Aluminum Sulfate Low Fe First Grade Best Quality in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Chemical and Physical Properties:

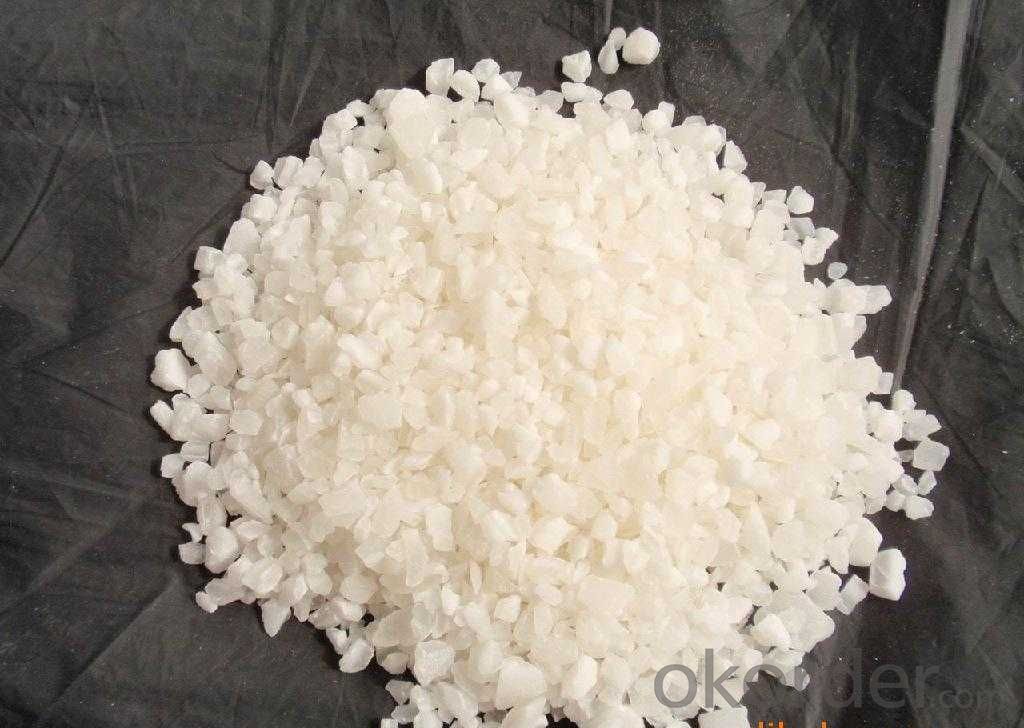

Product name: Aluminium Sulphate or Aluminum Sulfate

Shape: Flakes or Granular or Powder.

EINECS NO.:233-135-0

CAS No.: 10043-01-3

HS.Code: 28332200

Molecular Formula: Al2(SO4)3

Appearance:It is white or grey flake,particle or massive crystallization.

Apt to cake after moisture absorption when laid in air for a long time.A little green because of Fe2+ ,yellow when Fe2+ is oxided to Fe3+.Soluble in water easily,and water solution is acid.

2. Specification:

Standard: HG/T 2225-2001 and HG/T 2227-2004

Items | Specifications | |||

I Type:Low Ferrous/Low Iron | II Type:Non-Ferrous/Iron-free | |||

First Class | Qualified | First Class | Qualified | |

Al2O3 % ≥ | 15.8 | 15.6 | 17 | 16 |

Ferrous(Fe )% ≤ | 0.5 | 0.7 | 0.005 | 0.01 |

Water Insolube % ≤ | 0.1 | 0.15 | 0.1 | 0.15 |

PH (1% aqueous solution) ≥ | 3.0 | 3.0 | 3.0 | 3.0 |

Arsenic(As) %≤ | 0.0005 | 0.0005 | ||

Heavy metal (Pb) %≤ | 0.002 | 0.002 | ||

3.Applications:

Water effluent treatment system

It's used for purification of drinking water and wastewater treatment by settling of impurities by

means of precipitation and flocculation.

Paper Industry

It helps in sizing of paper at neutral and alkaline pH, thus improving paper quality (reducing spots

and holes and improving sheet formation and strength) and sizing efficiency.

Textile Industry

It is used for color fixing in Naphthol based dyes for cotton fabric.

Other Uses

Leather tanning, lubricating compositions, fire retardants; decolorizing agent in petroleum, deodorizer; food additive; firming agent; dyeing mordant; foaming agent in firefighting foams; fireproofing cloth; catalyst; pH control; waterproofing concrete; aluminum compounds, zeolites etc.

4. Package:

Packaging Detail: PP/PE 50kg/bag;25kg/bag;Jumbo bag or according to customers' requirements.

20-25MT will be loaded in per 20'FCL container.

5. Attention and Storage:

The product is liable to absorb moisture and clot due to long-term exposure, so shady, cool and ventilated environment is needed.

- Q:Always speeds the reation ratedoes not affect the reation rateundergoes a chemical changedoes not become part of the chemical changealways slows the reation rate

- The best answer is speeds the reaction rate. Generally it lowers the activation energy so that the reaction can proceed easier. Enzymes can be considered catalysts in the body that allow digestion to occur at a temperature like body temp, where it would go faster at a higher temp.

- Q:Chemical catalyst system baa?

- Can speed up or slow down the reaction rate without participating in the reaction of the material

- Q:Chemical Reactions Under what circumstances the catalyst accelerates the reaction

- First, more than ninety-nine percent of the catalyst is accelerating the reaction, and if the catalyst kinetics reduces the energy barrier of the reaction, the reaction will naturally accelerate.

- Q:What is the similarity between enzymes and general chemical catalysts?

- (1) The enzyme is the same in many respects as a biocatalyst and a general catalyst, such as a small amount and a high catalytic efficiency. As with the general catalyst, the enzyme can only change the rate of chemical reaction and does not change the equilibrium of the chemical reaction It is possible to catalyze the activation of a large number of substrates in a short time and to reflect the high efficiency of enzyme catalysis.The enzyme can reduce the activation energy of the reaction (activation) (△ G) during the reaction, but the reaction rate is accelerated and the reaction time is reduced, but the equilibrium constant is not changed. (2) However, the enzyme is a biological macromolecule (1) Enzyme-catalyzed high efficiency: The catalytic effect of the catalyst can increase the reaction rate by 10 ^ 6 ~ 10 ^ 12 times, which is at least several times higher than that of the conventional catalyst. (2) The enzyme catalyst Highly specificity: including specificity of response, substrate specificity, chirality specificity, geometric specificity, etc., that an enzyme can only act on a certain class or a specific substance. Bond, ester bond, peptide bond and so on can be catalyzed by acid-base hydrolysis, but the hydrolysis of these chemical bonds are different, respectively, the corresponding glycosidase, esterase and peptidase, that is, they were specific (3) enzymatic reaction conditions are mild: enzymatic reaction is generally carried out in aqueous solution of pH = 5 ~ 8, the reaction temperature range is 20 ~ 40 ℃

- Q:hey people i need your help about my science lab report...the question on my paper says "what function the catalyst?....please help me on this one...i would really appreciate if you leave me answers....much mahalos to all you folkss...thanks

- The answer above mine is correct. You should also note that a catalyst does not take part in the reaction: it just makes things easier as the previous person said.

- Q:and what type of macromolecule are they made of? thanks!

- by definition a catalyst is a substance that alters the cost of, or makes accessible, a chemical or biochemical reaction yet maintains to be unchanged on the tip of the reaction. Enzymes are the only organic biochemical catalysts. Ribozymes are a particular sort of enzymes. certainly, the definition of enzyme rates: organic and organic catalyst produced in cells, and able to dashing up the chemical reactions mandatory for all times. they're great, complicated proteins, frequently soluble, and are noticeably specific, each and every chemical reaction requiring its very own specific enzyme. The enzyme's specificity arises from its energetic website, a community with a shape such as portion of the molecule with which it reacts (the substrate). the form of the enzyme the place the chemical binds in straightforward terms facilitates the binding of that distinctive chemical, such as a particular key in straightforward terms working a particular lock (the lock and key hypothesis). The enzyme and the substrate slot jointly forming an enzyme–substrate complicated that facilitates the reaction to ensue, and then the enzyme falls away unaltered. In prepare maximum catalysts are used to velocity up reactions. There are different non-organic and organic catalysts. maximum of that are utilized in industry and are commonly transition metals or their compounds.

- Q:pls give one or two catalysts that are used in the industry for example:Rhodium catalyst in a catalytic converter of a car or the Iron catalyst for making ammoniaTHANKS :)

- u . s . a . of america has an excellent style of organic gas. In theory that's accessible to have an electric powered motor force a compressor to take the low stress gas to make it dense adequate to get adequate interior the vehicle to run for a mutually as (in actuality, gas stations with organic gas pumps do it precisely like that, that's no longer trucked to them, we've a pair in Dallas) the real undertaking is that, specific it will be pressurized, requiring a greater perfect tank than propane, that's a liquid interior the tank, and the tank must be a cumbersome cylinder for capability or numerous smaller cylinders area by making use of area. Getting this into the physique of the vehicle devoid of doing away with all the storage/bags area isn't ordinary. And ultimate efforts nevertheless finally end up with the miles in line with fill up being decrease than the gas which inserts in a small area.

- Q:Carbon dioxide and hydrogen in the catalyst and heating conditions, the reaction of water and methane, the chemical equation is what

- CO2 + 4H2 = catalyst, heating = 2H2O + CH4

- Q:In the chemical reaction will have to use the catalyst reaction, such as H2O2 === (MnO2) H2O + O2 ↑, then the catalyst in the end to participate in the reaction (that is, the catalyst itself is the reactant) If so, why are some of these substances in the reaction (these substances refer to the catalyst) in the reaction after the quality and nature of the change does not change?

- In the chemical reaction can change the chemical reaction rate of other substances (both can also improve), and its own quality and chemical properties in the chemical reaction before and after the material did not change called catalyst (also known as catalyst)

- Q:Hydrogen and nitrogen in the high temperature and pressure and catalyst conditions for the synthesis of ammonia chemical equation

- 3H2 + N2 catalyst iron ---> 2NH3 conditions high temperature and high pressure

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Sulfate Low Fe First Grade Best Quality in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords