Carbon Steel Welding Wires Electrodes Carbon

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

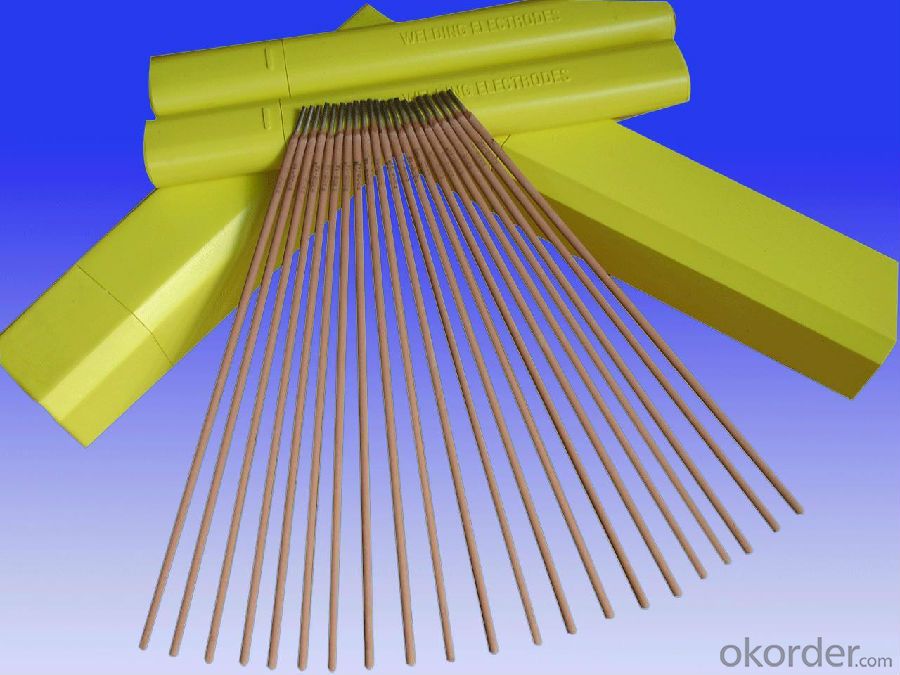

Structure of Carbon Steel Welding Wire Electrodes

1) Specially for Vertical-down welding

2) Perfect welding performance.

3)Operating current: 2.5MM:30-50,32.MM:70-100,4.0MM:90-140, 5.0MM: 150-200

4)Diameter:2.5mm-5.0mm

5)Material:Carbon Steel

6)Length:300-400mm

7)Delivery Time: 15-30 days after receiving L/C or pre-paid

Main Feature of Carbon Steel Welding Wire Electorde

Detail Package:All products will be standard export package, will be wooden boxes or bundled by steel strips, or as per customer's requirement

steel wire is a high cellulose potassium type welding rod for mild steel.

It is suitable for vertical -down welding and lap welding for sheet structures.

Such as smoke pipes, wind pipes ,oil tanks of teansformer, outside cover of vehicles.

FAQ

Why should you choose us?

Chose happens because of quality, then price, we can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents),

Quick goods delivery, our factories locate near the seaport, which is very convenient for transportation.

Datas Information of Carbon Steel Welding Wire Electorde

Chemical Composition of Deposited Metal(%)

| C | Mn | Si | S | p | Ni | Cr | Mo | V |

| ≤0.2 | ≤1.2 | ≤1.0 | ≤0.035 | ≤0.040 | ≤0.3 | ≤0.2 | ≤0.3 | less than 0.08 |

Pictures:

- Q:How does stainless steel wire perform in abrasive environments?

- Stainless steel wire is highly regarded for its exceptional performance in abrasive environments. Due to its unique composition and structure, stainless steel wire exhibits remarkable resistance to wear, corrosion, and impact in such conditions. It is primarily composed of iron, chromium, and other alloying elements that form a protective layer on the surface, known as a passive film. This passive film acts as a shield against the abrasive particles, preventing direct contact with the underlying metal and minimizing the chances of degradation. The chromium content in stainless steel wire plays a crucial role in its performance in abrasive environments. It forms a thin oxide layer on the surface, which enhances the wire's resistance to corrosion and wear. The presence of other alloying elements, such as nickel and molybdenum, further enhances its resistance to pitting, crevice corrosion, and stress corrosion cracking. Stainless steel wire also possesses excellent mechanical properties, including high tensile strength and toughness. These properties enable it to withstand the abrasive forces and impacts encountered in harsh environments. Additionally, stainless steel wire maintains its integrity even at elevated temperatures, making it suitable for applications in extreme conditions. Furthermore, stainless steel wire is highly versatile and can be manufactured in various grades and sizes to cater to specific requirements. This allows for customization based on the specific abrasive environment, ensuring optimal performance and longevity. In summary, stainless steel wire performs exceptionally well in abrasive environments. Its corrosion resistance, mechanical properties, and ability to withstand wear and impact make it an ideal choice for various applications, including industries such as mining, construction, marine, and aerospace.

- Q:What are the different manufacturing standards for stainless steel wire?

- There are several different manufacturing standards for stainless steel wire, which are established to ensure quality and consistency in the production process. Some of the most common standards include: 1. ASTM (American Society for Testing and Materials) standards: ASTM A580 and ASTM A313 are two widely used standards for stainless steel wire. ASTM A580 specifies the requirements for stainless steel wire, including chemical composition, mechanical properties, and dimensional tolerances. ASTM A313 specifically addresses stainless steel spring wire. 2. ISO (International Organization for Standardization) standards: ISO 9001 is a quality management system standard that applies to the manufacturing of stainless steel wire. ISO 9001 ensures that manufacturers follow a set of procedures to consistently deliver products that meet customer requirements. 3. EN (European Norm) standards: EN 10270-3 is a European standard that provides specifications for stainless steel wire for springs. It defines the requirements for chemical composition, mechanical properties, and surface quality. 4. JIS (Japanese Industrial Standards) standards: JIS G4314 is a Japanese standard that specifies stainless steel wire for springs. It covers the chemical composition, mechanical properties, and surface quality requirements. These standards help manufacturers in maintaining product consistency, ensuring the quality of stainless steel wire, and facilitating international trade by providing a common set of specifications. Compliance with these standards is essential to ensure that stainless steel wire meets the required performance criteria and can be used in a wide range of applications.

- Q:What are the different types of stainless steel wire rope grips available?

- There exists a variety of stainless steel wire rope grips, each possessing its own distinct design and functionality. Some commonly encountered types include: 1. U-Bolt Wire Rope Grips: These grips comprise of a U-shaped bolt threaded on both ends and a saddle that fits over the wire rope. They are frequently employed in light-duty applications, providing a secure grip. 2. Fist Grip Wire Rope Grips: Otherwise known as Bulldog grips, these grips possess a compact design and are easily installed. They consist of a threaded body and a series of jaws that firmly grip the wire rope. Fist grip wire rope grips find widespread use in various industries. 3. Wedge Socket Wire Rope Grips: Designed for heavy-duty applications, these grips establish a robust and secure connection between the wire rope and the fitting. They consist of a wedge-shaped socket inserted into the wire rope, complemented by a retaining clip to ensure its stability. 4. Swageless Wire Rope Grips: These grips eliminate the need for swaging or crimping tools during installation, making them convenient and user-friendly. They consist of a threaded body equipped with a series of jaws that grip the wire rope. Swageless wire rope grips are often employed in marine and architectural sectors. 5. Stainless Steel Wire Rope Clamps: Constructed from stainless steel, these grips are employed to form a loop or eye in a wire rope. They comprise of a saddle, a U-shaped bolt, and a nut. Stainless steel wire rope clamps are ideal for creating temporary or permanent connections. It is crucial to select the appropriate stainless steel wire rope grip based on specific application requirements, load capacity, and environmental conditions. Consulting a knowledgeable supplier or engineer can assist in determining the most suitable grip for a particular project.

- Q:Does a product made of some stainless steel have the same tensile strength due to its different shapes?

- 2 mm 304 stainless steel wire, different in standard tensile strength:1, Japan Standard: SUS304 tensile strength is greater than 520N/mm2;2, American Standard ASTM A240:304 tensile strength is greater than 515N/mm2;3, national standard GB/T1220: tensile strength of greater than or equal to 520-515N/mm2.

- Q:What are the different wire coatings available for stainless steel wire?

- There are several different wire coatings available for stainless steel wire, each offering unique properties and benefits. One common coating is PVC (polyvinyl chloride), which provides excellent resistance to abrasion and chemicals, making it suitable for applications where the wire may be exposed to harsh environments. Another popular option is nylon coating, which offers increased flexibility and durability. Nylon-coated stainless steel wire is often used in applications that require high tensile strength and resistance to moisture. Additionally, there are specialty coatings such as Teflon or PTFE (polytetrafluoroethylene), which provide exceptional temperature resistance and low friction properties, making them ideal for high-temperature or high-friction applications. It is important to choose a wire coating that aligns with the specific requirements of the intended use, considering factors such as environmental conditions, mechanical stress, and chemical exposure.

- Q:Can stainless steel wire be used for heating elements?

- Yes, stainless steel wire can be used for heating elements. Stainless steel has excellent resistance to high temperatures, making it suitable for heating applications. Additionally, it has good corrosion resistance and electrical conductivity, which are important characteristics for efficient heating.

- Q:What are the different finishes available for stainless steel wire?

- There exists a variety of finishes for stainless steel wire, each possessing distinct properties and appearances. 1. The bright finish, which is the most prevalent and elementary finish for stainless steel wire, is achieved through the process of polishing. This results in a surface that is shiny and reflective. The bright finish is predominantly utilized in decorative applications where aesthetics hold significance. 2. The matte finish, also referred to as a satin finish, is attained by brushing the wire with a fine abrasive material. This creates a smooth surface that is non-reflective. The matte finish is commonly preferred in industrial or architectural applications that necessitate a reduction in glare. 3. The coated finish involves applying various materials onto the stainless steel wire in order to enhance its performance or appearance. For instance, a plastic coating can provide insulation or safeguard against corrosion, while a colored coating can add visual appeal. 4. The passivated finish is accomplished through a chemical process known as passivation, which eliminates impurities from the surface of the stainless steel wire. This enhances its resistance to corrosion. The passivated finish is frequently employed in applications where the wire will be exposed to harsh environments or corrosive substances. 5. The electroplated finish entails depositing a thin layer of metal onto the stainless steel wire through the process of electroplating. This can improve the wire's appearance, increase its corrosion resistance, or enhance its conductivity for electrical applications. 6. The annealed finish is achieved through the heat treatment process of annealing, which softens the stainless steel wire and alleviates internal stresses. This finish is often utilized to enhance the wire's formability or to prepare it for further processing, such as bending or shaping. In conclusion, the selection of a finish for stainless steel wire is contingent upon the specific requirements of the application, such as corrosion resistance, aesthetics, or functionality.

- Q:Can stainless steel wire be used for bird control?

- Yes, stainless steel wire can be used for bird control. Stainless steel wire is highly durable and resistant to corrosion, making it an excellent choice for bird control applications. It can be used to create barriers or nets to prevent birds from entering certain areas or roosting on structures. Additionally, stainless steel wire is strong enough to withstand the weight and pressure of birds without breaking or sagging, ensuring long-lasting effectiveness. Overall, stainless steel wire is a reliable and effective solution for bird control.

- Q:What is the process of hydrogen annealing of stainless steel?

- General heat treatment needs to be done by a few procedures, first of all to the need for heat treatment of stainless steel hydrogen back wire for cleaning, in addition to the surface of the paint, oil residue or clean, but also for the purification treatment, this can make stainless steel wire hydrogen back to get the best effect in the whole process. After cleaning, in order to prevent the deformation of heating, it should be fixed with a professional fixture and put into an effective heating zone for preheating.

- Q:What are the different types of stainless steel wire rope hooks?

- There is a variety of stainless steel wire rope hooks available, each designed for specific applications and requirements. Some of the commonly used types are as follows: 1. Clevis Hook: This hook has a clevis pin that can be easily attached or detached from the wire rope, providing a secure connection. It is commonly utilized in lifting and hoisting operations. 2. Eye Hook: This hook has a closed loop or eye at the end, allowing for easy attachment of the wire rope. It is frequently used when the hook needs to be permanently connected to the rope. 3. S-Hook: The S-hook, named after its shape resembling the letter "S," has a curved end used for attaching the hook to the wire rope. It is commonly employed in lighter-duty applications such as hanging signs or securing objects. 4. Carabiner Hook: Shaped like a carabiner, this hook is typically used for climbing or rigging purposes. It includes a spring-loaded gate that facilitates quick attachment or detachment of the wire rope. 5. Snap Hook: Similar to carabiner hooks, snap hooks have a wider, flat shape with a spring-loaded gate. They are commonly used in industries like marine or construction, where quick attachment and detachment are necessary. 6. Swivel Hook: The swivel hook features a rotating mechanism that allows the hook to rotate freely, preventing twisting or kinking of the wire rope. It is frequently used in lifting operations where the load may rotate or spin. To ensure safe and efficient operations, it is vital to select the appropriate type of stainless steel wire rope hook based on the specific application, load capacity, and environmental conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Steel Welding Wires Electrodes Carbon

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords