Alkali resistant glass fiber roving apply in the fireplace of refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

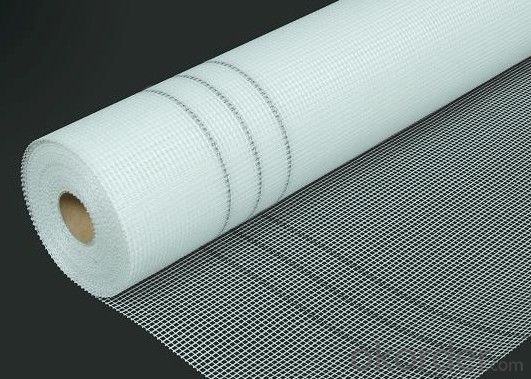

| Place of Origin: | China (Mainland) | Brand Name: | glass fiber cloth | Model Number: | Glass fiber Woven Roving |

| Application: | Wall/Roof covering Cloth | Weight: | 430g-2500g/sqm | Surface Treatment: | Silicon Coated |

| Width: | 30mm-20000mm, 30mm-20000mm | Weave Type: | Plain Woven | Yarn Type: | E-Glass |

| Alkali Content: | Alkali Free | Standing Temperature: | 550 | Color: | white |

| woven style: | plain woven | Glass type: | E-Glass | temperature: | 550 |

| Surface treatment: | silicon coated | Length: | 100-200m | fiberglass Woven Fabric *: | fiberglass Woven Fabric * |

| Brand: | glass fiber cloth

| unit mass: | 400g/600/800g |

Packaging & Delivery

| Packaging Details: | container |

| Delivery Detail: | 10days upon the buyers' payment |

Specifications

Glass fiber Woven Roving for automoblie parts

1.wide applications

2.High quality with best price

3.width can be demand

Products Features and Advantages

1.Well-distributed, even tensile strength, good vertical performance.

2.Fast impregnation, good moulding property, easily removing air bubbles.

3.High mechanical strength, less strength loss in wet condition.

- Q:Glass wool and pef air conditioning insulation material, which one is better?

- So many air-conditioning installation company will choose this new PEF thermal insulation cotton and rubber and plastic thermal insulation material. Generally many companies prefer to use PEF thermal insulation cotton for duct, and rubber and plastic thermal insulation material for water pipes. Productions can be selected according to each person's favor, but we can't only select the cheap products when selecting, and we should choose guaranteed green products.

- Q:Is the glass wool sound insulating? How good is it?

- Glass wool glass fiber is a kind of inorganic fiber in the category of glass fiber.The glass wool is of corrosion resistance, chemical stability, low thermal conductivity, low bulk density, thermal insulation and good sound-absorbing property. Besides, the chemical composition of glass wool is glass.

- Q:what is the specification of glass wool sound-absorbing board?

- General specifications include 600 * 600600 * 500 * 1200-1200/12000300/400 mm thickness is usually 14 to 22 mm. . But different production capacity depends on the specific manufacturer, the manufacturer without certain production capacity can't do the bar plate or reach the thickness.

- Q:Does rock wool look like glass wool ?

- Glass wool is made through high temperature melting of industrial waste glass, and then making glass into flow by high-speed centrifuge, pulling glass flow into fiber under high temperature and high speed. Rock wool is inorganic fiber made by base materials of fine basalt after high temperature melting in high-speed centrifugation equipment. Glass wool is more economical and environmentally friendly than rock wool.

- Q:Who knows the construction scheme of external wall thermal insulation glass wool ?

- Glass wool external wall thermal insulation construction scheme 2 main material preparation: A, glass wool insulation board (80mm thick) (30mm thick) B, anchorage (8X120) mm plastic rose nail C, sample plate. This place belongs to south podium buildings, where large-scale construction can only be carried out after checking and confirming of supervision main contractor from Party A . 3.6 Pre-construction preparation 3.6.1 Set control lines in necessary parts of the building external wall internal and external corners, holes and deformation joints and rustication. Snap the horizontal ink line on the holes of door and window, and the glass?wool?board in first procedure while controling levelness in construction. Set the horizontal control line in places with two vertical control lines to control the flatness in construction of glass?wool?board. 3.6.2 Except for the solid wall, the wall surfaces should be coated with cement mortar and the flatness, intensity and verticality of mortar surface should meet the requirements of relevant specification. Base plane should be smooth, firm, dry, clean, water and alkali resistance, chalking resistance, PH value

- Q:Is the glass wool poisonous,

- But long-term inhalation of glass wool is certainly harmful to the body, because the glass wool is made of glass fiber, long-term inhalation of a large number of glass fiber,

- Q:What kind of glass wool is used for most buildings?

- Ask the dealer for product descriptions, and you can search its specifications and parameters and then design based on the performance specifications of specific products. I suggest you first determine which brand of thermal insulation cotton to use, or check if the number is in the tolerance range of national standards of the manufacturers, of course, it is a relatively wide range. I recommend Owens Corning ultrafine glass fiber insulation cotton.

- Q:How about the sound insulation performance of glass wool felts?

- Fix the glass wool in the wall with pegs, then cover it with plywood, after laying up with wooden surface, nail the wood again.

- Q:What's the difference between the rock wool and glass wool?

- Glass wool belongs to a category of glass fiber, and is a kind of man-made inorganic fiber. Taking quartz sand, limestone, dolomite and other FIR stone as main raw materials, and is melted into glass after mixed with some pure alkali, sodium borate and other chemical raw materials. In melting state, transfer them into flocculent fibers under the effect of external force, fiber and fiber are in three-dimensional crossing and winded with each other, presenting many little gaps. The gaps can be regarded as air voids. Therefore, glass wool can be regarded as porous materials, it has good heat insulation and sound absorption performance. Glass wool is a kind of spongiform material shaped by making melten glass fibering, it's chemical content belongs to glass and is a kind of inorganic fiber. It has good molding, small bulk density, low thermal conductivity, good thermal insulation and heat insulation, good sound absorption, corrosion resistance and stable chemical performance.

- Q:What are the standards of glass wool board?

- Common specifications are 1000 * 600 1200 * 600 with the thickness of 5-10cm and 3-5cm. It can be customized.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Alkali resistant glass fiber roving apply in the fireplace of refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords