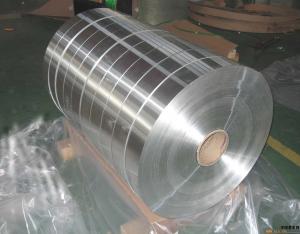

Thin Strips of Aluminum Al+Pet+Ldpe Insulation and Bubble Foil Mylar Film

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Features high peel adhesion with good tack, temperature and aging resistance, and water vapor resistance

Aluminum Foil Tape Features:

1) High tensile strength aluminum foil made from special aluminum

alloy, coated with aggressive solvent-based acrylic adhesive,

which provides high peel adhesion and quick sticking

2) Designed for sealing joints and seams of foil jacketing in

air-conditioning duct work

Specifications:

1) Foil thickness: 18, 22, 26μ

2) Roll width: 48, 50, 60, 72, 75, 96, 100mm

3) Roll length: 27, 30, 45, 50m

4) Log roll: 1.2 x 45m, 1.2 x 50m

5) Jumbo roll: 1.2 x 1200m, 1.2 x 1000m

Inner packing:

Cut roll: printed core and shrink wrapping

Log roll: cardboard wrapping

Jumbo roll: plastic film + corrugated board wrapping

Outer packing:

Cut roll: carton

Log roll: carton + pallet / wooden case

Jumbo roll: wooden case

Aluminum foil tape has many uses in the electrical, HVAC and construction industry. It can be used in

the jobs requiring moisture and chemical resistant, thermal conductivity, flame resistant, heat and

light reflectance, and weatherability. There are several different styles of tape avaiable. Including

acrylic adhesive, line-less, polymer coated and flame resistant aluminum glass tape.

Foil tape with an acrylic adhesive is used for sealing off vapors in fiberglass duct board, sheet

metal ducts and FSK systems, It is ideal for use in HVAC systems. Due to its high tack cold weather

acrylic adhesive, which helps it to adhere well, even in periods of low temperature and high humidity.

- Q:What effect does the aluminum pulley bring to the belt?

- Belt pulley with aluminum, absolutely assured, at present most of the design belt pulley, all with aluminum

- Q:Can the high frequency of aluminum band replace the high frequency of professional high-power loudspeaker box?

- The same volume, sound intensity, ribbon horn may have burned out, and horn speakers have not worked out.

- Q:How much is the small aluminum belt excavator?

- Small crawler excavator about the weight and its model similar to it, such as 55, weight is about 5000kg, 60 6000kg around, 70, 80 type are similar. Price well, domestic relatively cheap, 50 type 20 to 300 thousand, 60 type is also 380 thousand to 400 thousand, 70 type of 400 thousand to 600 thousand and 80 Komatsu seems to be the lowest 600 thousand. It's all mine. Not very clear about this market

- Q:Would you like to buy a sensor for measuring the thickness of aluminum ribbon?

- ZTMS08 system has been optimized through performance and field calibration, and its main technical specifications and performance parameters comply with the relevant regulations. It can be widely used for thickness measurement of paper, paperboard and other sheet materials.

- Q:How to use batteries, magnets, cans of aluminum belt to make a rotating aluminum belt device, please explain

- On the left is an aluminum can top. It is on a vertical shaft and can rotate freely. On the right is a used water pen holder, the same on the vertical shaft, you can freely rotate.

- Q:How can the aluminium band be welded to the steel shell?

- If it is more than 0.5 mm by resistance heating welding, welding materials need to use the 303B welding wire Odin wei.Welding tools: carbon block welding, welding with two electrodes.

- Q:What is the difference between cold rolling and hot rolling of aluminium plate and aluminium strip? Which kind of aluminum plate is good? Speak a little more popularly

- Not appearing in spots. Suitable for mirror surface, spray coating. Hot rolling is more expensive than cold rolling

- Q:Aluminum band treble sounds good?

- The high pitched sound field of an aluminum band is shaped by a longitudinal distribution, so it is good to remove the axle.

- Q:Why is the president of aluminum strip mildew, will affect the performance of the transformer?

- Can test the resistance, running temperature and other indicators, and the provisions of the comparison.

- Q:25 square metres of aluminium wire. Can you bring up 4 sets of two air conditioners?

- According to the load calculation, 4 sets of two air conditioners, as long as the wire reached 8 square, you can drive. Your 25 wire can drive. But it is recommended that you use copper wire as a guide wire. The quality and service life of the copper wire is much better than that of the aluminum wire.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Thin Strips of Aluminum Al+Pet+Ldpe Insulation and Bubble Foil Mylar Film

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords