now died, so when we ring it, it goes straight to voicemail. HELP?!?!

- judging from the name of the hand shake i am guessing its a very rough handshake that breaks your bones? lol

- Q:locking shoulder is a part of the upper receiver of an FN FAL Belgian Rifle

- First - think about hiring a handyman to do this. Soldering pipe isn't hard, but learning how to do it while under your house where a leak would be hard to find and repair is not easy. The peace of mind might be worth it. Be sure to ask for an estimate on the price, both for material and for labor, before you agree to anything. If you have to or really want to do it yourself, find a book on DIY plumbing tips. You can probably find one at almost any home improvement stores, like Lowe's, Menards, Home Depot, etc. Then read the parts on making solder joints carefully. Get some pipe and fittings, and practice making joints in the garage, back yard, or someplace well ventilated and easy to work in. Under the house is NOT the place to try this. I'd recommend you try to make at least 20 good joints, and test them by putting them under water pressure to see if they are good. You'll need a propane torch, solder, flux, pipe, fittings, a pipe cleaning brush, and a tubing cutter. The last is a gizmo that cuts copper pipe easily and cleanly. It's MUCH better than using a saw. The brush is a special wire brush that scrubs the corrosion off the inside and outside of the pipe, to help make a better joint. Oh, and get ready for a case of sticker shock when you go to buy copper pipe. The price of copper has skyrocketed lately, so you'll want to be careful to buy only the sizes you need. Read the book about the different kinds and sizes and thicknesses of copper pipe, and look carefully at what you have now, so you know what to get. But you'll still be better off hiring someone to do this, I think.

- Q:I have a daughter who is 8 and wets the bed. She had stopped for a whole year and then started back up. I have tried taking her to the doctor and they say she is normal, I have talked with her and she says she is happy, I have also tried limiting her water intake before bed, but nonthings working. Do anyone know if this is normal? I love my baby, but I want to help her, plus washing the sheet and blankets everyday is getting to be a bit much.

- I really dont know but i know the answer to this Why do firemen have red suspenders??Too keep their pants up. duuuuhhhh

- Q:How do they decide how many alarms to rate a fire?

- Bharat Industrial Corporation 91-129-24462605/2231583 Heera Industries 91-1871-246632 Kaypee International +(91)-(33)-25435268 Kejriwal Pipes Fittings And Valves 91-33-22262312/22262313/22263145

- Q:I have a large collection of LPs, many of which are out of print. I'm not a rare LP collector as such but enjoy the music very much and don't want to lose the music I've amassed. What are some opinions as to the risk(s)/benefits of recording these onto CD-R and giving the bulk of this space hogging vinyl over to the flea market?

- Perhaps those guys are expressing their true feelings, as opposed to putting females down. Anyway, why bother to ask ? You don't even like men to begin with. Or is this just one of those issues where females' lack of power over men is looked upon as something lacking in us men ? And that BS about butch lesbians and studs getting hit on by guys is unbelievable. Or have you taken a good look at any of them lately ?

- Q:Kevin was asked to do a titration analysis of a solution of sulfurous acid to determine its concentration. In order to do the titration, Kevin prepared 100.0 mL of 0.750 mol/L standard solution of sodium hydroxide, then titrated 20.00 mL aliquots of the standard solution with the unknown acid (assume all the reactions go to 100% completion.)A) in four or five steps, describe how kevin prepared standard solution of sodium hydroxide. make sure to include calculationthanks in advance

- Cut your foot off, it will grow back

- Q:why are lightning rods pointed?

- A lightning strike might be 200,000 volts and 50,000 amperes. Unforunately the duration is a fraction of a second. For simple math, let's round it up to 1 second (0.0003 hours). 200 kV x 50 kA x 0.0003 hours 3,000 kWh. This is enough energy to power two average sized mid-west homes for an entire month in the middle of summer. I will let the reader work out the details on how they're going to collect and store this energy for useful purposes..

- Q:Why is the water purifier of the PE pipe and quick connector contact after the start of Water Leakage, can be pulled out after turning and then inserted into the PE pipe does not leak, what is the reason ah, who knows?

- Because there is no plug, the fast joint must be inserted in the end, through the internal sealing ring to play a role.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Casing and Tubing Pup-joint with API 5CT Standard

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 30000 pc/month

- Option:

- 2-3/8 to 13-3/8

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords