Carbon Steel Forged Nipple with API standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Carbon Steel Forged Nipple Description

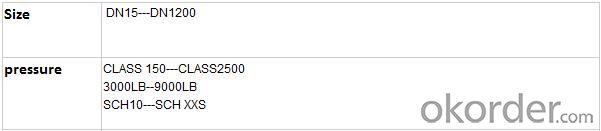

Size: DN15---DN1200

Pressure: CLASS 150---CLASS2500, 3000LB--9000LB, SCH10---SCH XXS

Material: Carbon steel (A234 WPB, ASTM A105), Alloy steel (A234 WP22, WP11, WP9), Stainless steel (A182 F304/316L/347/321)

Face type: Bevel end, Plain end

Standard: ASME, BS, EN, GOST, AS, SAS, UNI

Certificate: ISO9001/2000, BV, API, CE, DNV, TUV

Packing: Wooden case and Pallet

2. Main Features of Carbon Steel Forged Nipple

1) Advanced test for quality

2) MTC provided

3) Good price and service

3. Carbon Steel Forged Nipple Images

4. Carbon Steel Forged Nipple Specification

5. FAQ of Carbon Steel Forged Nipple

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

One of the leading manufacturers and suppliers specializing in this product in China, supply a wide variety of accessories consists of our one-stop sales. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q:Will the alarm still go off

- in my opinion i bypass with the Harley. Rule of thumb is you in no way promote your Harley, yet truth is we are able to not all have a storage complete of them and albeit they don't run like a dream forever. With that stated convinced a harley prices more beneficial off the floor then different producers even if the resale fee and demand are a lot more beneficial then different producers. there is also the information-set that driving a harley brings. imagine how people look at the same time as 10 Yamaha's experience down significant highway, now imagine the seems at the same time as 10 Harley's rumble down significant highway. If reliability and luxurious are your significant purpose, do no longer purchase a Harley. My 00 sportster had 2 rebuilds through 06. My new Dyna has had some manufacturing unit subject matters yet Harley is tremendous about getting it dealt with. The 00 historic previous has 90K miles with minor restore needing. So ya the Harley can do it even if that is a uncommon tale no longer a worry-loose tale. nevertheless strong yet no longer forever. have you ever talked about what percentage different producers take on the look of the game traveling Harley's? that asserts lots, all of them wanna be a Harley at the same time as they improve up. Me I experience an 07 Dyna (Harley), as a small woman rider i'm getting a ton of double takes and may want to on any motorbike, yet you do not hear oh guy that hottie rides a motorbike, you hear that hottie rides her own Harley :-)

- Q:I am using Avery (product number 18660) address labels and I am doing everything right in Word 2007 in order to print them out. Once I start printing them, the addresses print all the way towards the top and they shouldn't be. The margins are already set correctly because when I printed it on regular white paper, it did so correctly. WHY IS IT DOING THIS?! Let me know what I can do to fix this. THANKS!!!

- Always discard disposable gloves after they're use.

- Q:My drive writes fine on Verbatim brand discs but it refuses to write the same files on Memorex or HP brands. Please help.

- I think it sounds awesome! You can paint them or leave them steel grey. Never worry; creativity is a gift, so go with your gut, mom.

- Q:Hydraulic pipe quick coupling principle of hydraulic pipe joint

- JB/T6381 ~ 6385-1992 burking hose connector has the advantages of convenient installation, but added a tightening process. After the hose is damaged, the joint coat can not be reused, and it is made up of a steel wire braided hose. The utility model can be connected with a welding pipe joint sealed with a O ring. Pipeline system suitable for oil, water and gas as medium. Medium temperature: Oil: -30 ~ 80 degrees Celsius; air, -30 ~ 50 degrees Celsius; water, 80 degrees below JB/ZQ4427 ~ 4428-1986, three valve type hose joint assembly, do not need to remove the rubber tube of the outer layer. A slightly different diameter of hose hose, hose on the joint coat of pre compression to compensate. Hose pre compression in 31% ~ 50% range to ensure no leakage under the pressure of work, will not pull glue, cover does not break. With the welded pipe joint, quick joint, sleeve type pipe joint used for oil, water and gas pipeline system for medium, working pressure, medium temperature by connecting hose limited JB/ZQ4429 ~ 4431-1986 quick change connector (both open and closed) tube apart and self sealing pipe. In the liquid will not be lost, so it is suitable for frequent disassembly occasions. The structure is complex, and the local resistance loss is greater. Suitable for oil and gas pipeline system for medium, the working pressure is lower than 31.5MPa, the medium temperature of -20 to 80 DEG JB/ZQ4434-1986 quick change connector (both ends open) for oil and gas pipeline system for medium, the working pressure of medium temperature according to connecting hose limited JB/ZQ4435-1986

- Q:Which gospel choirs, which bluesmen, which jazzers - who???

- Copper pipe will have a reaction with any kind of iron or steel pipe, galvanized or not. You cannot easily clean encrusted deposits. You can take valves and fittings apart to scrape or brush them clean. There shouldn't be any deposits on the interior wall of copper pipes, so you don't have to go to a lot of trouble trying to clean the interior of it. Old galvanized pipes - they corrode over time, on the inside, and I would replace them.

- Q:I have a brand new 3 ton unit. (house 1350 sq ft) I had all my duct work replaced. Both inside and outside units run but my house is very hot. There is R 30 insulation in the attic, too. I need to be cool and stop wasting electricity. Help please.

- No, because each party has a right to do business (or not do business) with each of the other parties.

- Q:Okay every alarm in the house has been going off for an hour and its making carbon monoxide ? Whats going on ? I know theres no carbon monoxide cause i'd probably be dead by now

- It is a brand name for a compression fitting to connect to metal tubing. Actually it is spelled Swagelok.

- Q:What would happen if I did that? ;-p

- EDIT: .8c relative to what? The ground observer? I think I answered too quickly without thinking this through. EDIT (2): OK, I thought about it some more. Since there is no acceleration going on, the two frames are equivalent. The speed of the car as measured by a ground observer is the same as the speed of the ground as measured by the driver. Has to be - both frames are inertial and neither frame is the master reference. So, if the ground observer sees the car pass at .8c, then the driver sees the earth pass at .8c. They will both see time and length differently in the opposite frame than the other observer, but they will both see the opposite frame passing at .8c. The speedometer is just the way that the driver measures the speed of the passing earth. It should read .8c. I think that's right.

- Q:Why does the air conditioner outdoor pipe joint freeze and freeze in case of refrigeration?

- Fluorine slightly more: thick pipe icing or frost, because the refrigerant inside the machine is not completely vaporized, back to the end is still vaporized heat absorption.Excessive dust in the inner filter screen or evaporator: the internal air circulation is not smooth, resulting in the backflow of the subcooled refrigerant, the icing of the thick pipe, and the cooling effect.

- Q:I wear swim shorts to bed, and one time, there was friction as I was laying down and it made a spark. What do I do? Is it a fire hazard? Can I die?

- Kill as many as possible with machine guns and chop their heads ,im going to stay on the move and not hide out in one spot for them to crowd around.Family will stick together and maybe jack a plane or something to an area less populated with zombies. Id suggest everyone fight and not run and hide you might step outta that rv and there be no survivors only zombies then what

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Steel Forged Nipple with API standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products