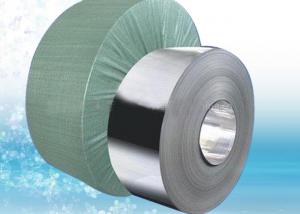

201 2B Stainless Steel Strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

201 2B Stainless Steel Strips

1. Chemical composition of 201 2B Stainless Steel Strips

C | Si | Mn | P | S | Ni | Cr |

max0.15 | max1.00 | 5.50-7.50 | max0.06 | max0.03 | max1.00 | 16.00-18.00 |

2. Mechanical properties of 201 2B Stainless Steel Strips

Yield Strength | Tensile | Elongation | Hardness (HV) | Hardness (HRB) |

245 | 640 | 40 | 253 | 100 |

3. Standard:

AISI, ASTM, GB, EN, DIN, JIS

4. Surface:

2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size:

Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 1000mm or 1219mm or 1240mm for cold rolled, 1500mm for hot rolled.

Length: As customers' request.

6. MOQ: 1 Ton

7. Payment terms:T/T or L/C

8. Packing:

Seaworthy package with wooden or Iron pallets with the paper and the steel strip, or as customers' request.

9. Delivery time:

Usually about 7 days after we confirming the order, or according to your quantity.

If you have any question or demand, pls feel free to contact me.

- Q:202 stainless steel wire can pass 200 hours salt mist test?

- 202 stainless steel wire can not pass 200 hours salt mist test, 202 stainless steel is one of 200 series stainless steel, the national standard model is 1Cr18Mn8Ni5N. 200 series stainless steel is low nickel, high manganese stainless steel, nickel content, manganese content of about 8%, is a nickel type stainless steel. Stainless steel passivation solution can be used to improve the rust resistance and corrosion resistance of stainless steel, improve salt spray test time, should not change the physical appearance of the workpiece, size and conductivity and other physical properties.

- Q:Is stainless steel wire resistant to chemicals?

- Yes, stainless steel wire is generally resistant to chemicals. It has a high level of corrosion resistance, making it suitable for use in various chemical environments.

- Q:What are the different types of stainless steel wire used in automotive exhaust systems?

- There are various types of stainless steel wire commonly used in automotive exhaust systems, each with its own specific properties and advantages. These types include: 1. Type 409: This is the most commonly used stainless steel wire in exhaust systems. It is a ferritic stainless steel that offers good corrosion resistance and heat resistance up to 900°C (1652°F). It is relatively low-cost and provides excellent durability against the harsh conditions found in exhaust systems. 2. Type 304: This is an austenitic stainless steel wire that is often used in high-end or performance exhaust systems. It offers superior corrosion resistance compared to Type 409 and provides better heat resistance up to 1400°C (2552°F). Type 304 stainless steel wire is also known for its aesthetic appeal as it can be polished to a high shine. 3. Type 316: This is another austenitic stainless steel wire that is commonly used in automotive exhaust systems, particularly in areas where the exhaust system is exposed to salt or other corrosive environments. Type 316 stainless steel wire has excellent corrosion resistance properties, even in marine environments, making it ideal for coastal areas or regions with severe weather conditions. 4. Type 321: This stainless steel wire is specifically designed for high-temperature applications in exhaust systems. It contains titanium, which helps to stabilize the wire and prevent it from losing its corrosion resistance properties at temperatures up to 900°C (1652°F). Type 321 stainless steel wire is commonly used in turbocharged or high-performance vehicles where exhaust gas temperatures can be extremely high. 5. Type 441: This is a ferritic stainless steel wire that offers good corrosion resistance and heat resistance up to 950°C (1742°F). It is often used in exhaust systems that require improved thermal stability and durability, such as heavy-duty trucks or vehicles with diesel engines. It is important to choose the right type of stainless steel wire for automotive exhaust systems based on the specific requirements, such as corrosion resistance, heat resistance, and cost-effectiveness. Consulting with a professional or a supplier specializing in automotive exhaust systems can help in selecting the most suitable stainless steel wire for a particular application.

- Q:What are the common uses of stainless steel wire rope?

- Stainless steel wire rope is widely used in various industries due to its exceptional strength, durability, and corrosion resistance properties. Some common uses of stainless steel wire rope include: 1. Lifting and rigging: Stainless steel wire rope is extensively used in lifting and rigging applications, such as cranes, hoists, winches, and material handling equipment. Its high tensile strength and resistance to abrasion make it ideal for safely lifting heavy loads. 2. Structural applications: Stainless steel wire rope is commonly used in architectural and structural applications, such as suspension bridges, cable-stayed bridges, and tension structures. Its ability to withstand high tension forces and harsh environmental conditions makes it a reliable choice for such applications. 3. Marine and offshore industries: Stainless steel wire rope is highly sought after in the marine and offshore industries due to its resistance to corrosion in saltwater environments. It is used for various purposes, including mooring lines, tow lines, fishing nets, and ship rigging. 4. Fencing and balustrading: Stainless steel wire rope is often used in fencing and balustrading systems for its strength and aesthetic appeal. It provides a secure and visually pleasing solution for applications such as perimeter fencing, stair railings, and balcony balustrades. 5. Agriculture and farming: Stainless steel wire rope finds extensive use in the agriculture and farming sector. It is employed for tasks like animal enclosures, vineyard trellising, and crop support systems. Its durability and resistance to weathering make it suitable for outdoor agricultural applications. 6. Automotive industry: Stainless steel wire rope is utilized in the automotive industry for various purposes, including vehicle towing, recovery systems, and suspension components. Its high strength-to-weight ratio and resistance to corrosion make it an excellent choice for these applications. 7. Aerospace industry: Stainless steel wire rope is employed in the aerospace industry for cable support, control mechanisms, and structural components. Its ability to withstand extreme temperatures, high loads, and corrosive environments makes it suitable for critical aerospace applications. Overall, stainless steel wire rope is a versatile material that is used in a wide range of applications across various industries. Its exceptional strength, durability, and corrosion resistance make it a reliable choice for demanding and high-performance applications.

- Q:Can stainless steel wire be used outdoors?

- Yes, stainless steel wire can be used outdoors. Stainless steel is highly resistant to corrosion, making it suitable for various outdoor applications. It can withstand exposure to moisture, sunlight, and extreme temperature conditions without rusting or deteriorating. Stainless steel wire is commonly used in outdoor structures like fences, railings, and garden trellises. It is also used for outdoor electrical wiring, marine applications, and outdoor furniture. The durability and longevity of stainless steel wire make it an excellent choice for outdoor use.

- Q:Can stainless steel wire be used for fishing tackle?

- Fishing tackle can indeed utilize stainless steel wire. This type of wire is renowned for its robustness, longevity, and resistance to rust, making it a popular option for various fishing purposes. One common use is to create leaders, which are segments of line that link the main fishing line to the hook or lure. Stainless steel wire leaders prove particularly beneficial when pursuing aggressive fish species with sharp teeth or rough mouths, as they offer a sturdy and dependable shield against bite-offs. Furthermore, stainless steel wire can also be employed in the construction of fishing rigs, such as spreader bars or wire traces, which find application in specific fishing techniques. Nonetheless, it is crucial to consider the precise type and thickness of stainless steel wire suitable for the targeted fish species and fishing conditions, to ensure optimal performance and safety.

- Q:What are the different wire surface coatings available for stainless steel wire?

- There are several different wire surface coatings available for stainless steel wire, each with its own unique properties and benefits. Some common coatings include: 1. Electroplating: This process involves depositing a thin layer of metal onto the stainless steel wire through an electrochemical reaction. Common electroplating coatings include gold, silver, nickel, and zinc. Electroplating can enhance the wire's corrosion resistance, improve its conductivity, and provide an aesthetically pleasing finish. 2. Powder coating: This coating involves applying a dry powder to the surface of the stainless steel wire and then curing it with heat to create a durable and protective coating. Powder coatings are available in a wide range of colors and finishes, providing both decorative and functional benefits. They offer excellent resistance to chipping, scratching, and chemicals. 3. PTFE (polytetrafluoroethylene) coating: PTFE is a non-stick coating that is known for its low friction properties. When applied to stainless steel wire, it creates a smooth and slippery surface, reducing friction and wear. PTFE coatings also offer excellent chemical resistance and can withstand high temperatures, making them suitable for various applications. 4. PVC (polyvinyl chloride) coating: PVC coatings are commonly used for stainless steel wire in applications where insulation or protection against moisture and chemicals is required. These coatings provide electrical insulation and can enhance the wire's resistance to abrasion and corrosion. PVC coatings are available in different thicknesses and colors to suit specific requirements. 5. Nylon coating: Nylon coatings offer similar benefits to PVC coatings, including electrical insulation and protection against abrasion and chemicals. Nylon coatings are known for their excellent resistance to impact and high strength. They are often applied to stainless steel wire used in industries such as automotive, construction, and marine. 6. Epoxy coating: Epoxy coatings provide excellent corrosion resistance and adhesion to stainless steel wire. They are commonly used in harsh environments where the wire is exposed to chemicals or extreme weather conditions. Epoxy coatings can also enhance the wire's durability and impact resistance. These are just a few examples of the many wire surface coatings available for stainless steel wire. The choice of coating depends on the specific application requirements, including corrosion resistance, electrical insulation, aesthetics, and environmental factors.

- Q:Is stainless steel wire resistant to abrasion?

- Indeed, stainless steel wire exhibits resistance against abrasion. Possessing remarkable durability and strength, stainless steel emerges as a formidable material, effectively combating wear and tear. Its distinctive constitution, comprising chromium and nickel, endows stainless steel with exceptional resistance to corrosion and bolstered strength. Consequently, stainless steel wire boasts a remarkable ability to withstand abrasion induced by friction, rubbing, or scraping against diverse surfaces. Given its invaluable resistance to abrasion, stainless steel wire finds extensive employment in fencing, construction, automotive, and marine sectors. It is indispensable in enduring harsh conditions and extending the wire's lifespan.

- Q:Can stainless steel wire be used for wire binding?

- Certainly, wire binding can indeed utilize stainless steel wire. Renowned for its robustness, longevity, and corrosion resistance, stainless steel wire proves to be an exceptional selection for wire binding purposes. It finds frequent usage in sectors like bookbinding, packaging, and construction, where a dependable and enduring binding solution is imperative. Stainless steel wire can be obtained in a range of thicknesses and can be effortlessly fashioned into loops or spirals, resulting in a polished and tidy binding outcome. Furthermore, it seamlessly integrates with a majority of wire binding machines, rendering it a versatile choice for binding documents, reports, presentations, and other materials.

- Q:Can stainless steel wire be used for making wire screens?

- Yes, stainless steel wire can be used for making wire screens. Stainless steel is commonly chosen for wire screens due to its durability, corrosion resistance, and ability to withstand high temperatures. It is an ideal material for various applications that require strong and long-lasting wire screens, such as in filtration systems, insect screens, and industrial sieves.

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang, China |

| Year Established | 2005 |

| Annual Output Value | Above US$1.6 million |

| Main Markets | Europe, North America. |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40% |

| No.of Employees in Trade Department | Above 30 people |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | Above 5000 square meter |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

201 2B Stainless Steel Strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords