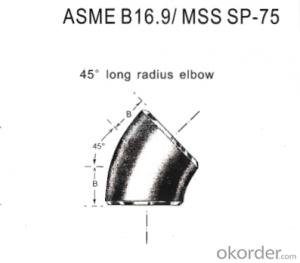

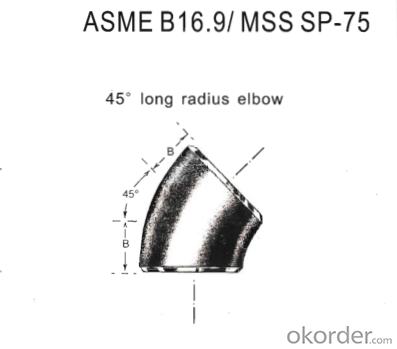

Carbon Steel Pipe Fittings Butt-Welding 45° Long Radius Elbows

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features standards and products of our butt welding fittings:

Features of butt welding fittings:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of butt welding fittings:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

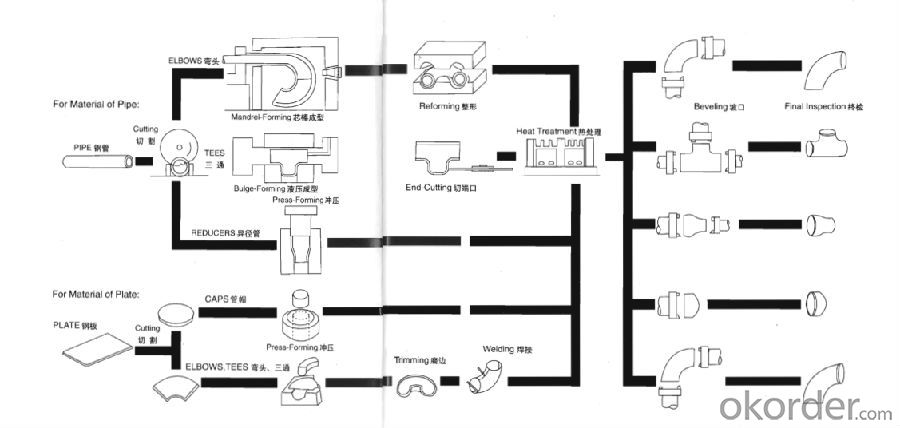

Manufacturing method and process:

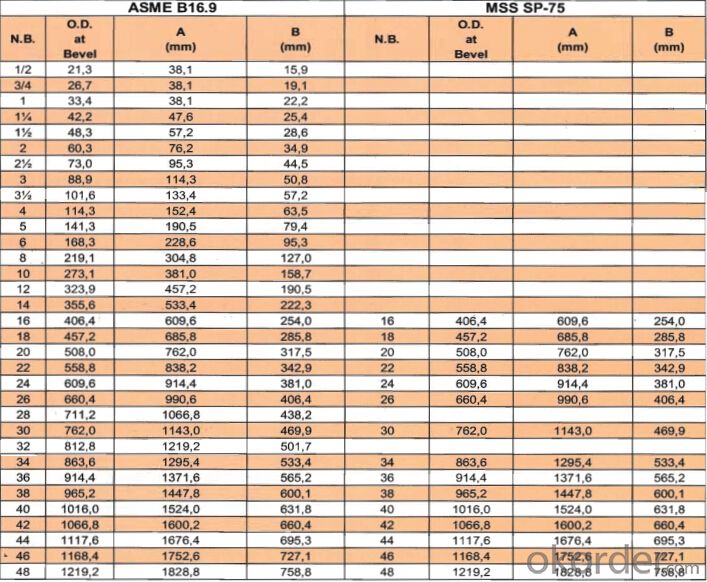

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

45° Long radius elbows:

Packing of butt welding fittings:

FAQ of butt-welding fittings:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:Lets say i am in 5th gear, i see some traffic ahead of me that is moving but its just really slow. I will downshift to 2nd, but i sometimes feel like the car is going to stall because it is going so slow. I do not want to full stop because the traffic IS moving, and i do not downshift to 1st. What do you normally do in this situation. It happens a lot to me during stop SIGNS. when i am waiting in line at stop SIGNS.another question is speed bumps: lets say i am in 2nd gear and i approach a speed bump. i start braking but as soon as i hit the speed bump my car starts to shake and rumble. should i press the clutch in as i go over speed bumps and just re-accelerate in the same gear? or what?

- i have to wear a face mask(1: im a goalie 2: i play on 14 and under) unless their wearing a face mask it seems pretty high.even with the mouth guard

- Q:What are the national standards for pipe connections (R (PT)) with tapered tubes at both ends? Thank you

- Because of this transition joints, because of doing too much, but do not know what the standard, and many times is an industry or business standards it? Normally, this is called a pair of silk. Relatively simple production, large dosage.

- Q:Would I just be able to clean it out with a non flammable cleaning substance, and let it air out for like a week?

- just keep cleaning it and you should be okay. maybe see the family doc for antibiotics if you notice any signs of infection.

- Q:can i cast polyurethane resin in a polymer modelling clay?

- I use A5 pure cotton paper which I buy from Original Crown Mill. It has a nice weight and takes ink well from a typewriter. My typewriter is a Baby Empire Aristocrat from the 1940's.

- Q:i am looking for a solid black face shield or a chrome face shield for my HJC IS-16 motorcycle helmet. i went on their website and only found ones i dont like such as pink, green, or smoke. I want solid black or solid chrome. where can i find these?

- You can try stacking them ontop of each other and putting a rubber type glue to hold them together.

- Q:Okay, 1st I've though of the most stupidest ideas that pretty much made me worried now. So this is what happend, after reading on how unsafe it was to pierce your lip with a safety pin, I didn't know so I just gone right on ahead and did it, I didn't brush my teeth but I washed my hands, I used rubbing alcohol to clean the safety pin and my lip ring, Okay I used two types of safety pins becuase one was smaller and it didn't fit so I put in bigger one (cleaned with alcohol) in the same hole, it went in and then I put in the lip ring, it was like a loop type lip ring, I put it in and it bled alittle becuase it seemed the loop didn't really fit in but it gone in, I cleaned it afterwards with alchole and proxide. Now I took along time to do it becuase I was nervous. So I checked it was safe.. it wasn't, I took it off asap, I garged proxide and cleaned both sides with alchole, it feels like alittle bubble inside my lip, it looks a bit clean though.. Please don't call me ignorant and help.

- Safety Switchboard Matting insulationmat.in/home/

- Q:I have this sniper it costed me 300 bucks ive had it for about a year and its fps is between 350-450 somewhere and i wanna know on a scale of 1-10 how good it is. We play hardcore airsoft and play in the wilderness with ghillie suits and we are playing pro so we can be firing up to 1000 feet away and tbh when i fire the sniper bullets go really fast starting out and they immedtialey drop in the middle of the air like a dive bomb anyways is 350-450 for a airsoft sniper good for hardocre long range playing in the wilderness?

- Great question! It really does provoke a double standard here amongst the answers. I think I would if I thought someone was getting hurt, I would have to. I would not like to have that on my conscience. Especially if I knew there were kids in the house! I would hope that the police intervention would be a wake up call for the abuser. I don't know if that would change anything in most cases though.

- Q:does anyone know where I could locate this item .I have exhausted all my sources(stores)

- 1/8 inch layer will make it so anyone wanting to get the picture off will have to use a razor blade or knife to carve it out. 1/4 in layer and they'll need a saw!

- Q:Quick history I am remarried to DD stepdad for 3 months.was seperated from her dad for 2 years.we moved in with stepdad after the wedding, about 3 months now. In the past 2 months DD has wet herself 3 times.Once was at night, once was coming out of the pool, once was coming home from the park.She also did this a few months ago when my dad was in the hospital.She just stood in the hall and peed.Dad has since passed away and we have moved in with new husband and stepfamily.There are 7 of us all together now where before there was only she and I.Could this all be attributed to the changes in her life? Am I not paying enough attention to her? Any advice will be helpful.

- sure as a count of actuality final Friday. I almost have been given suspended yet I made some reliable excuse approximately how i thought there replaced right into a hearth and that i only had to pay a superb and that replaced into it. :D

- Q:im going to dublin in begining of march for a holiday with my wife and 2 kids..i wish to discover interesting places like mountains, nice scens, entertaining ect..i have 7 nights there where i wish to make 2 or 3 nights in dublin and the others going more into ireland..can you please suggest me good places and a good route from where to begin and endpls send me on borgr080gmail will appreciate a lot your help.

- Why do you think the factory puts on normal size wheels instead of chrome plated wagon wheels? You can have wheels that look stylish, that everyone will laugh at two years from now, or you can have a safe, comfortable ride.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Steel Pipe Fittings Butt-Welding 45° Long Radius Elbows

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords