Antiseepage Material 0.75mm HDPE Geomembrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Description:

1.used in landfill caps.

2.secondary containment for above ground tank farms

3.as well as within various other containment structures such as dams, canals, ponds, rivers and lakes.

Our product was proved as good physical performance, puncture, aging, ultra-violet radiation, oil and salt, alkali and corrosion resistance

, high and temperature resistance, anti-seepage and damp proof effects, complete width and thickness specifications, low cost and simple

construction.

2.Product Characteristic:

1), Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2), Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3), Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.)

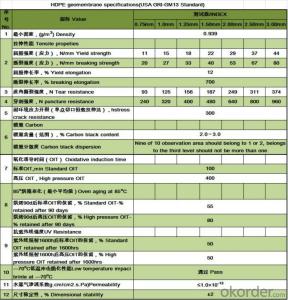

3.Product Specifications:

1.Thickness : 0.75mm,

2.Length: 50 m -100 m ; width: 1 m -8 m ( according to customer needs )

3.Longth:50-100m(at request)

4.Material: HDPE.

5.Color: Black or as required

4.Reference Picture

- Q:What is the diatomite craft?

- Diatomite is a kind of siliceous rocks, mainly distributed in China, the United States, Denmark, France, Romania and other countries. It is a kind of biogenic siliceous sedimentary rocks, mainly composed of the remains of ancient diatom. Its main chemical composition is SiO2, written as SiO2 · nH2O, and the mineral compositions are opal and its variants.

- Q:What is the power of electric heating film

- Minimum one is 8000 Watt per square 80 watt , and maximum one is 130 watts per square, 13000 Watt in total, maximum and minimum installation depends on the production of insulation. That is to say, less pavement is needed if insulation performance is good, on the contrary, the actual wattage is the half of consumption of actual day.

- Q:Can geomembranes be used for floating covers?

- Yes, geomembranes can be used as floating covers. Geomembranes are impermeable and flexible materials that are commonly used for containment purposes. When installed properly, they can create an effective barrier on top of liquid surfaces, such as ponds or reservoirs, preventing evaporation, contamination, and providing insulation. Therefore, they are suitable for use as floating covers in various applications.

- Q:does the skylight of the car stick membrane?

- it can stick.The vehicle roof is the main heat source radiation area of the air temperature in the car. It can obviously improve the driving environment and reduce the energy consumption of the air conditioning, so as to achieve the effect of energy saving. After skylight glass sticking membrane, due to the effective barrier to ultraviolet light, the car interior is kept from radiation and achieve the effect of prolonging the service life. .

- Q:what's the paving method of composite geo-membrane?

- Geomembrane pavement is divided into channal bottom paving and slope paving two sections. pavement method: Horizontally roll along the channel axis direction. Slope pavement, after qualified acceptance of slope, rool it along the slope axis direction, the joint with the channal bottom composite geo-membrane uses t-shape connection.

- Q:Can geomembranes be used in canal lining?

- Yes, geomembranes can be used in canal lining. Geomembranes are impermeable materials that provide a barrier against water seepage and are commonly used in various civil engineering applications, including canal lining. They help prevent water loss and increase the efficiency of water conveyance systems by minimizing leakage through the canal walls.

- Q:What is the operating principle of the vacuum laminating machine?

- The laminating machine must be the plastic packaging machine. The working principle is to insert the materal (or paper) to be plastic coated into the special plastic package, put the material into the plastic packaging machine, melt and solidfy the adhesive of the plastic package by heating and pressing and exhaust the air at the same time. By then plastic packaging is completed.

- Q:How do geomembranes perform in high altitude areas?

- Geomembranes perform well in high altitude areas as they are designed to withstand extreme conditions such as low temperatures, high UV radiation, and strong winds. The materials used in geomembranes are typically highly durable and resistant to degradation, ensuring long-term performance even at higher altitudes. Additionally, geomembranes are impermeable, providing effective containment and protection against water and chemical leakage, which is crucial in high-altitude environments where water scarcity and environmental protection are of utmost importance.

- Q:How to calculate the power consumption of the electric heating film?

- In electricity, it is able to reach the normal temperature in the initial half an hour. The heating power is 220W, reaching the set temperature, if 100 square meters of heating area (construction area of about 130 ~ 150 square metre) count laying 59 square meters of electrothermal membrane computing, 220V voltage normal usage rate according to: 102W (using the thermal insulation material case) initial full load power 220W.

- Q:How to tear off the plastic wrap?

- There is a serrated knife on the plastic wrap box! Tighten it in the opposite direction. When there is a hole on the saw blade, it will be torn off easily. If you use stripped-down film roller, stroke it with a single-sided blade and it will be torn off easily.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Antiseepage Material 0.75mm HDPE Geomembrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords